Patents

Literature

30results about How to "Affect electrical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radio frequency coaxial electric coupler with quick-locking device

ActiveCN103094782ASimple structureQuick assemblySecuring/insulating coupling contact membersCoupling contact membersElectrical conductorElectrical connection

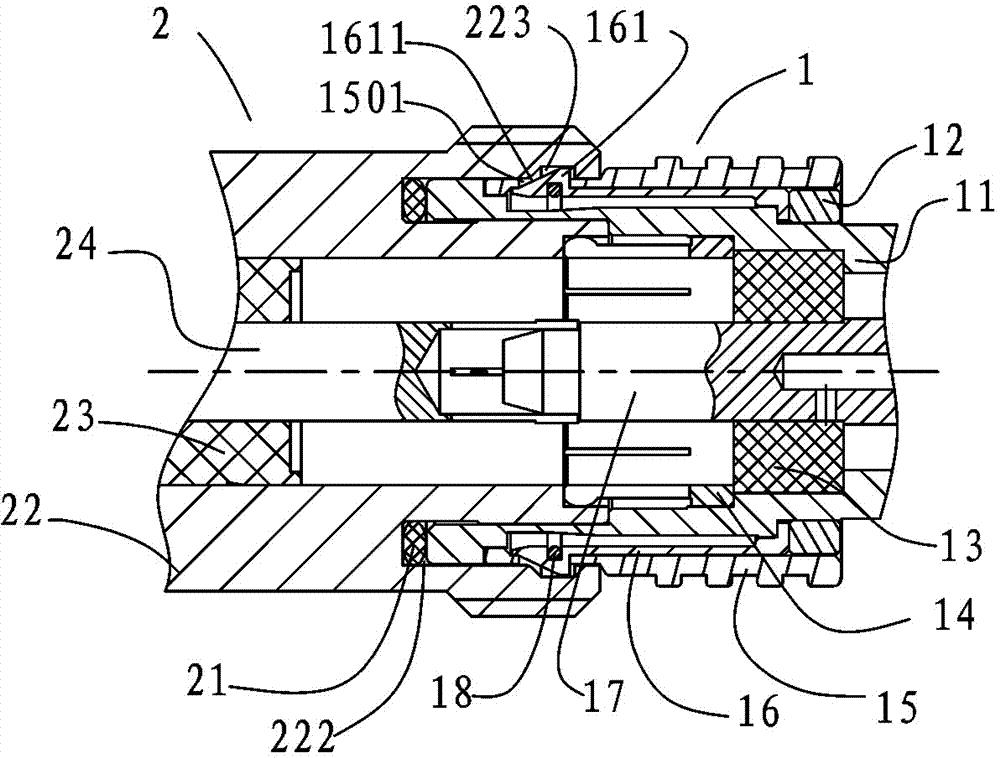

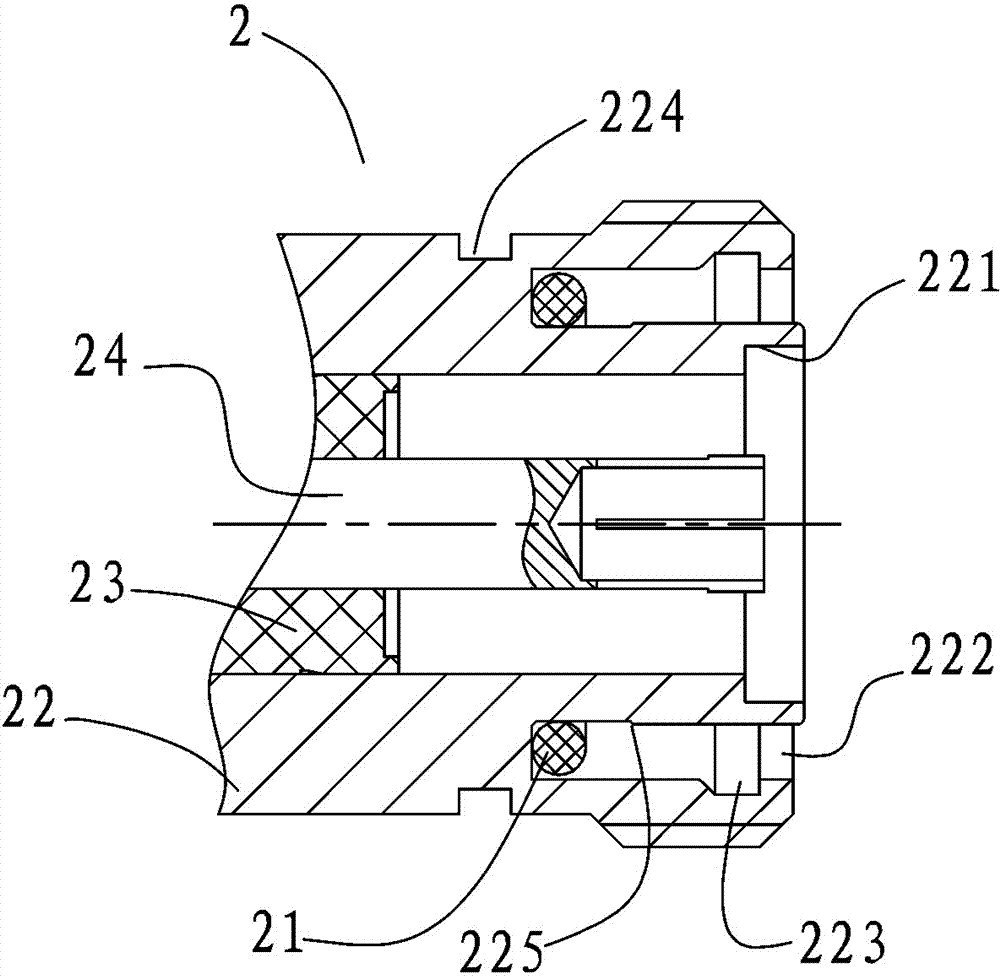

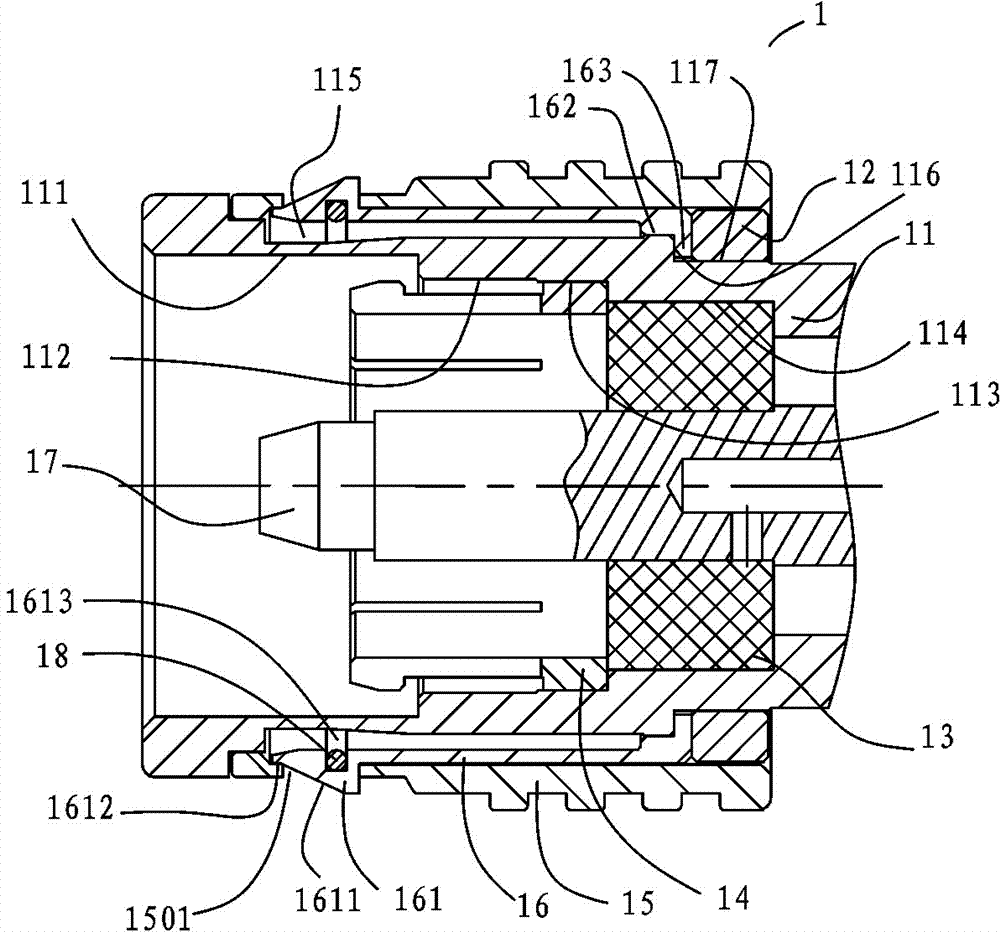

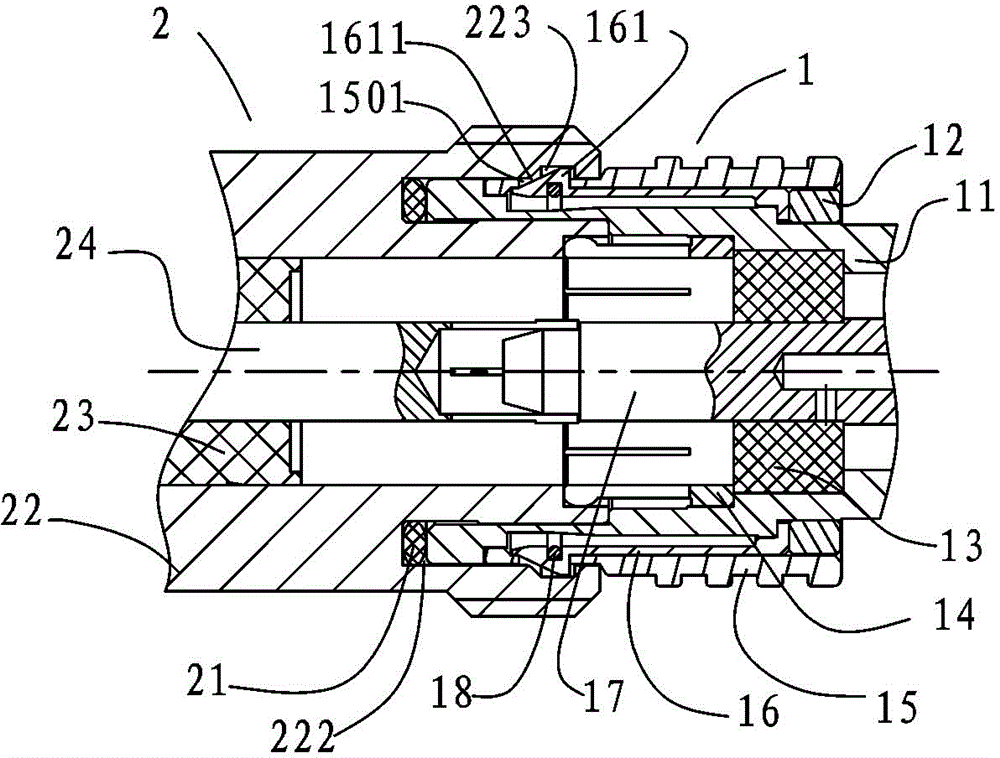

