Rubber tube scrap edge unloading device

A rubber-plastic pipe and edge trimming technology, applied in metal processing and other directions, can solve the problems of work-related injury risks, time-consuming and labor-intensive, and low work efficiency, and achieve the effects of reducing work-related injury risks, reducing labor intensity, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

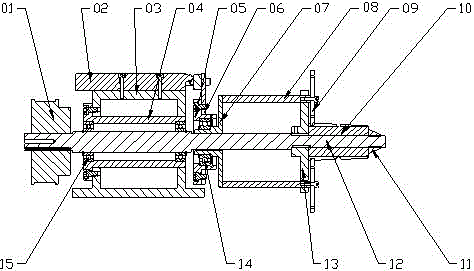

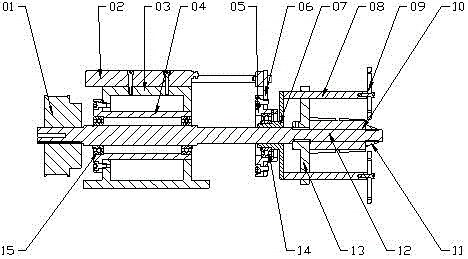

[0035] In order to describe in detail the technical content, structural features, goals and effects achieved by the device for removing trimmings from rubber and plastic pipes of the present invention, the following will be further described in conjunction with the embodiments and accompanying drawings.

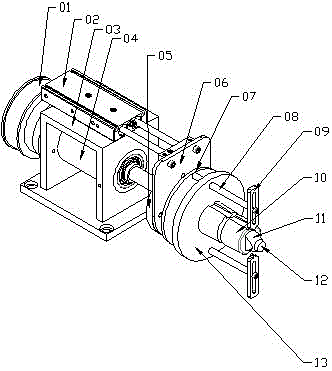

[0036] like Figure 1 to Figure 4 As shown, an embodiment of a rubber and plastic pipe trimming removal device is disclosed. The present invention includes a synchronous wheel 01, a double-axis cylinder 02, a seat frame 03, a bearing seat 04, a mobile bearing seat 05, a push plate 06, and a push plate 07 , push rod 08, push finger 09, support mold 10, lock nut 11, driving shaft 12, support plate 13, bearing A14 and bearing B15, because the control system selects commercially available PLC controller standard components and does not need to be shown in the accompanying drawings It shows that the synchronous wheel 01 is set on one end of the driving shaft 12 and fixed with a ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com