Wire forming machine of portal frame structure

A structure wire and gantry technology, which is applied in the field of gantry structure wire forming machines, can solve the problems of affecting the ductility and toughness of the wire, affecting the production efficiency, and being unable to form at one time, so as to improve production efficiency, convenient operation and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

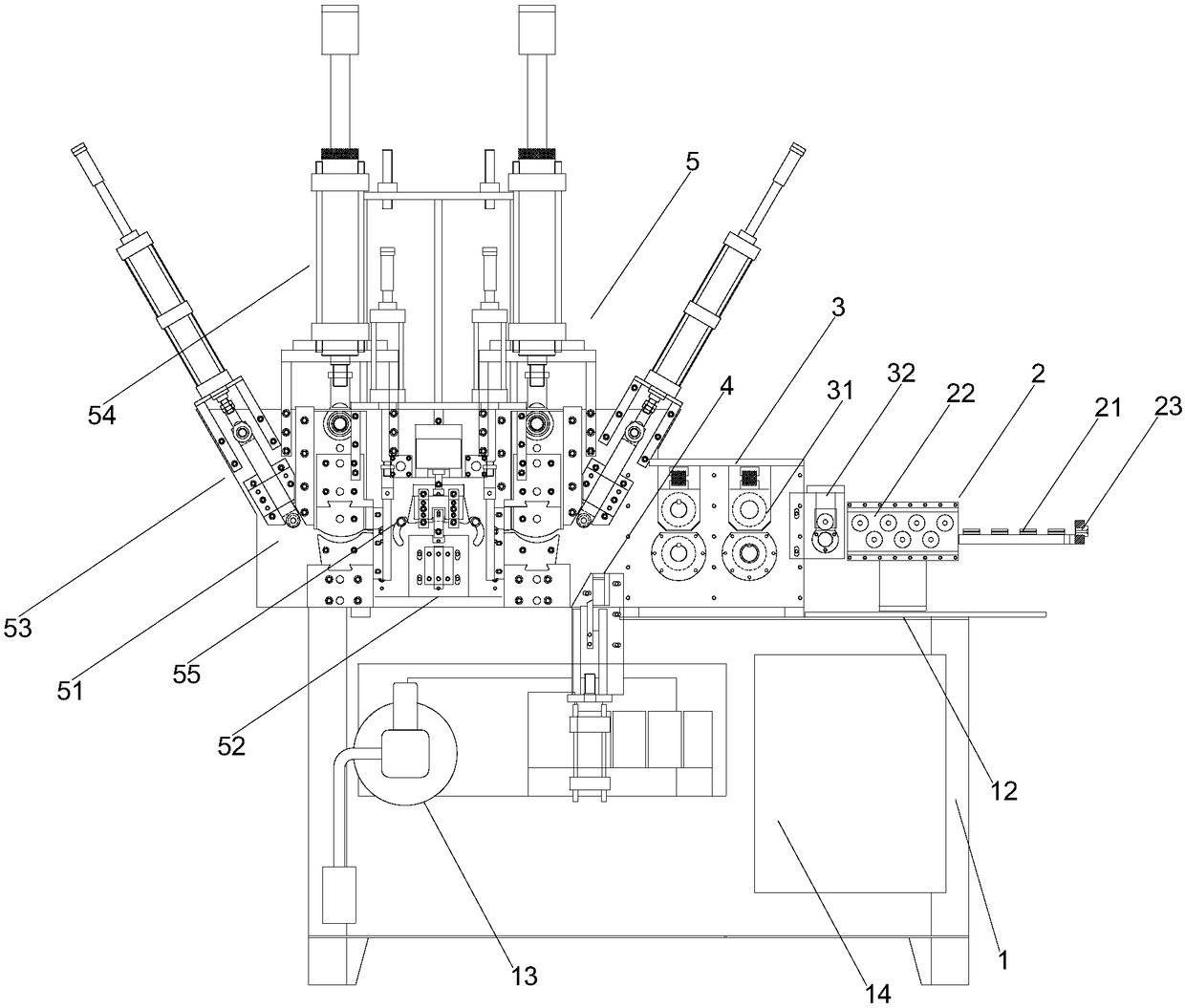

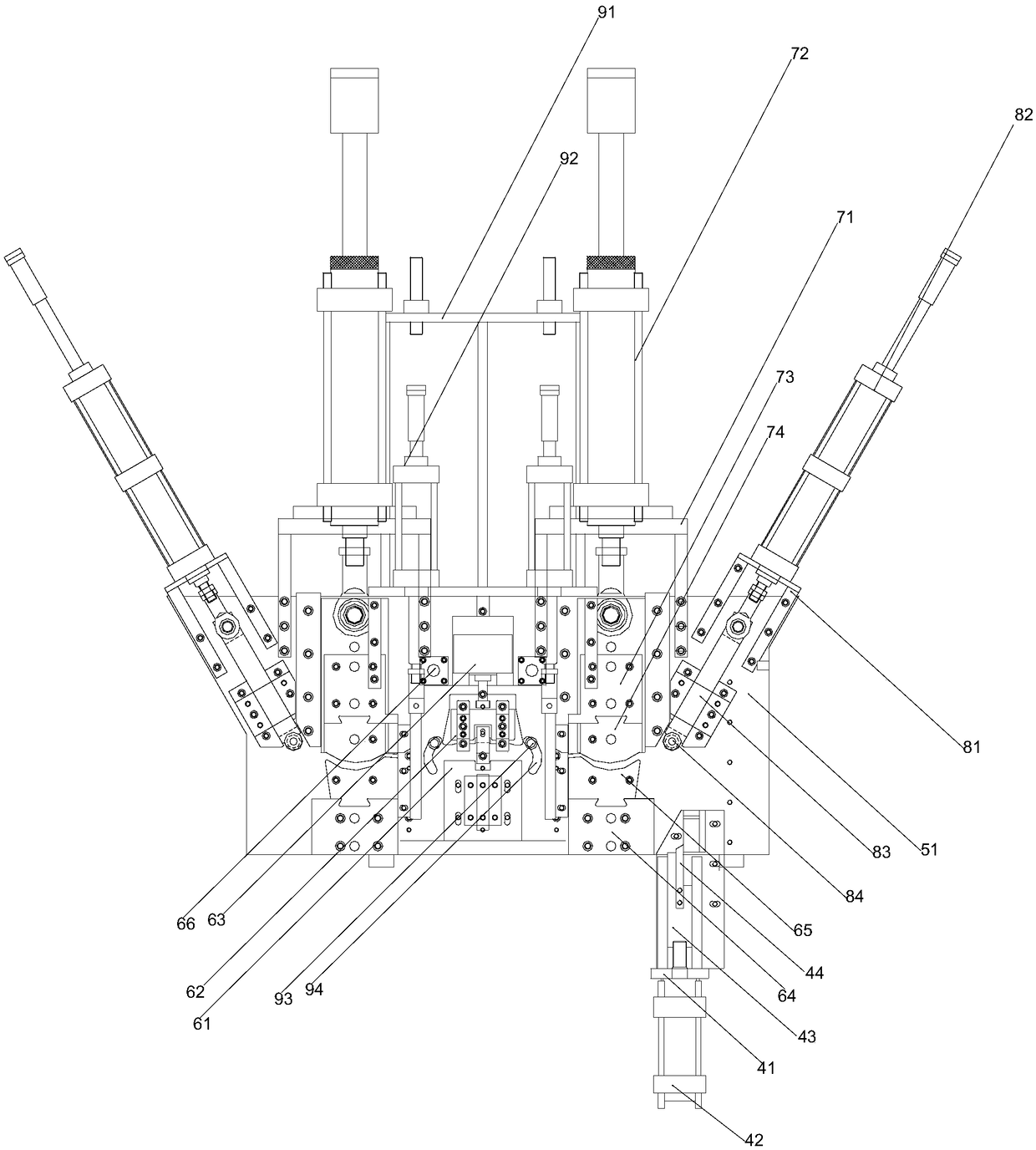

[0018] Such as Figure 1-Figure 2 As shown, the gantry structure line forming machine of the present invention includes a frame 1 and an operating table 12 installed on the frame 1, a driving part 13, and a control part 14. The side of the operating table 12 is provided with an opposite Reel-type wire straightening and flattening wire adjustment mechanism 2, the wire adjustment mechanism 2 includes a horizontal pressure roller set 21 and a longitudinal pressure roller set 22, the pressure of the horizontal pressure roller set 21 and the longitudinal pressure roller set 22 The wire openings are on the same horizontal plane, the wire inlet end of the horizontal pressure roller group 21 is provided with a wire nozzle 23, and the wire outlet end of the wire adjustment mechanism 2 is located on the operating table 12, and a wire wire mechanism 3 for conveying wire rods is installed. The above-mentioned wire mechanism 3 is installed on the main board between the rolling mechanism 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com