Full-automatic two-dimensional wire bending forming machine

A fully automatic, forming machine technology, applied in the field of wire processing equipment, can solve the problems of poor forming effect, high welding cost, and many working hours, and achieve the effects of reducing the risk of work-related injuries, compact structure, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

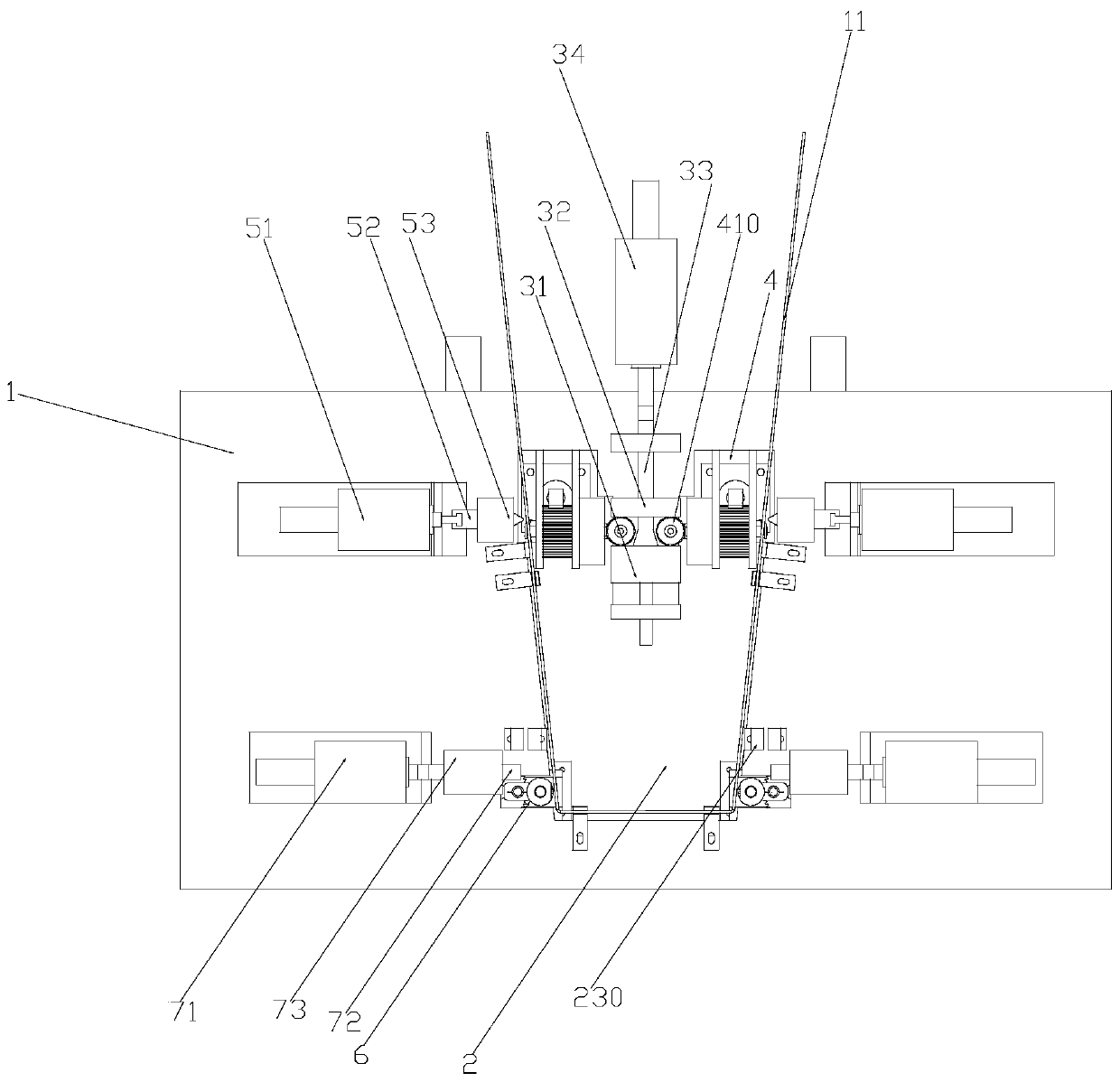

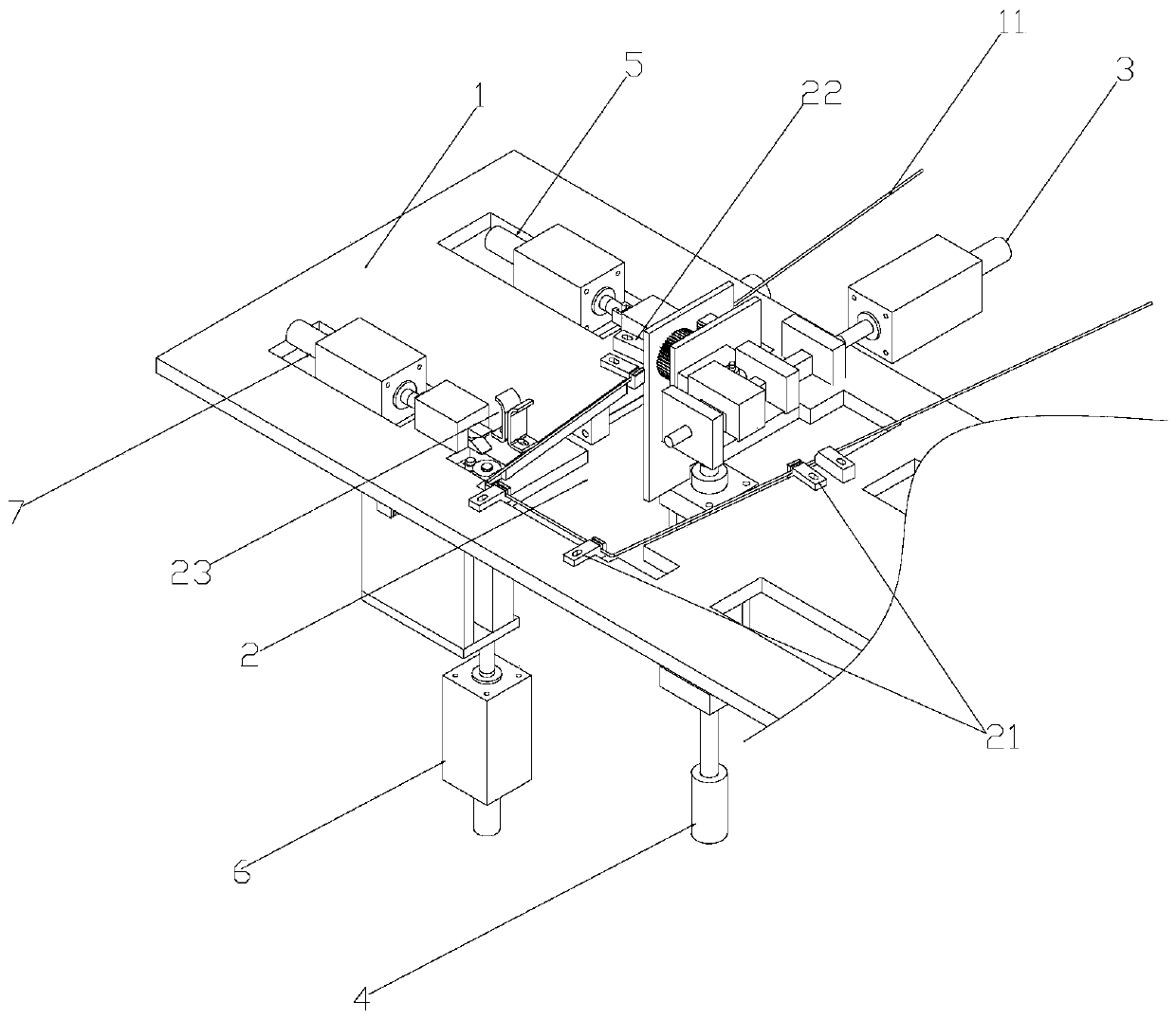

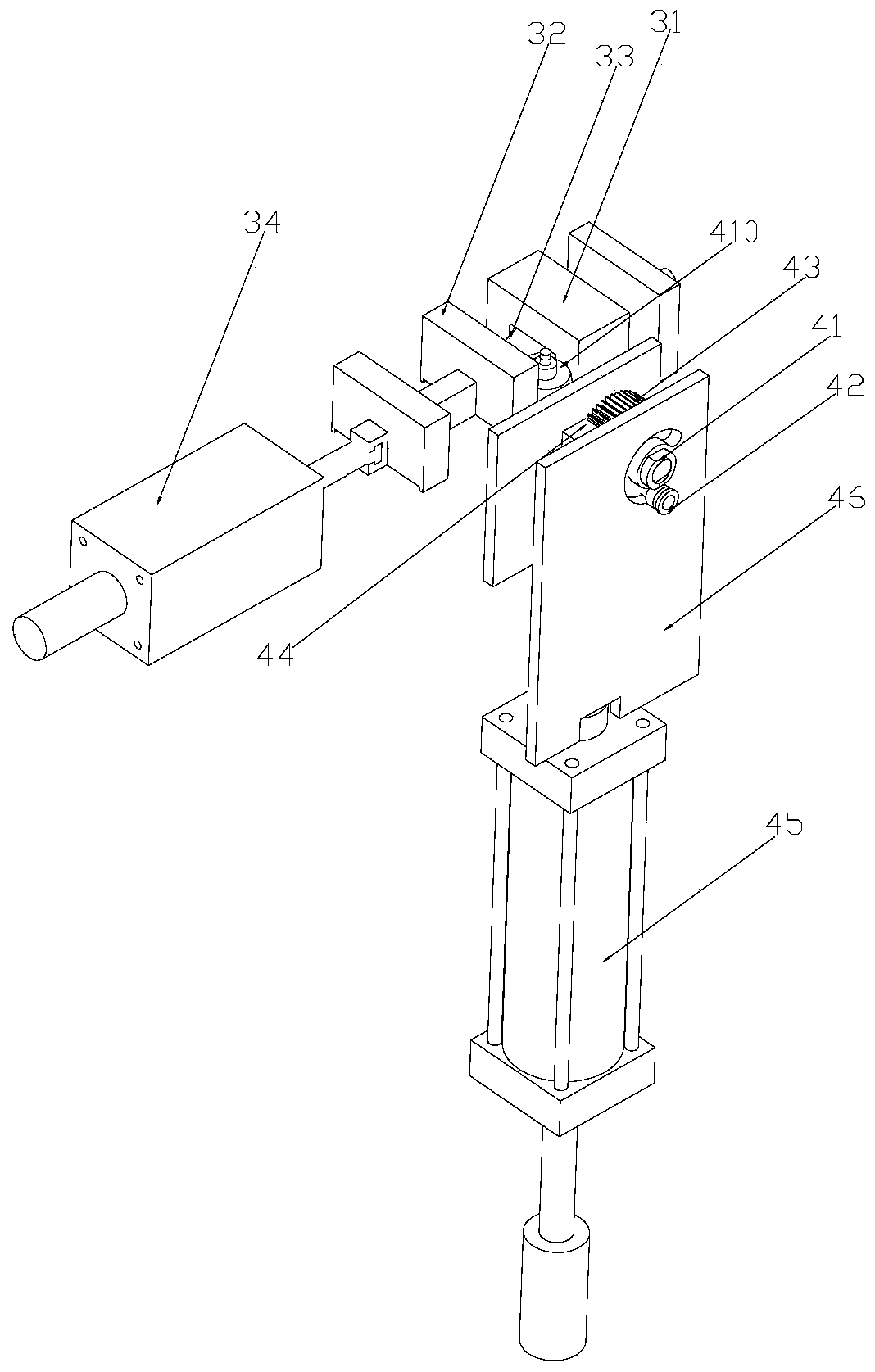

[0020] Such as Figure 1-Figure 4 As shown, the fully automatic two-dimensional wire bending forming machine according to the present invention includes a machine panel 1, a hollow part 2 for placing a fence wire 11 is provided in the middle of the machine panel 1, the left and right sides of the hollow part 2 and the bottom There is a positioning hook 21 for placing the wire rod 11 on the side, and the middle part of the front side of the hollow part 2 is provided with a double-sided shaft extension device 3 that protrudes forward into the hollow part 2, and the machine panel 1 is double-sided. The shaft extension device 3 is symmetrically arranged on both sides of the central axis. The hollow parts 2 on both sides of the double-sided shaft extension device 3 are provided with a front bending device 4 for spatially folding the wire 11. The double-side shaft extension device 3 is used to drive the front bending device 4 to limit and fix the wire 11. The front bending device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com