Sealing joint for transfer between cable and signal cable and manufacturing method thereof

A technology of sealing joints and adapters, which is applied in the direction of cable joints, cable installation, equipment for connecting/terminating cables, etc., and can solve problems such as safety accidents, line transmission failures, and damaged cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

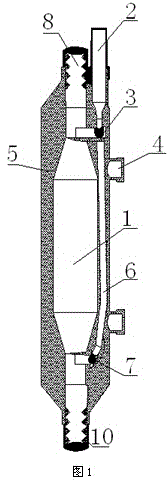

[0027] A sealing joint for connecting cables and signal cables, such as figure 1 As shown, it includes a stress tube 1, a coaxial cable joint 2, a waterproof system 5, and an electrode. The cross section at both ends of the stress tube 1 is smaller than the cross section in the middle, and a first protective layer is arranged around the stress tube 1. In the first A coaxial cable connector 2 is provided on the outside of the protective layer and at one end of the stress tube 1. The coaxial cable connector 2 and the stress tube 1 are connected by electrodes. The waterproof system 5 is sleeved on the stress tube 1 and the coaxial cable. The cable joint 5 also includes an extension pipe 8 , the inner wall of which is provided with an internal thread 10 , and the extension pipe 8 is connected to both ends of the stress pipe 1 .

[0028] When in use, since the inner wall of the extension tube 8 is provided with an internal thread 10, when the cable is connected to the stress tube, ...

Embodiment 2

[0030] This embodiment is further optimized on the basis of the above embodiments, and further, in order to better realize the present invention, as figure 1 As shown, it includes a stress tube 1, a coaxial cable joint 2, a waterproof system 5, and an electrode. The cross section at both ends of the stress tube 1 is smaller than the cross section in the middle, and a first protective layer is arranged around the stress tube 1. In the first A coaxial cable connector 2 is provided on the outside of the protective layer and at one end of the stress tube 1. The coaxial cable connector 2 and the stress tube 1 are connected by electrodes. The waterproof system 5 is sleeved on the stress tube 1 and the coaxial cable. On the cable joint 5; also includes an extension tube 8, the inner wall of the extension tube 8 is provided with an internal thread 10, and the extension tube 8 is connected to both ends of the stress tube 1; it also includes a test hole 4, and the opening of the test hol...

Embodiment 3

[0032] This embodiment is further optimized on the basis of embodiment 1, as figure 1 As shown, further, in order to better realize the present invention, it includes a stress tube 1, a coaxial cable joint 2, a waterproof system 5, and an electrode. There is a first protective layer, and a coaxial cable connector 2 is arranged on the outside of the first protective layer and at one end of the stress tube 1, and the coaxial cable connector 2 and the stress tube 1 are connected by electrodes, and the waterproof The system 5 is sleeved on the stress tube 1 and the coaxial cable joint 5; it also includes an extension tube 8, the inner wall of the extension tube 8 is provided with internal threads 10, the extension tube 8 is connected to both ends of the stress tube 1, and the electrodes Including a first electrode 3 and a second electrode 7, the first electrode is located at the side of the coaxial cable joint 2 and connected to the stress tube 1, the second electrode 7 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com