Soap making machine and soap making method

A soap making machine and lye technology, applied in mixing/kneading soap and other directions, can solve the problems of long stirring time, loss of nutrients, poor stirring effect, etc., to improve quality and stability, and improve the success rate and quality of production Stability, speed up effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with specific embodiment and accompanying drawing, the present invention is described in detail:

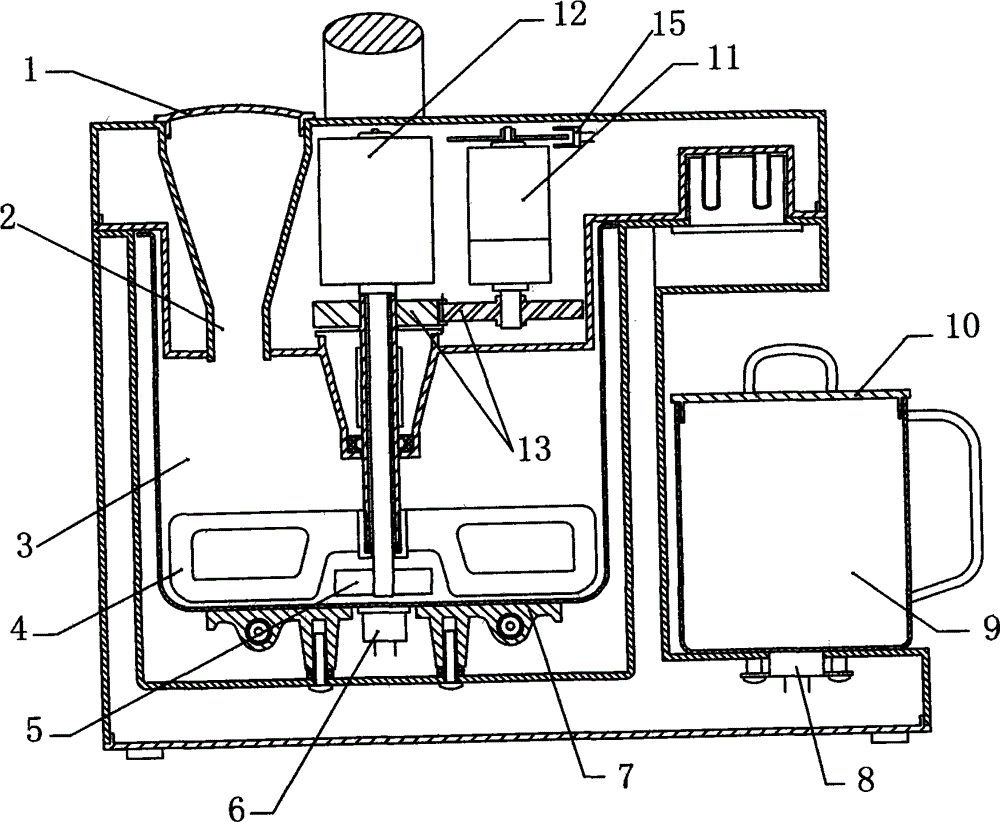

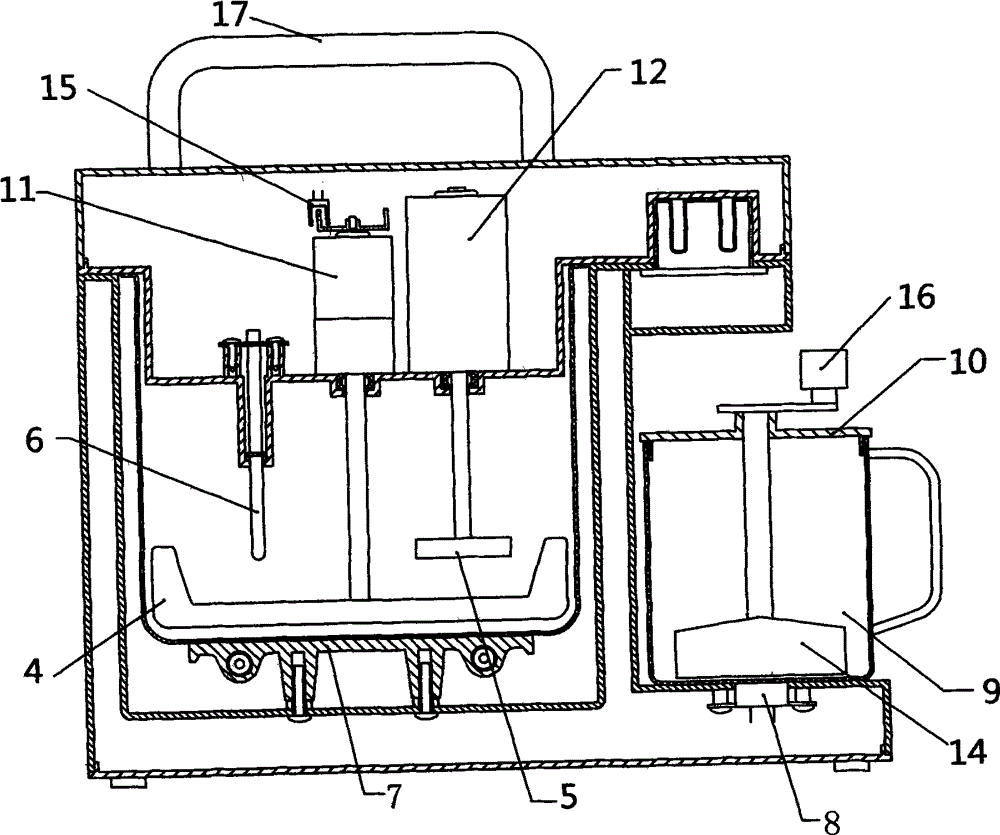

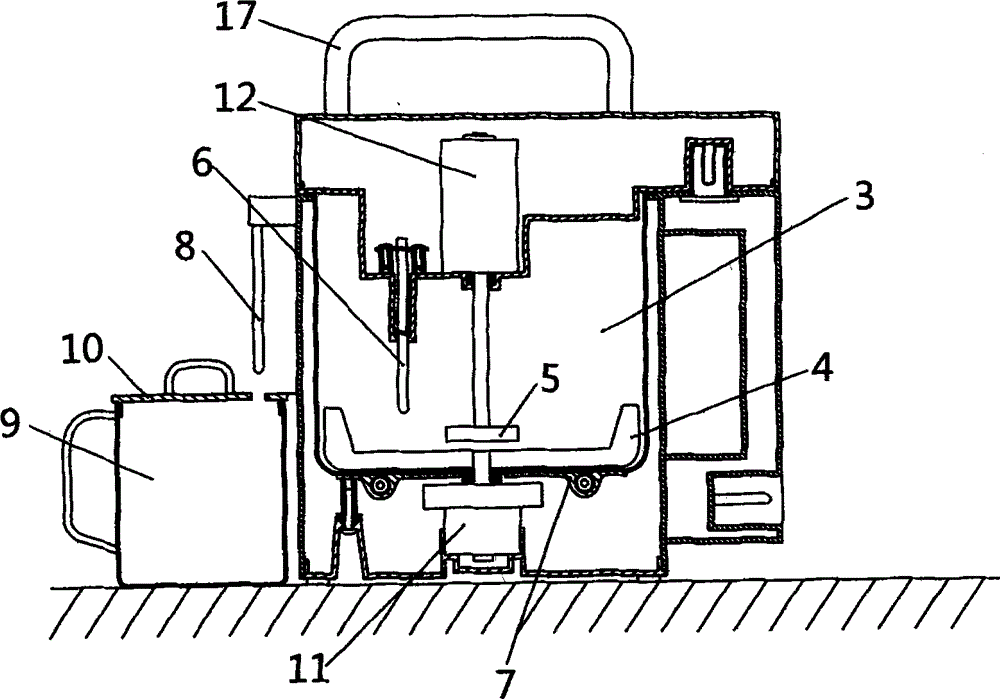

[0052] figure 1 It is a schematic structural diagram of a soap making machine provided in Embodiment 1 of the present invention, including: an lye treatment system, a stirring system, a heating system, and an electric control system; the lye treatment device is used for dissolving alkali blocks and detecting the temperature, the lye after dissolving and when the temperature reaches the first set temperature is output to the stirring system; 2. Mix and stir with the lye at the set temperature, the difference between the first set temperature and the second set temperature is less than or equal to 15°C; The mixture of materials such as lye is heated, and the temperature of the material in the stirring container is detected; the electric control system is used to control the process of the lye treatment system, the stirring system, and the heating system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com