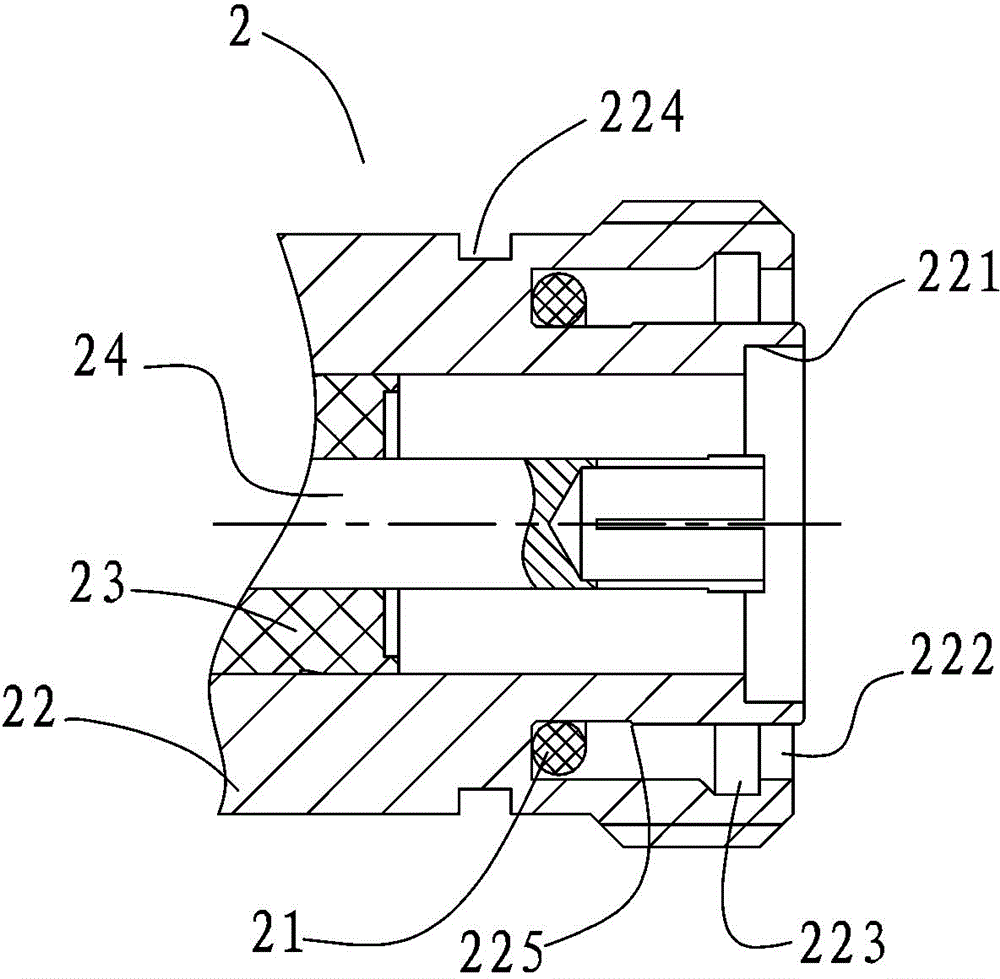

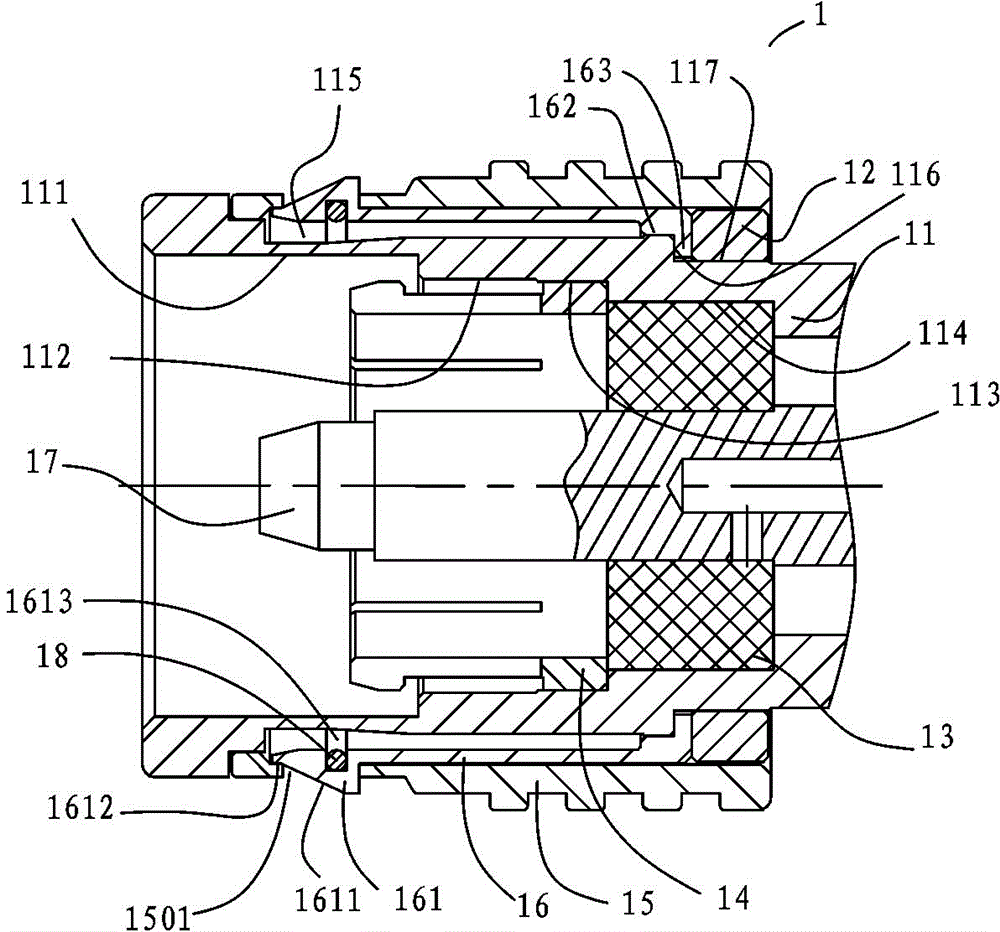

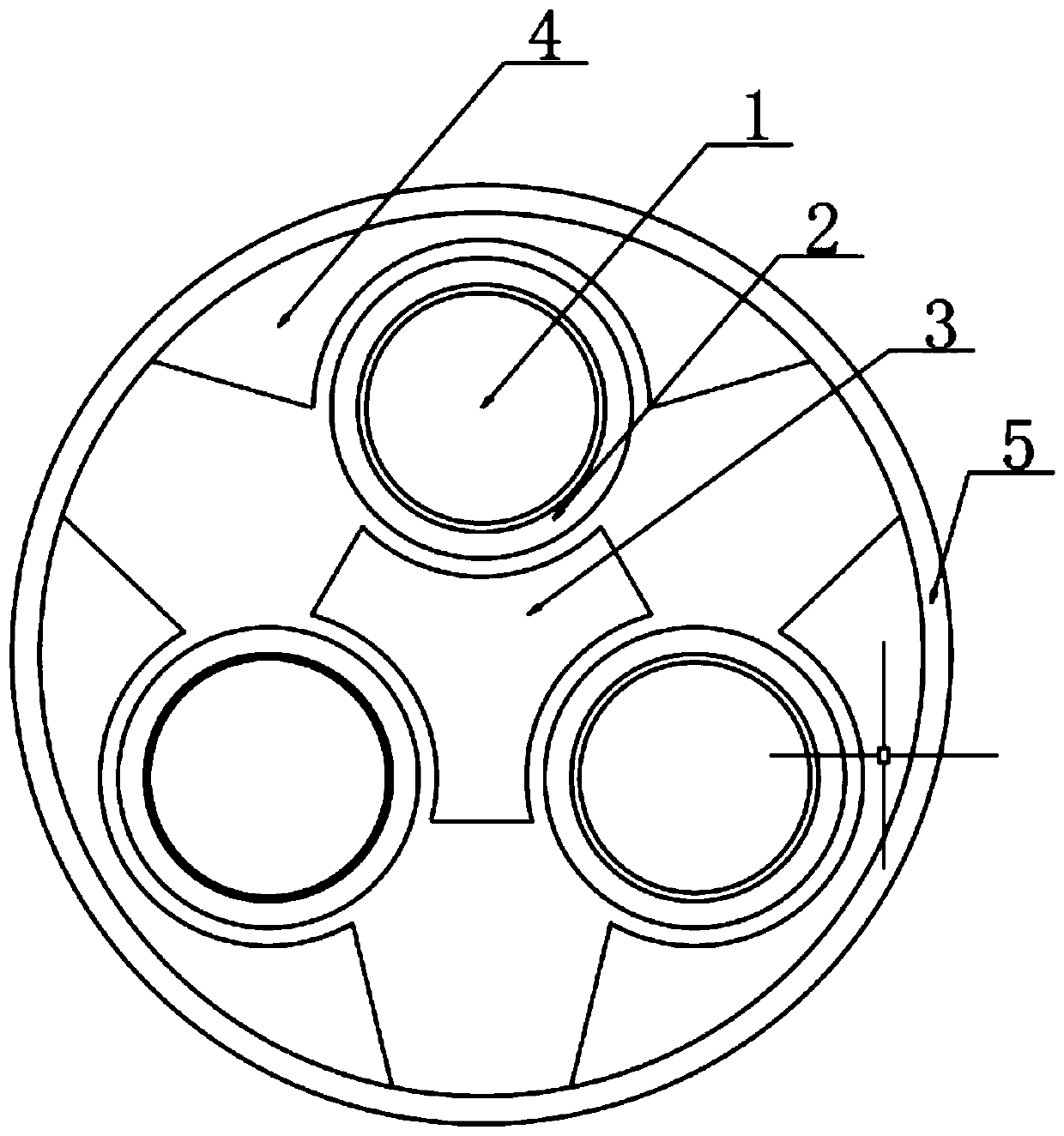

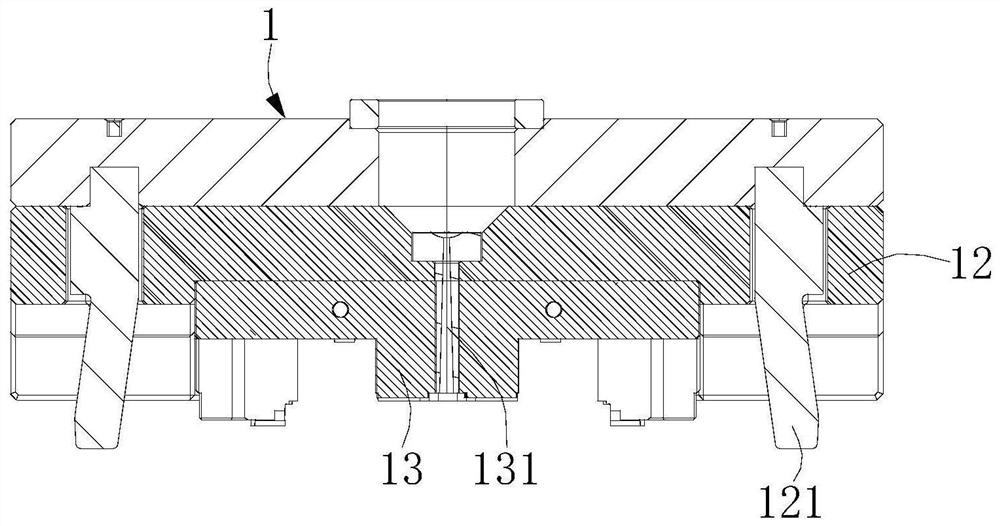

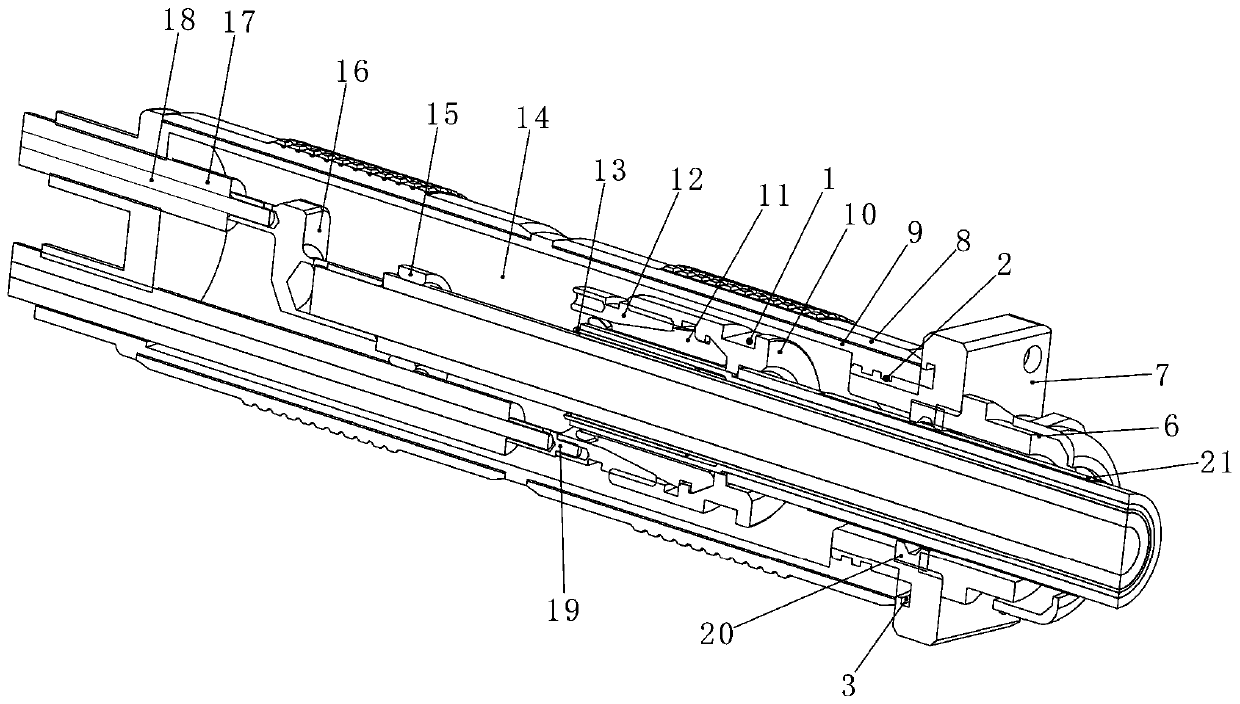

The invention provides a radio frequency coaxial electric coupler with a quick-locking device. The quick-locking device comprises a plug quick-locking device and a socket quick-locking device. The back of an elastic jack catch (16) of the plug quick-licking device is fixed on the plug outer conductor (11). The front portion of the elastic jack catch (16) extends with a snap joint (161). A cone face of the snap joint (1611) is arranged on the front lateral surface of the snap joint (161). The cone face of the snap joint (1611) of the elastic jack catch (16) enables the snap joint (161) to contract inward along the radial direction under the effect of the external force. The periphery of the elastic jack catch (16) is provided with a columnar-shaped unlocking sleeve (15). The plug quick-locking device refers to that a block groove (222) is formed on the front end of an outer conductor (22) of the plug along the axial direction. A catching groove (223) is formed radially outward on the wall of the block groove (222). The quick-locking device of the electric coupler has the advantages of being simple in structure, quick in product assembling, and saving the production cost of the quick-locking device.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

