Waste heat recovery system of water injection screw air compressor

A technology of waste heat recovery system and air compressor, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of not meeting energy saving requirements, failure to effectively use heat energy, and waste, so as to ensure high efficiency and stability performance, avoiding excessive oil temperature, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

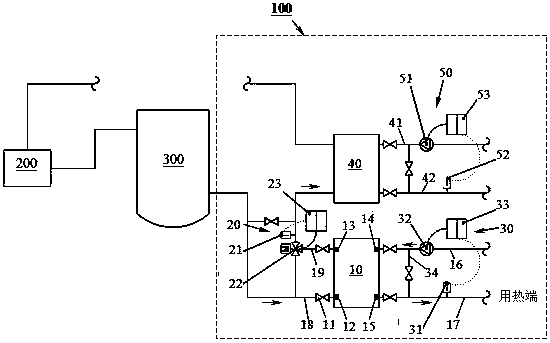

[0011] see figure 1 As shown, the present invention provides a water-cooled oil-injected screw air compressor waste heat recovery system 100, which is connected to a water-cooled oil-injected screw air compressor 200, and the water-cooled oil-injected screw air compressor 200 is also connected to an oil-gas separation cylinder 300 connections. The waste heat recovery system 100 includes a heat exchanger 10, an oil temperature control system 20 connected to the heat exchanger 10, a constant temperature water supply system 30, an oil cooler 40 connected to the oil temperature control system 20, and an oil cooler 40 connected to the oil temperature control system 20. The cooling water control system 50 to which the cooler 40 is connected.

[0012] The heat exchanger 10 is a heat exchanger, and its two sides are respectively connected with oil delivery pipes and water delivery pipes, and valves 11 are provided on the oil delivery pipes and water delivery pipes. The heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com