Gantry structure of portal crane

A portal-type crane and portal-seat technology, which is applied to the bottom support structure, lifting equipment braking device, load hanging components, etc., can solve the problems of inconvenient maintenance, poor stability and reliability, etc., and achieve stable structure, high reliability, The effect of large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

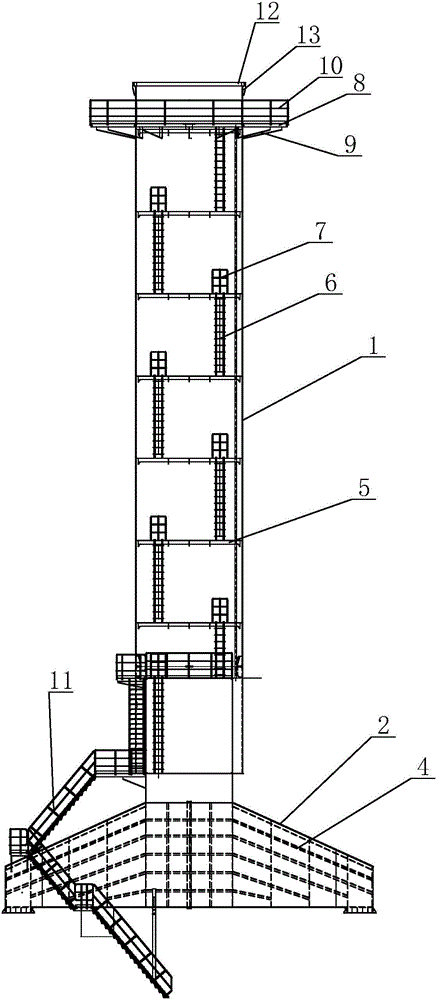

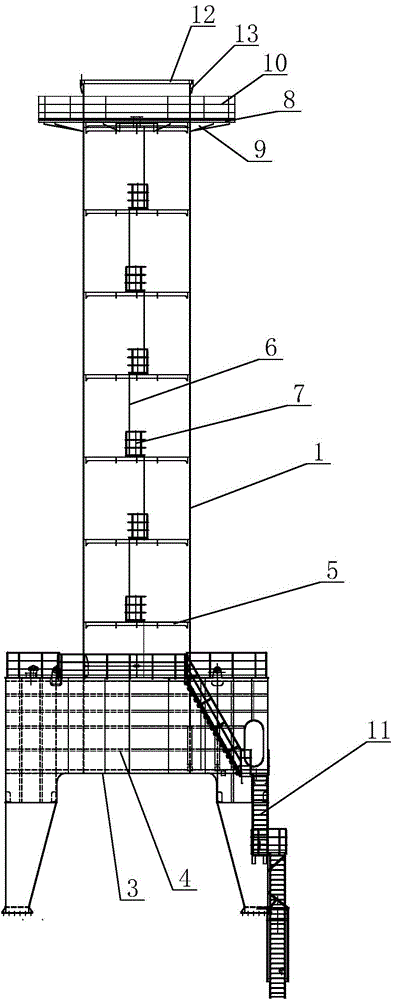

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0017] see figure 1 and figure 2 As shown, in this embodiment, a door frame structure of a portal type crane includes a door seat and a cylinder body 1, the door seat is welded by a door seat beam 2 and a door seat end beam 3, and the cylinder body 1 is fixed on the door seat beam 2, and several door seat reinforcing rib plates 4 are welded and fixed inside the door seat beam 2 and the door seat end beam 3. Inside the cylindrical body 1 are welded several pieces of cylindrical reinforcement ribs 5 at intervals along the height direction, and several cylindrical climbing ladders 6 are arranged outside the cylindrical body 1, and the several cylindrical climbing ladders 6 are staggered and fixed. Outside the cylinder 1, a connecting platform is provided between two adjacent cylinder climbing ladder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com