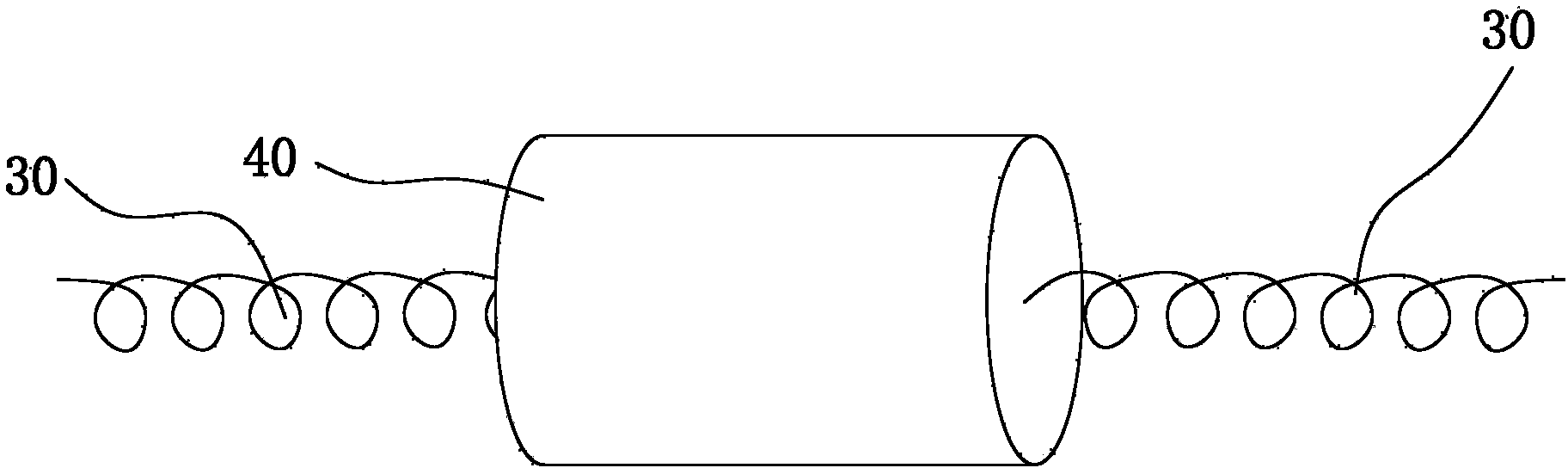

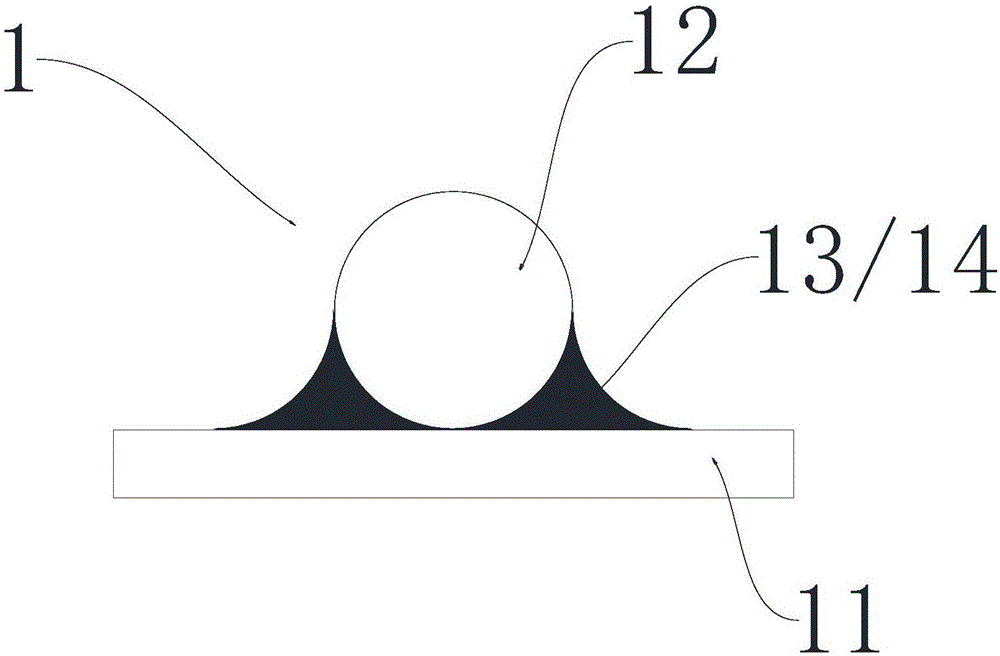

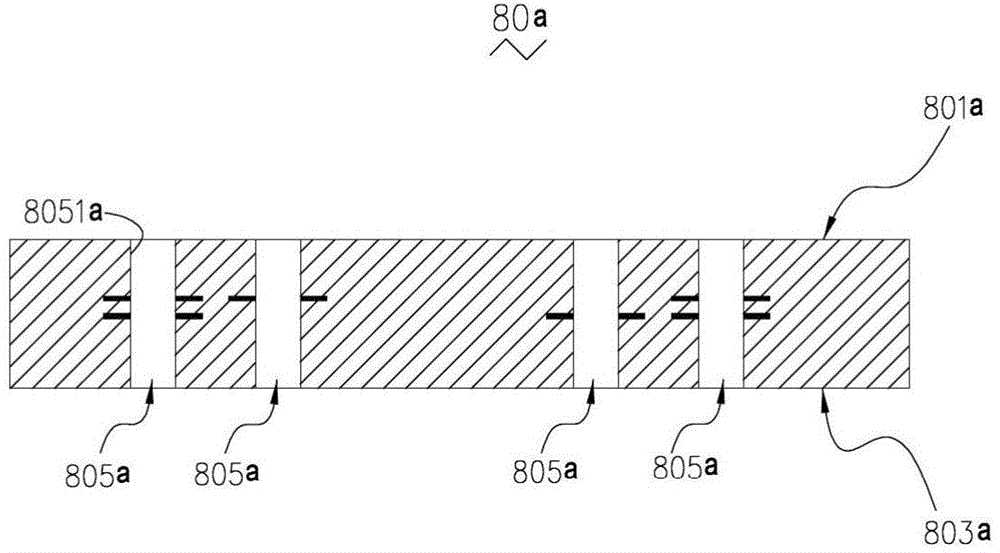

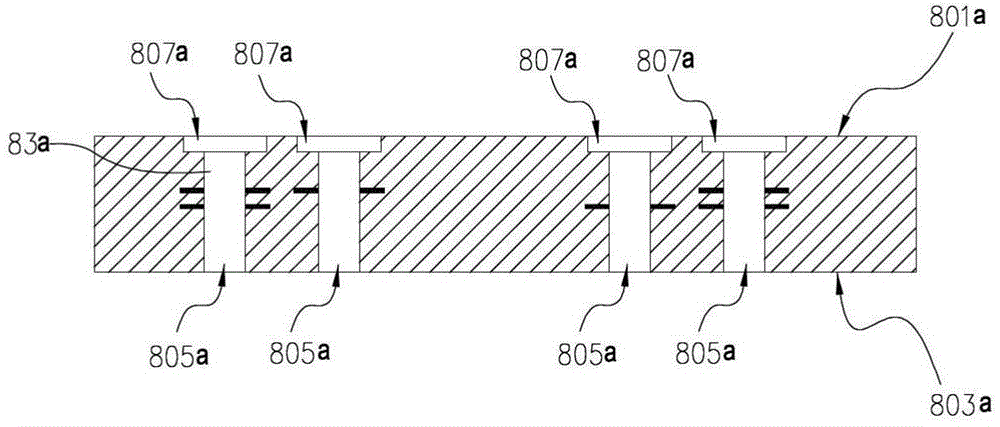

Electronic tag inlay, processing method of electronic tag inlay and electronic tag

InactiveCN104050497AReliable structureHigh strengthSoldering apparatusRecord carriers used with machinesDielectric slabElectrical and Electronics engineering

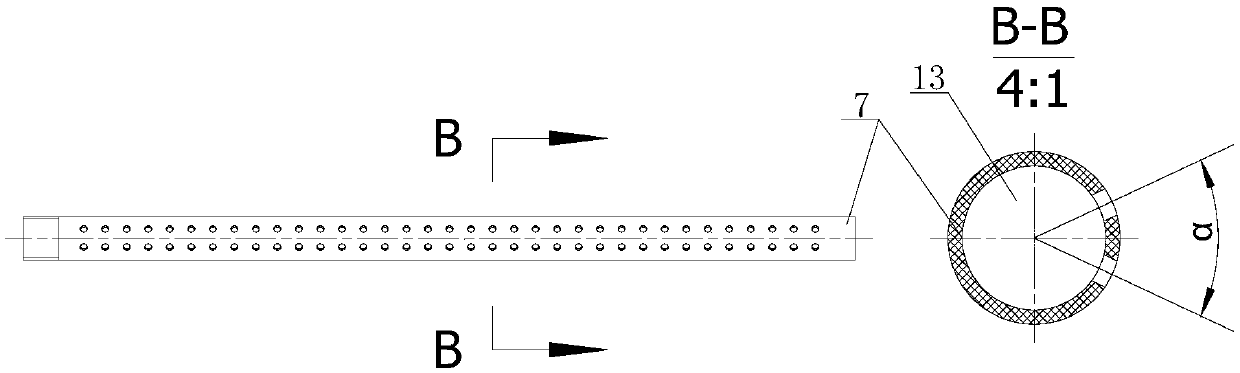

The invention relates to the technical field of radio frequency identification and provides an electronic tag inlay, a processing method of the electronic tag inlay and an electronic tag. The electronic tag inlay comprises a dielectric slab, a chip, an antenna, a protective material and a protective sheath, wherein a bonding pad is arranged on the dielectric slab, the chip and the antenna are respectively connected with the dielectric slab to achieve electrical breakover of the chip and the antenna, the protective material is packaged in the dielectric slab and the chip, connected to the outside of the antenna on the dielectric slab and used for sealing the chip, the dielectric slab and a connecting position of the chip and the antenna and bearing external force impact, and the protective sheath is located outside the protective material, wraps the dielectric slab, the chip, the antenna and the protective material and is used for preventing an outside environment from interfering the chip, the dielectric slab and the connecting position of the chip and the antenna and enhancing the structural strength of the electronic tag inlay. The electronic tag inlay is reliable in structure, high in strength and capable of being bent or stretched.

