Full-automatic wire rod double-end oblique angle cutting-off machine

A fully automatic cutting machine technology, applied in the field of wire processing equipment, can solve the problems of reduced stability, more man-hours, and different lengths of cutting materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

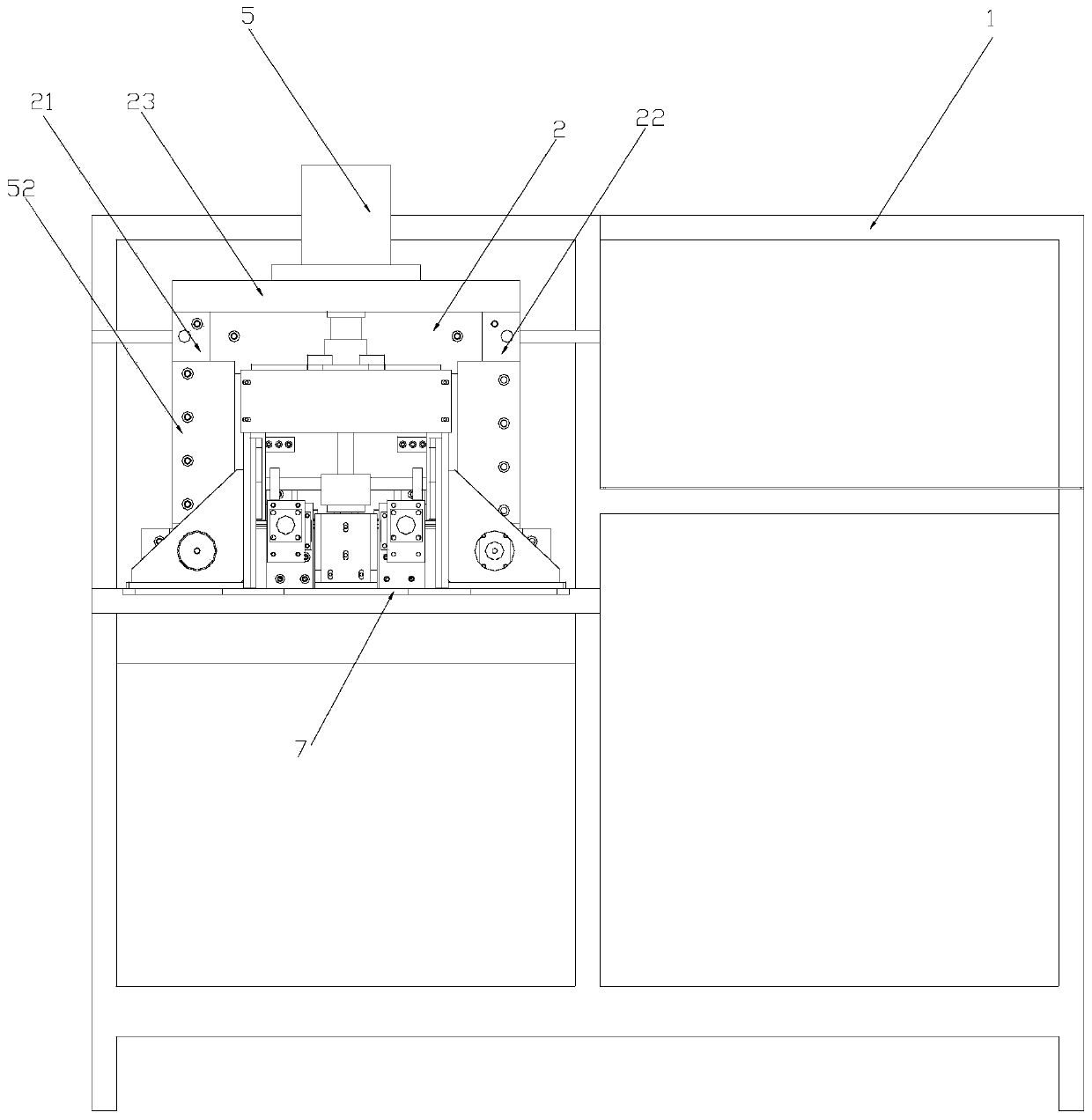

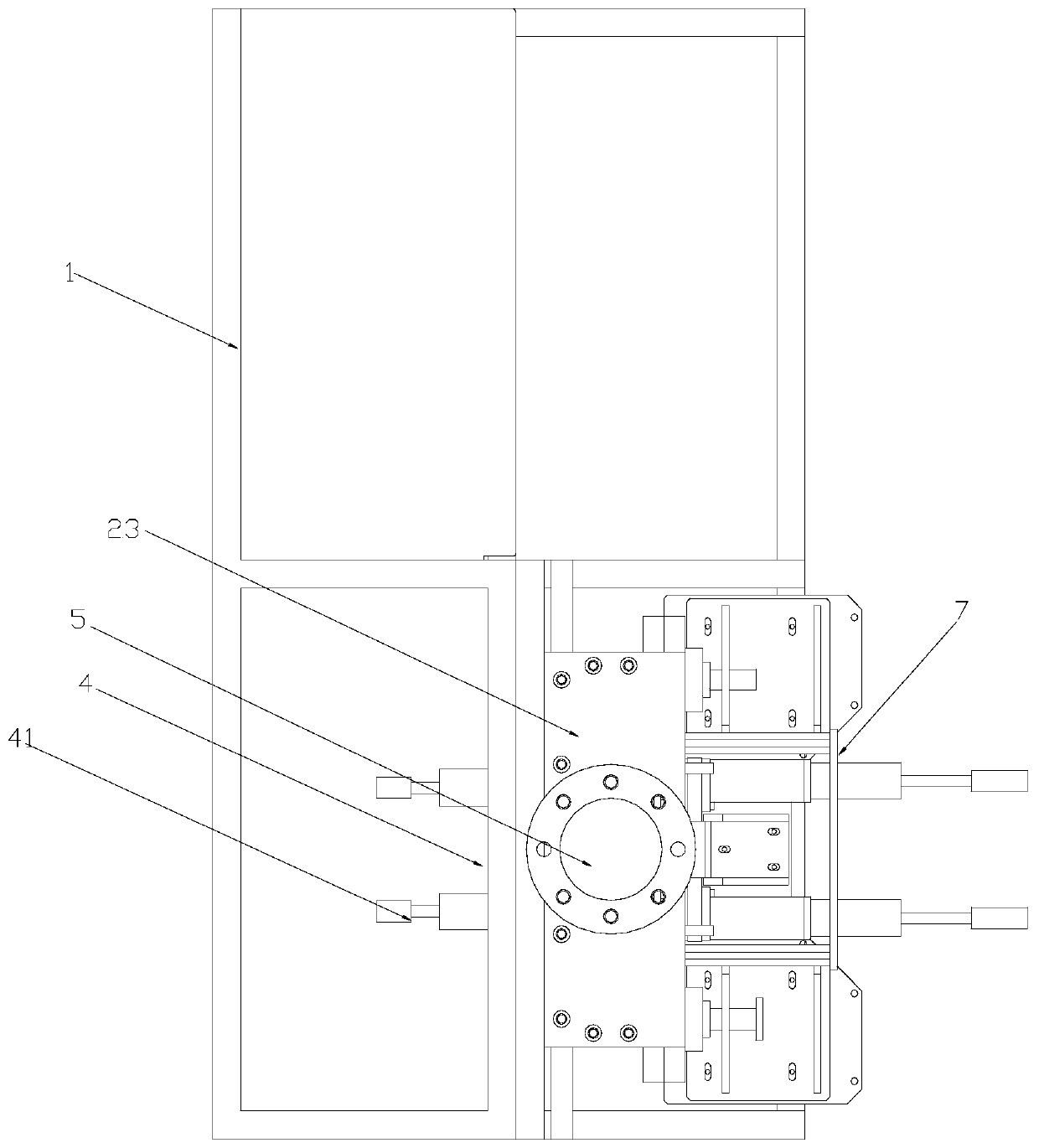

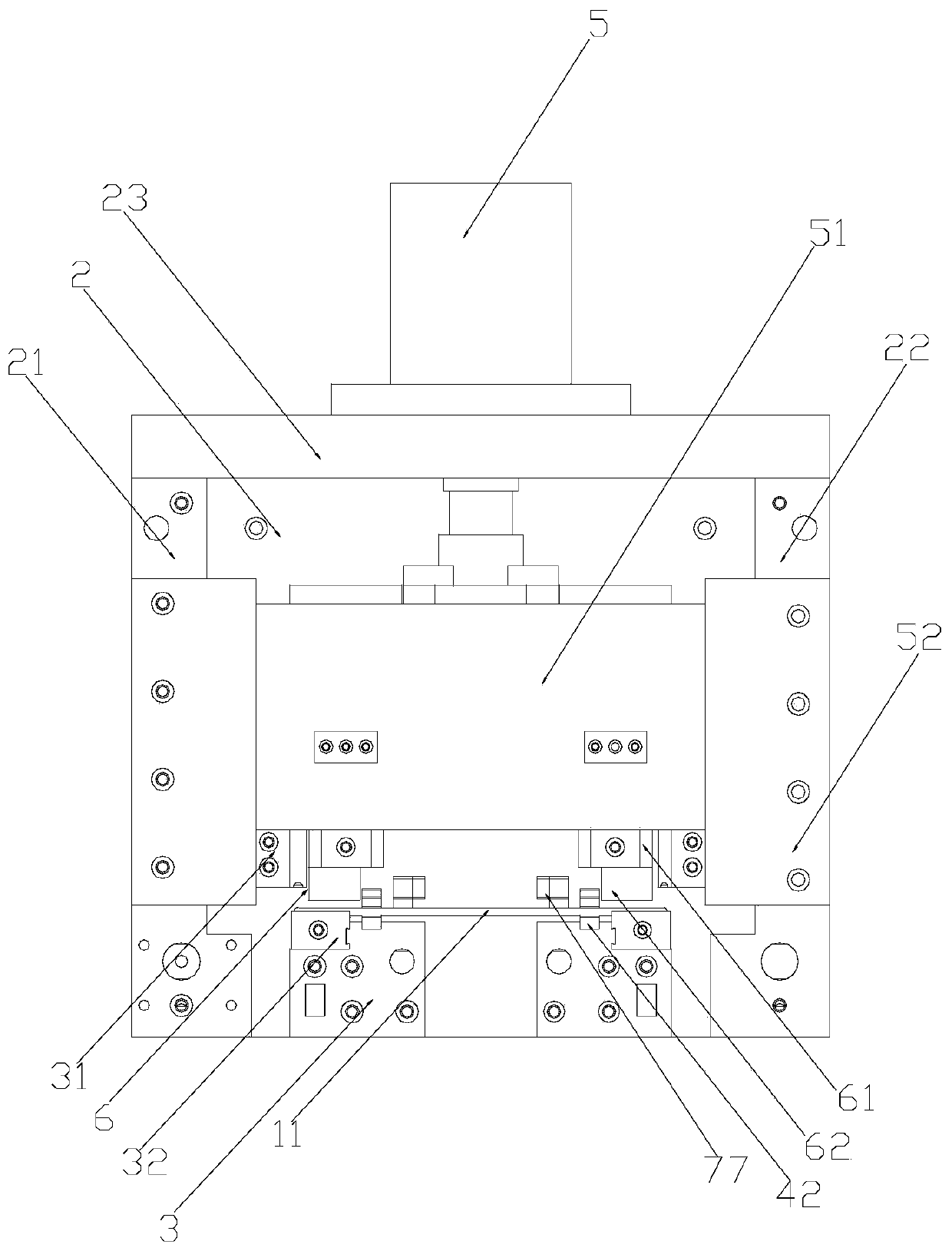

[0023] Such as Figure 1-Figure 3 As shown, the fully automatic wire double-head bevel cutting machine of the present invention includes a frame 1 and a cutting machine vertical plate 2 vertically installed on the frame 1, and the front of the cutting machine vertical plate 2 is provided with left and right sides. Symmetrical left guide rail 21 and right guide rail 22, between described left guide rail 21 and right guide rail 22 is positioned at the front of cutting machine vertical plate 2 and is installed with the cut-off mold base 3 that places the diagonal bracing line 11 of processing, and described cutting machine The back of the vertical plate 2 is equipped with a pusher assembly 4 that pushes out the diagonal bracing line 11 on the cutting mold base 3, the left guide rail 21, the right guide rail 22 and the top of the cutting machine vertical plate 2 are equipped with a horizontally placed mounting plate 23, The installation plate 23 is provided with a cutting machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com