Medium-long beam production system and medium-long beam production and manufacturing method

A technology of production system and manufacturing method, which is applied in the direction of manufacturing tools, beams, building structures, etc., can solve the problems of easily scratching the operator's body, poor consistency of medium and long beams, and low production efficiency, so as to improve production efficiency, The effect of reducing contact and improving the economic efficiency of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

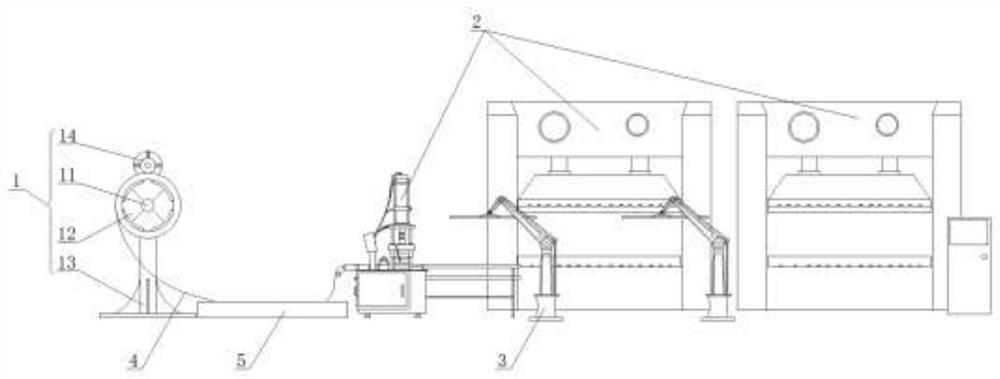

[0019] The present invention provides a medium and long beam production system, such as figure 1 As shown, it includes a feeder 1 and multiple processing equipment 2, the feeder 1 and multiple processing equipment 2 are arranged in sequence along the material flow direction, and a transfer machine 3 is arranged between any two adjacent processing equipment 2, and the feeder 1 includes an unwinding motor 11, an unwinding roller 12 is fixedly connected to the output shaft of the unwinding motor 11, and the feeder 1 is used to unwind and unroll the plate coil wound on the unwinding roller 12 into a slab 4, and the processing equipment 2 is used to process the slab 4, and the transfer machine 3 is used to transfer the slab 4 between two adjacent processing equipment 2. The control end of the unwinding motor 11, the control end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com