Owner:杨雪

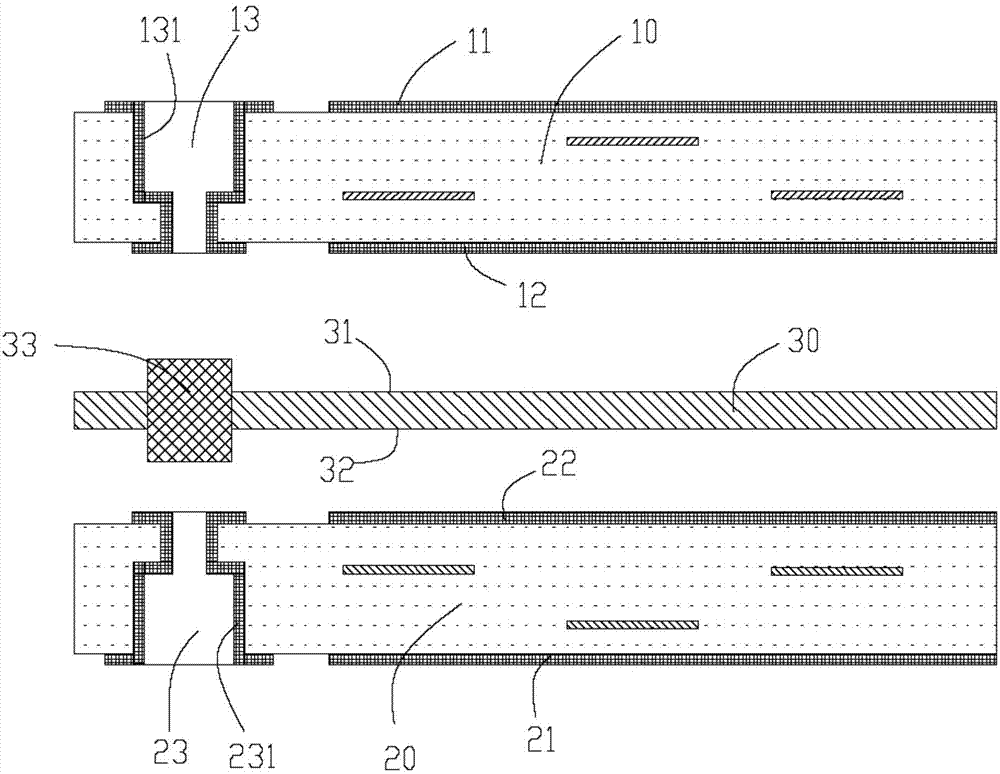

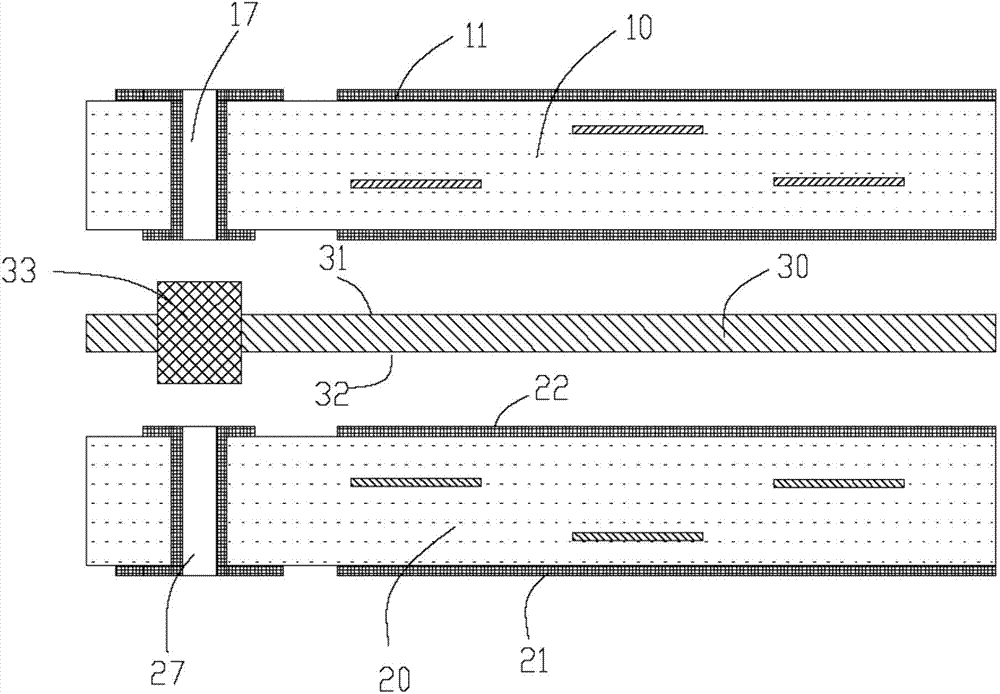

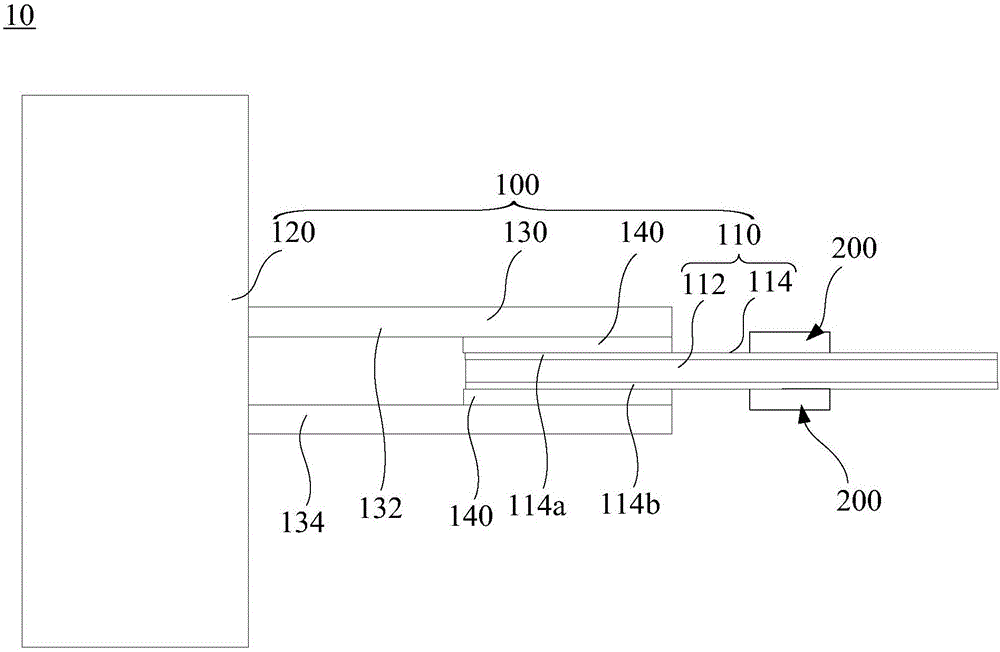

