Mounting method and mounting tool for ship side large window

An installation method and tooling technology, applied in the direction of manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve problems such as low efficiency, easy to cause work injuries, easy damage, etc., achieve high work efficiency, improve work efficiency, and stability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

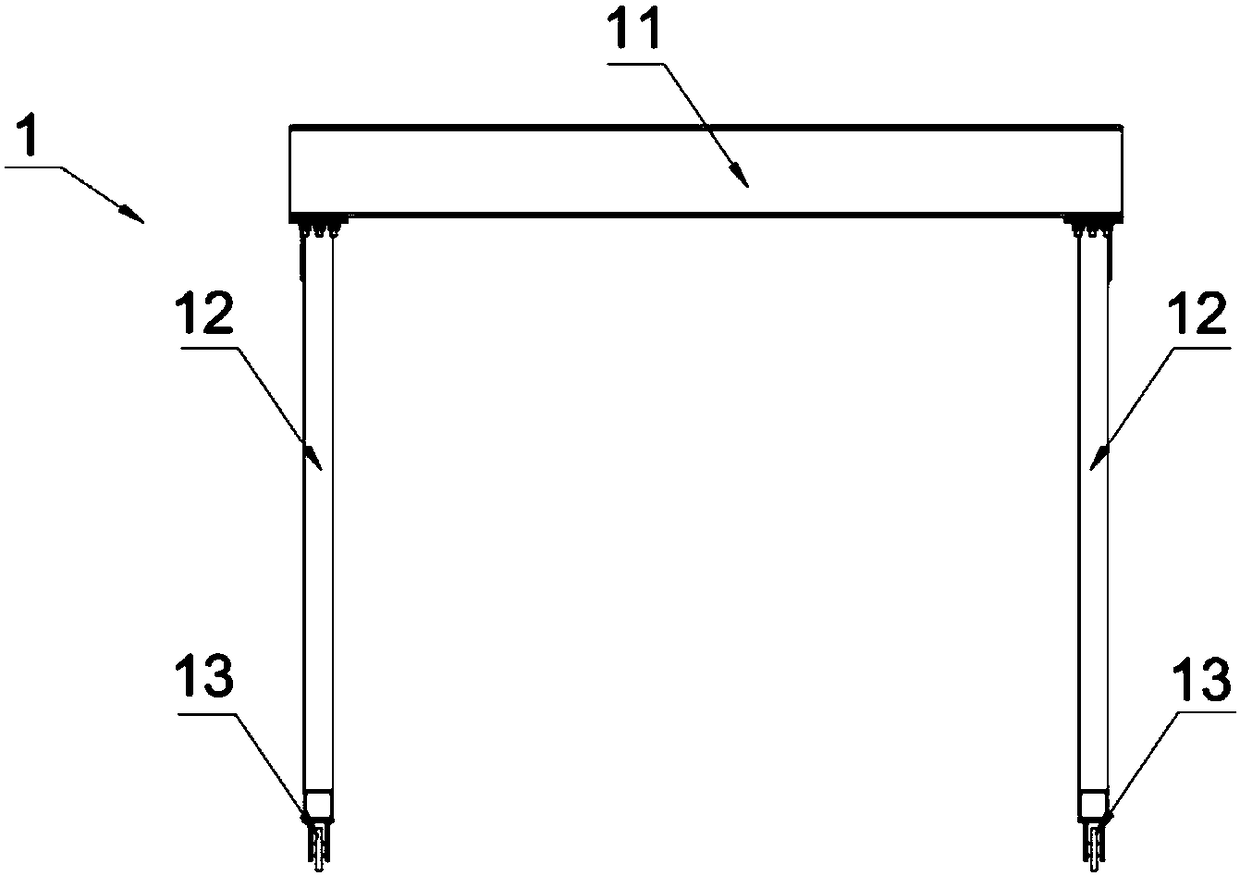

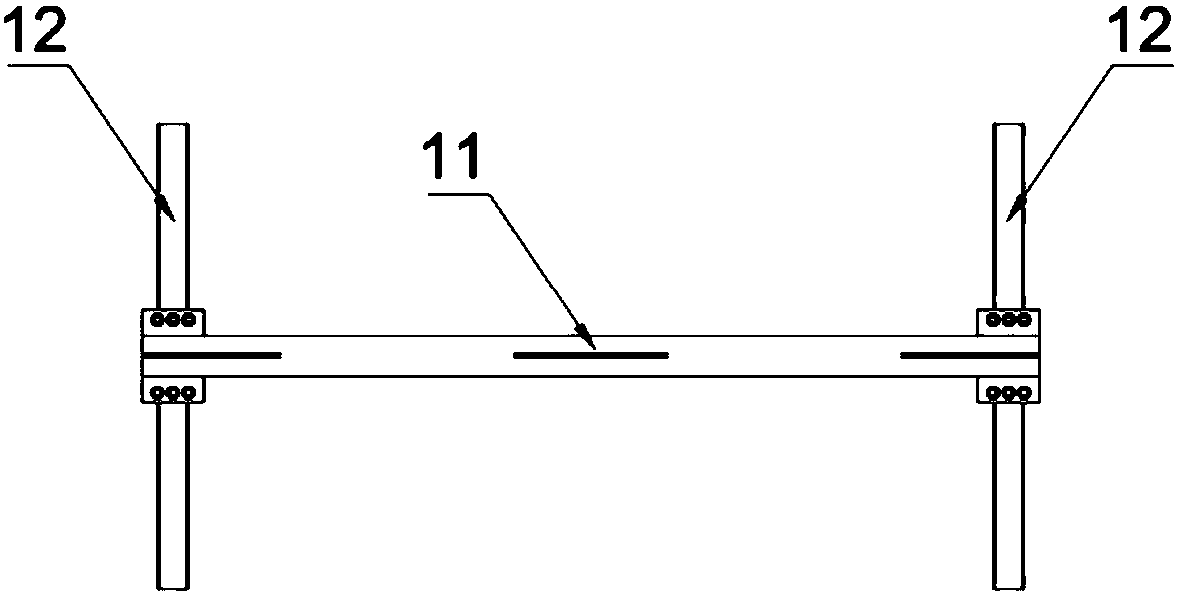

[0048] Embodiment 1 provides a kind of installation method that is used for ship side large window, such as Figure 5 shown, including the following steps:

[0049] S11. Lift the large window with a lifting tool and move it to the position of the window installing tool.

[0050] When the large window is lifted by the lifting tool, the large window is placed vertically, the two sides of the top of the large window are fixed by wire ropes, the electric hoist is started, the large window is lifted, and the large window leaves the ground. In the process of hoisting the large window, the large window is vertically arranged, and the large window moves upwards along the vertical direction to facilitate the movement of the large window.

[0051] S12. Transfer the large window to the window installation tool.

