Automatic feeding and discharging method for welding wire spool

A technology of automatic loading and unloading and I-shaped wheels, which is applied in the direction of conveyor control devices, conveyors, mechanical conveyors, etc., can solve the problems of time-consuming, laborious, heavy welding wire I-shaped wheels, etc., to save labor costs and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

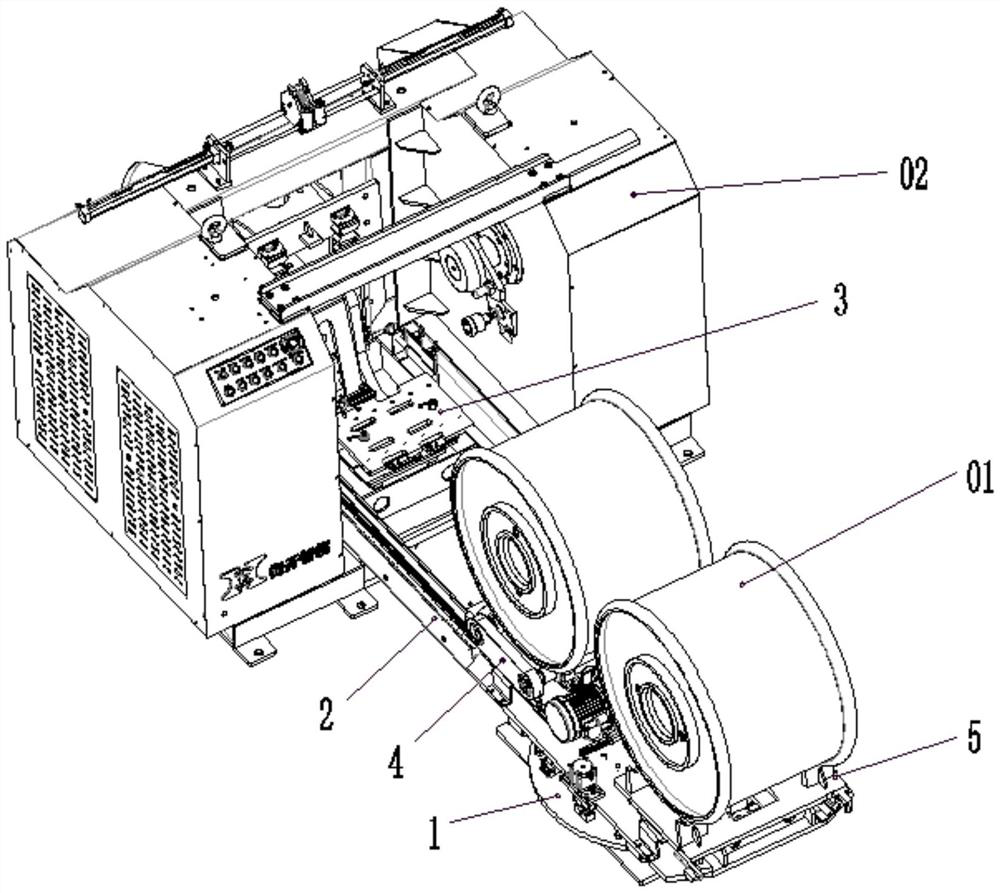

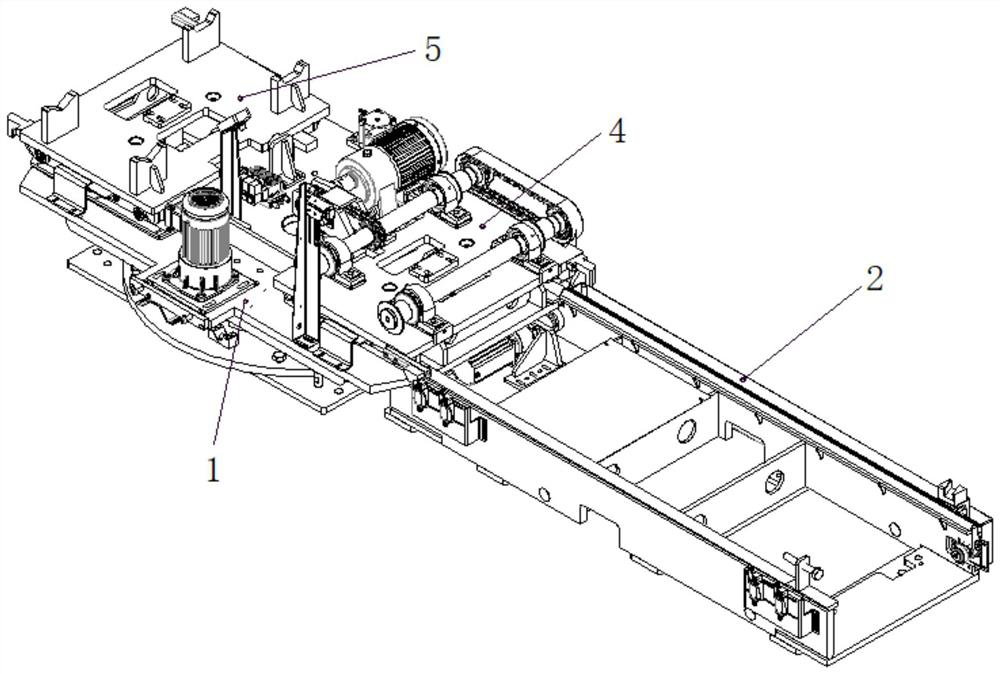

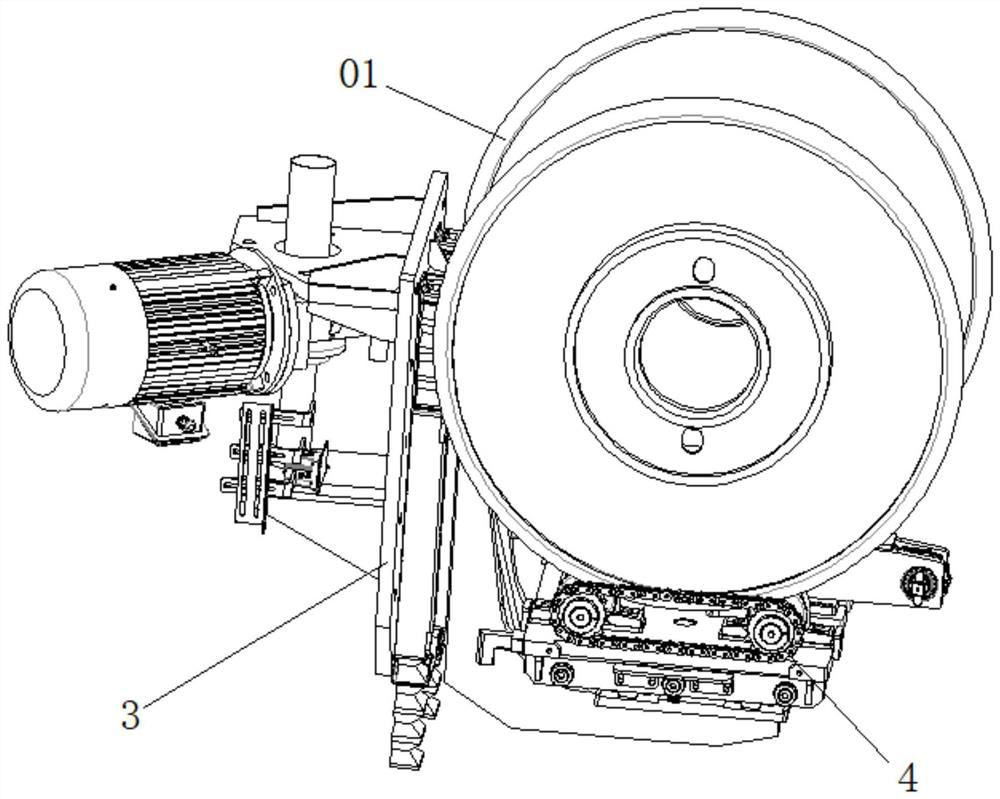

[0051] A method for automatic loading and unloading of welding wire spools. The automatic loading and unloading method of welding wire spools adopts an automatic loading and unloading device for welding wire spools. The automatic loading and unloading equipment for welding wire spools includes a double-station rotary platform 1. Linear transplanting platform 2, lifting mechanism 3 and feeding tray 4; both ends of linear transplanting platform 2 are respectively connected to double-station rotary platform 1 and lifting mechanism 3, and lifting mechanism 3 is fixedly installed on welding wire pay-off unit 02 On the top, the loading tray 4 moves above the double-station rotary platform 1, the linear transplanting platform 2 and the lifting mechanism 3; the loading tray 4 is used to carry the welding wire I-shaped wheel 01;

[0052] The double-station rotary platform 1 includes a rotary platform base 11, a slewing support bearing 12 and a rotary platform panel 13;

[0053] The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com