Full-automatic forming machine for L-shaped line

A fully automatic, forming machine technology, applied in the field of wire rod rolling equipment, can solve problems affecting the ductility and toughness of wire rods, uneven deformation of steel wire rods, and unstable processing quality, so as to achieve stable molding quality, improve production efficiency and Molding effect, the effect of reducing the risk of work-related injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

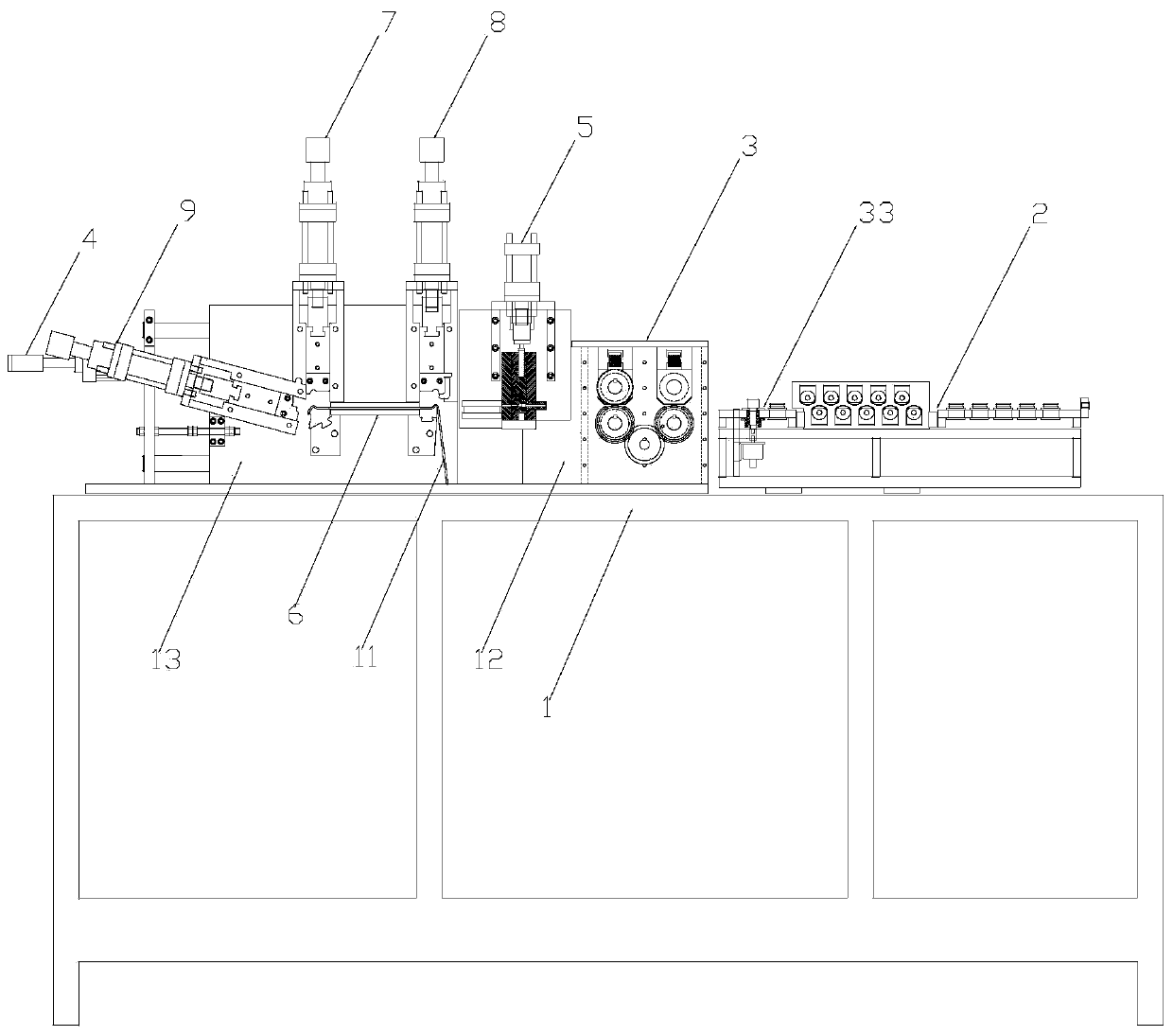

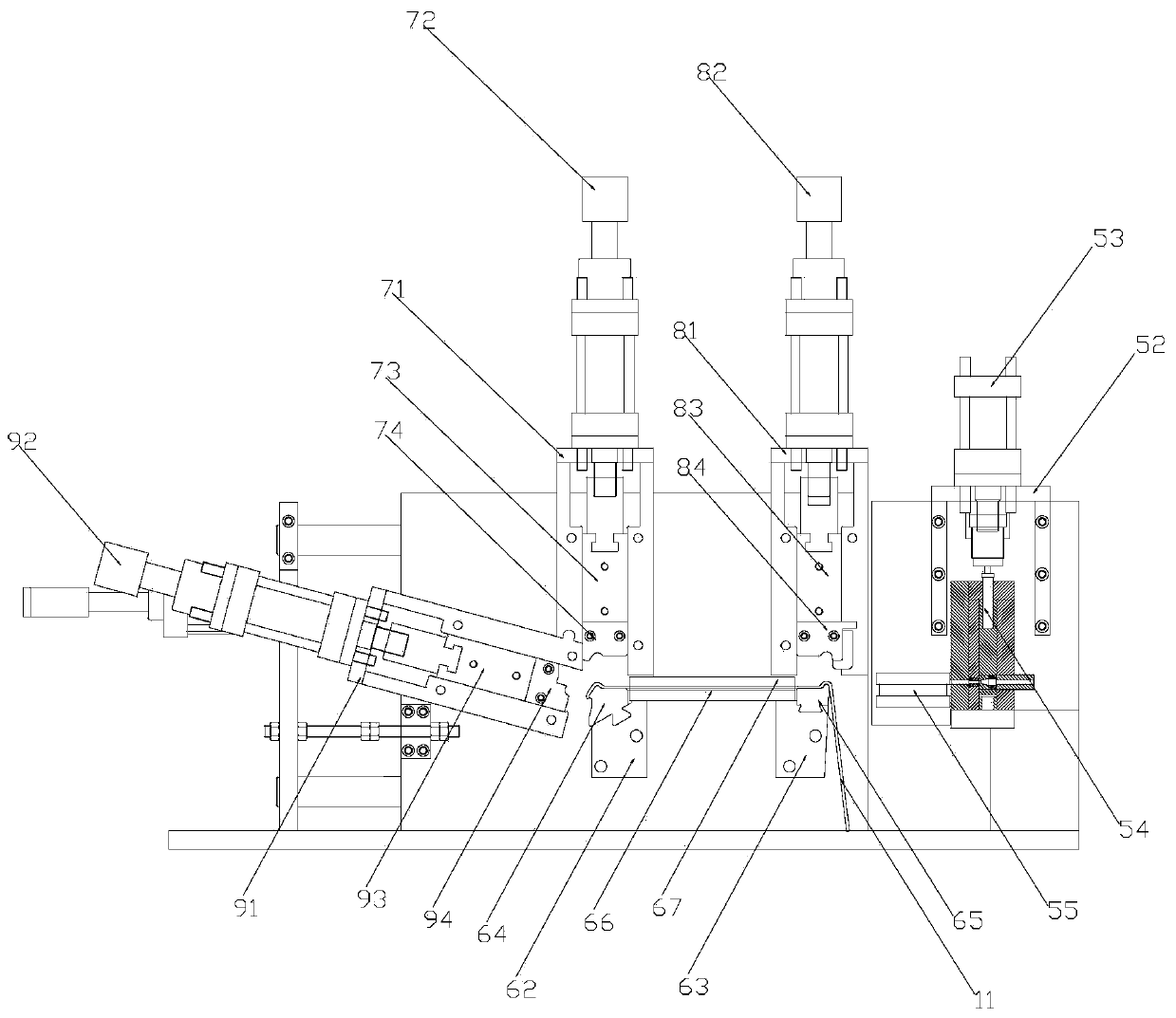

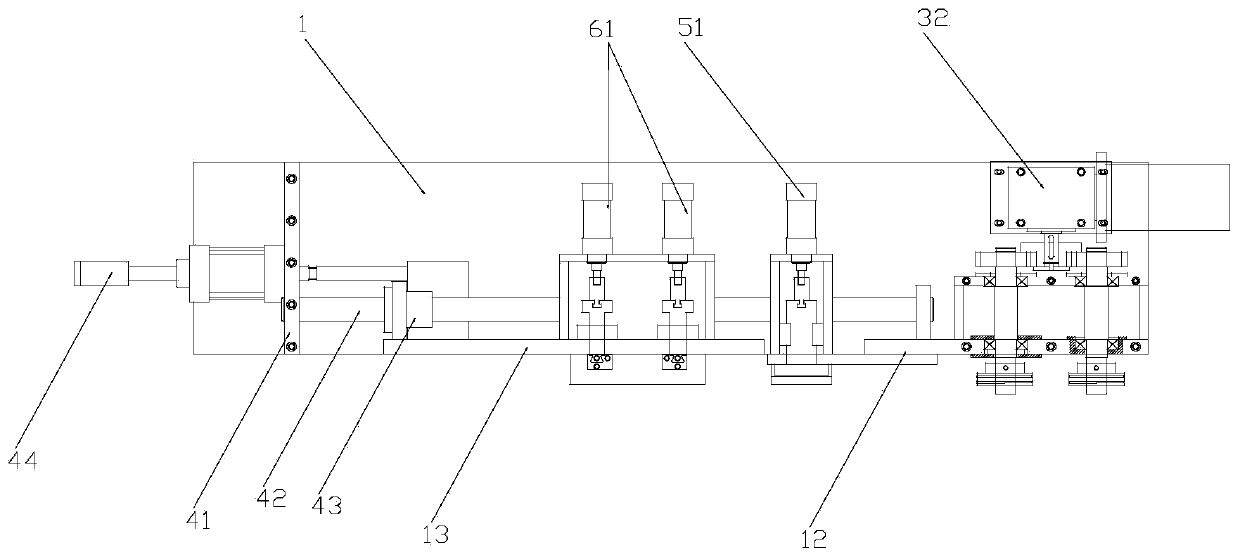

[0020] Such as figure 1 , image 3 , Figure 4 As shown, the L-shaped wire automatic forming machine of the present invention includes a frame 1, and one end of the working surface of the frame 1 is provided with a wire adjustment mechanism 2 for straightening and flattening the wire rod 11. The wire mechanism 2 includes a horizontal pinch roller set 21 and a longitudinal pinch roller set 22. The crimping openings of the horizontal pinch roller set 21 and the longitudinal pinch roller set 22 are on the same level. There is a wire nozzle 23 at the end, and the wire outlet side of the wire adjustment mechanism 2 is installed on the working surface of the frame 1 with a wire mechanism 3 for conveying the wire 11. The wire pulley group 31 whose outlet is on the same horizontal plane, the wire pulley 31 and the rolling vertical plate 13 are on the same working plane, and the back of the wire pulley 31 group is equipped with a driving motor 32, and the wire pulley group 31 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com