[0052]Transfer the large window to the window installation tool, place the large window on the base and one side of the support component, and place a counterweight structure ...

Embodiment 2

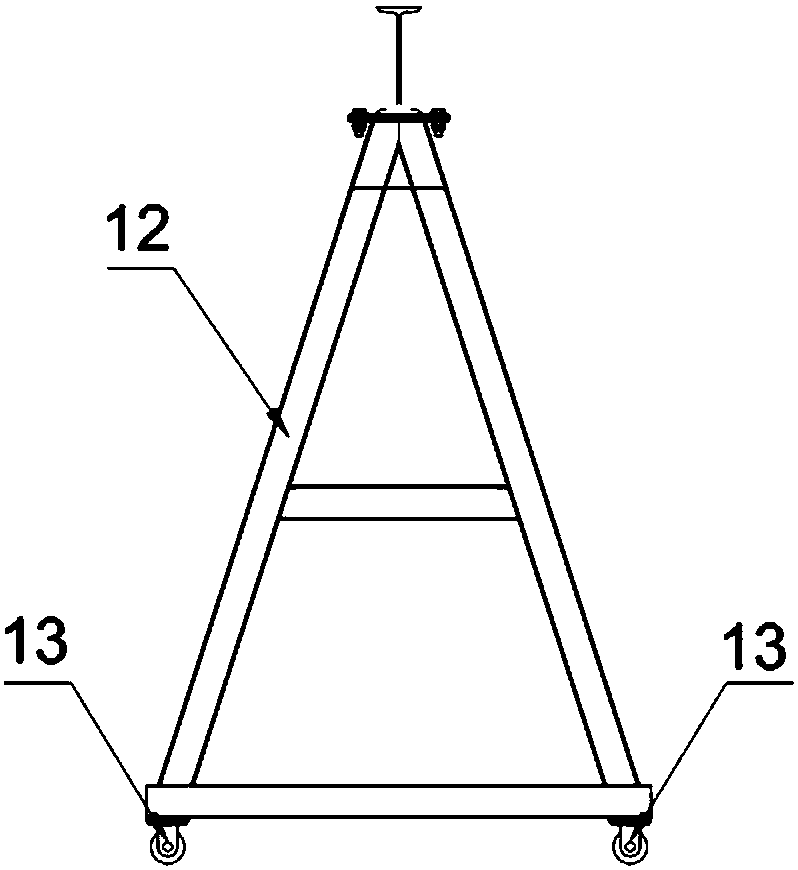

[0059] In this embodiment, a kind of installation tool for large side windows of ships is provided. The difference between this embodiment and Embodiment 1 is that the structure of the window installation tool 2 is different, and the installation tool also includes a handling device (not shown in the figure) And adsorption device 29, can realize the automatic installation of large window.

[0060] Specifically, as Image 6 As shown, the supporting part 22 of the installation tool is slidably arranged on the base 21 along the first direction, the first direction is the direction perpendicular to the ship's side near or away from the ship's side, and the supporting part 22 is connected with the first driving mechanism (not shown in the figure), The first driving mechanism drives the support member 22 to move along the first direction. Further, a first slide rail 211 is provided on the base 21 , the first slide rail 211 extends along a first direction, and the support member 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com