Inner rotor permanent magnet synchronous traction machine

A technology of synchronous traction machine and inner rotor, applied in the field of traction machine, can solve the problem of poor heat dissipation effect of stator coil package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

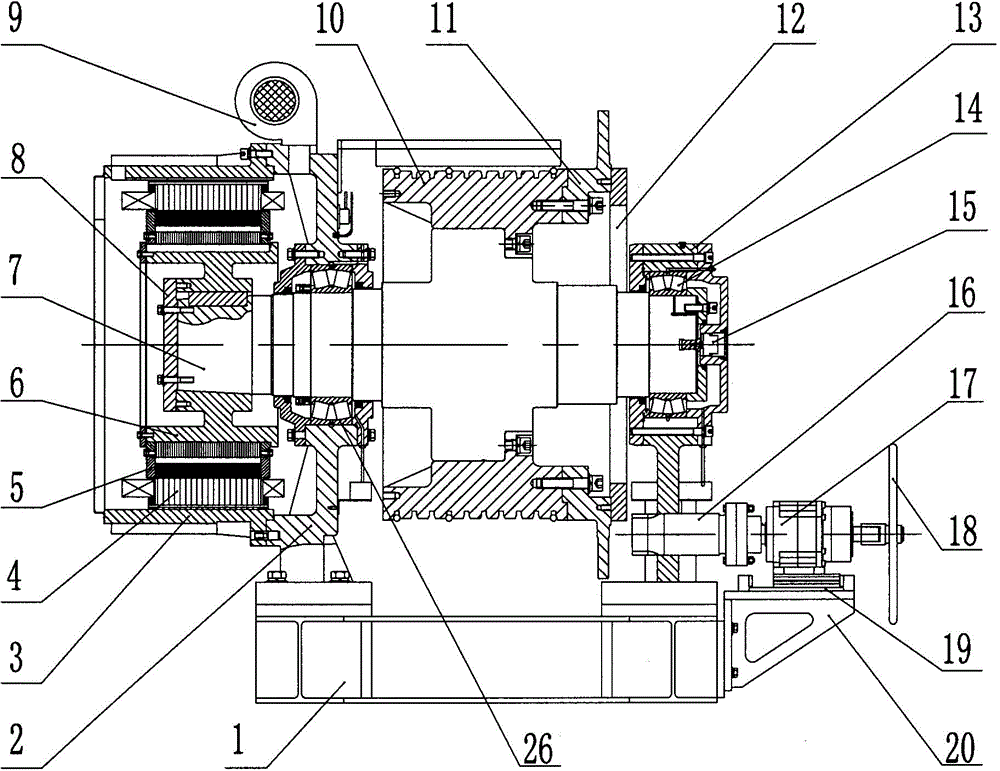

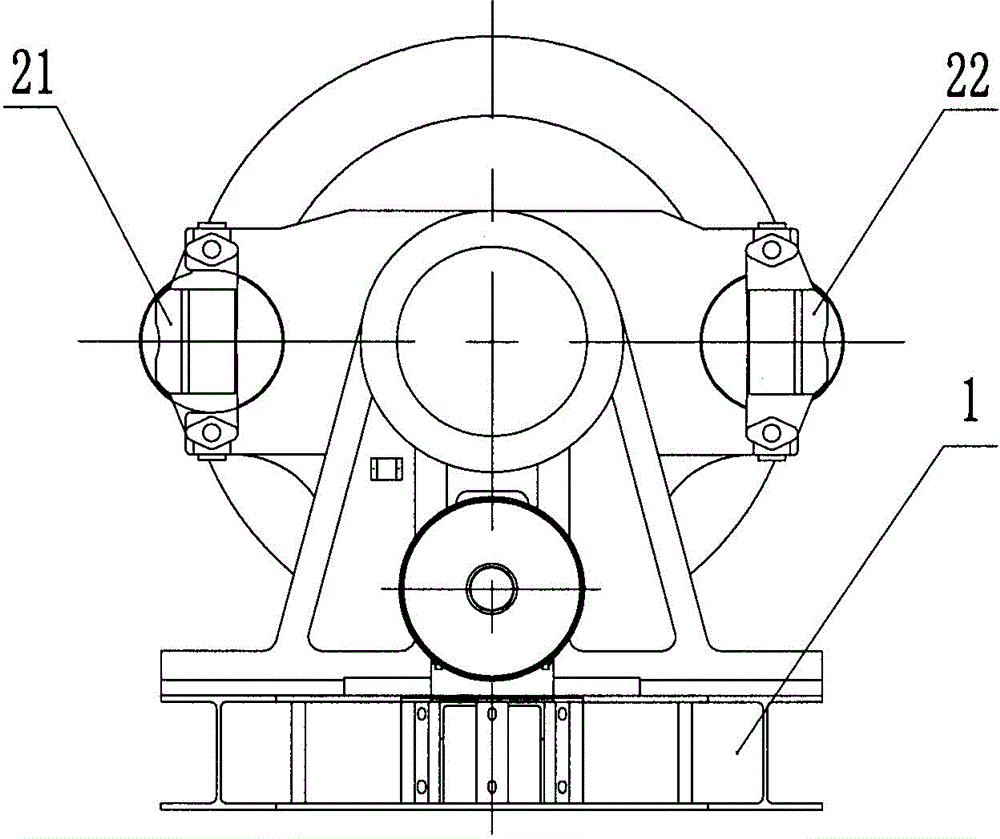

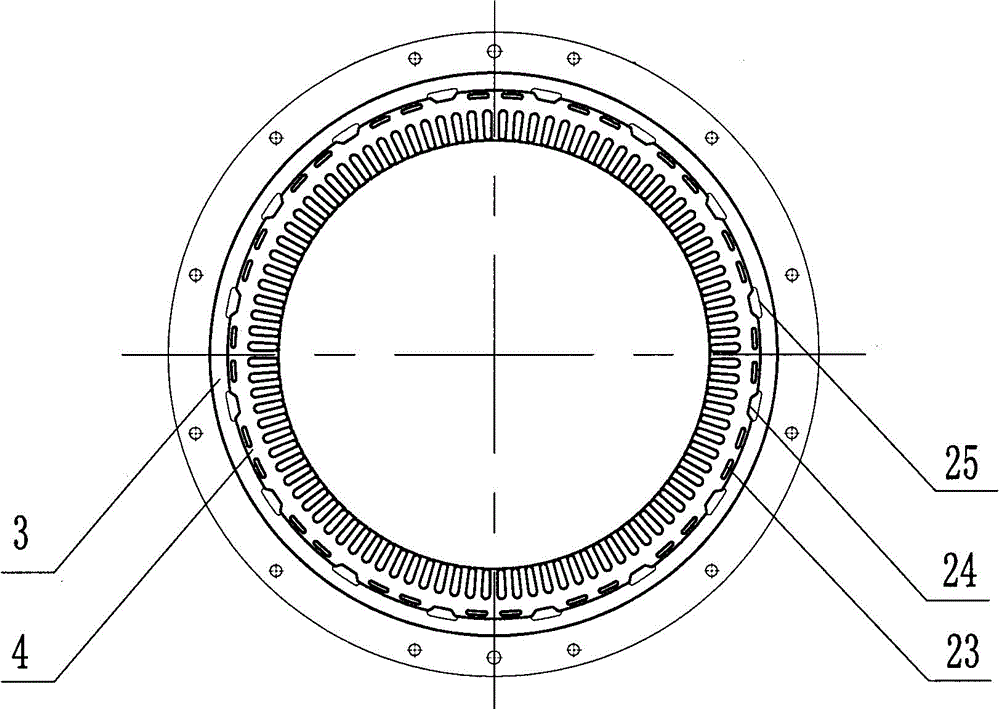

[0014] according to Figure 1~3 The specific structure of the present invention will be described in detail. The inner rotor permanent magnet synchronous traction machine is mainly designed to solve the technical problems of the existing ultra-high-speed and large-load traction machines, such as the poor heat dissipation effect of the stator wire package, and the inability to meet the needs of manual cranking of high-torque traction machines. . The original interference-connected rotor sleeve and the main shaft are set into an integrated structure, that is, the integrated main shaft is used as the rotor. It includes a frame 1, a frame 2 assembled on the frame 1 and a front support 13, a built-in stator wire package 4 assembled on the frame 2 and a casing 3 of the rotor core 5. The sub-bearings 14, 26 are assembled on the front support 13 and the main shaft 7 on the machine base 2, the traction sheave 10 and the encoder 15 assembled with the main shaft 7 are composed of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com