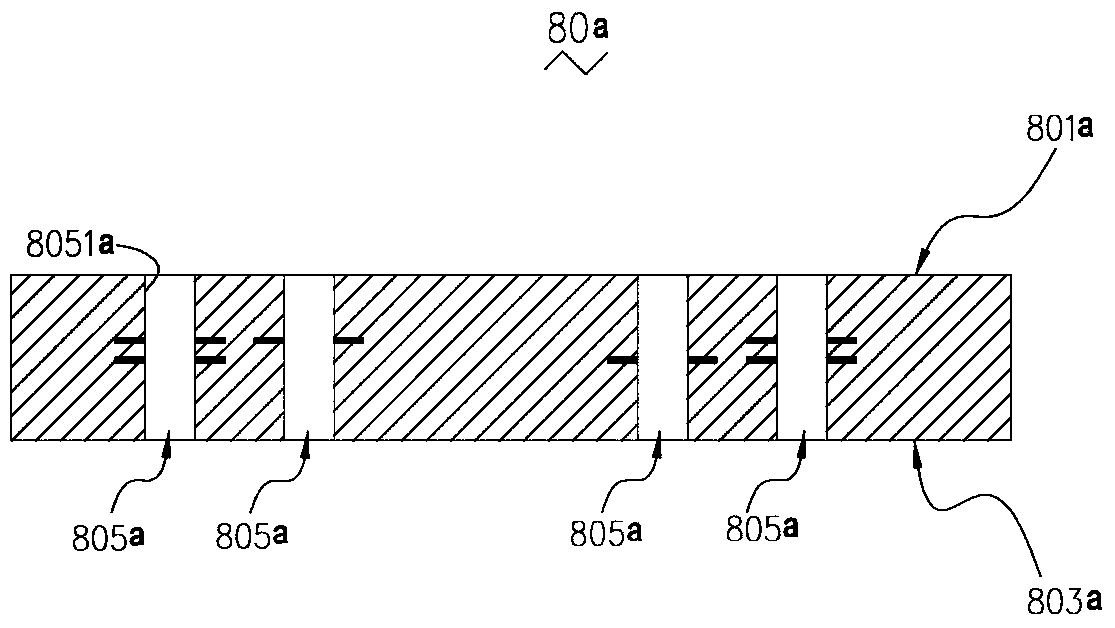

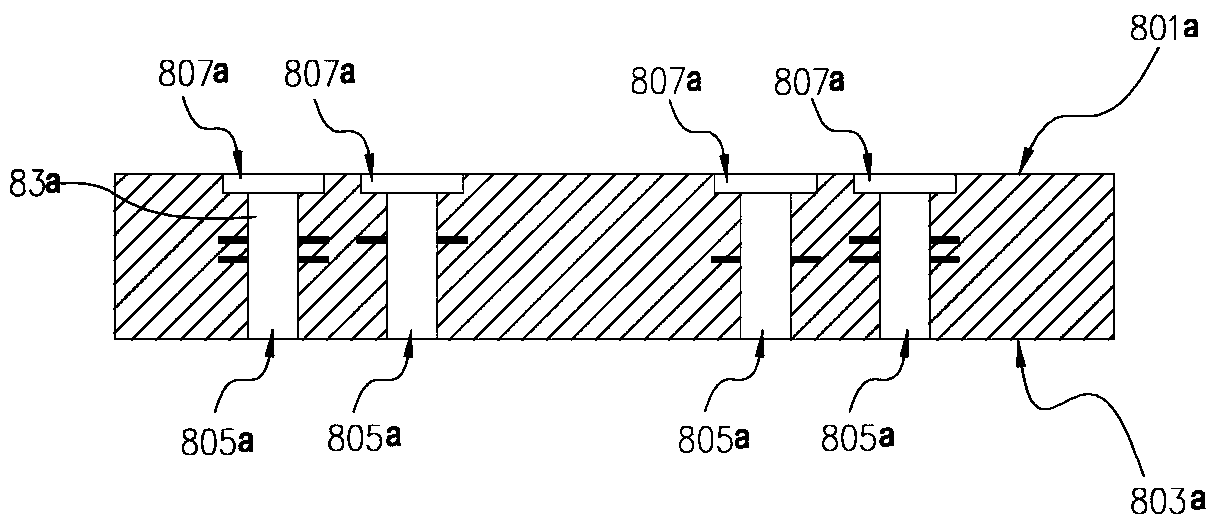

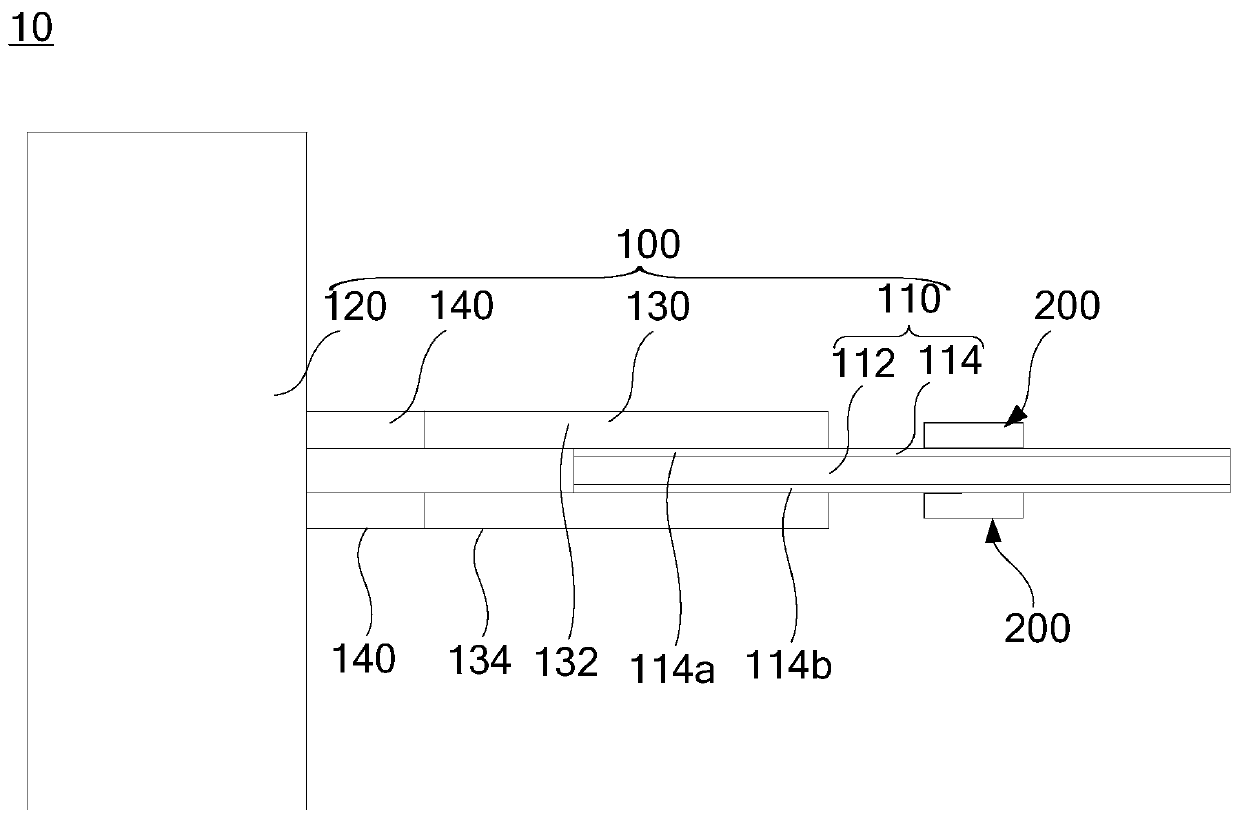

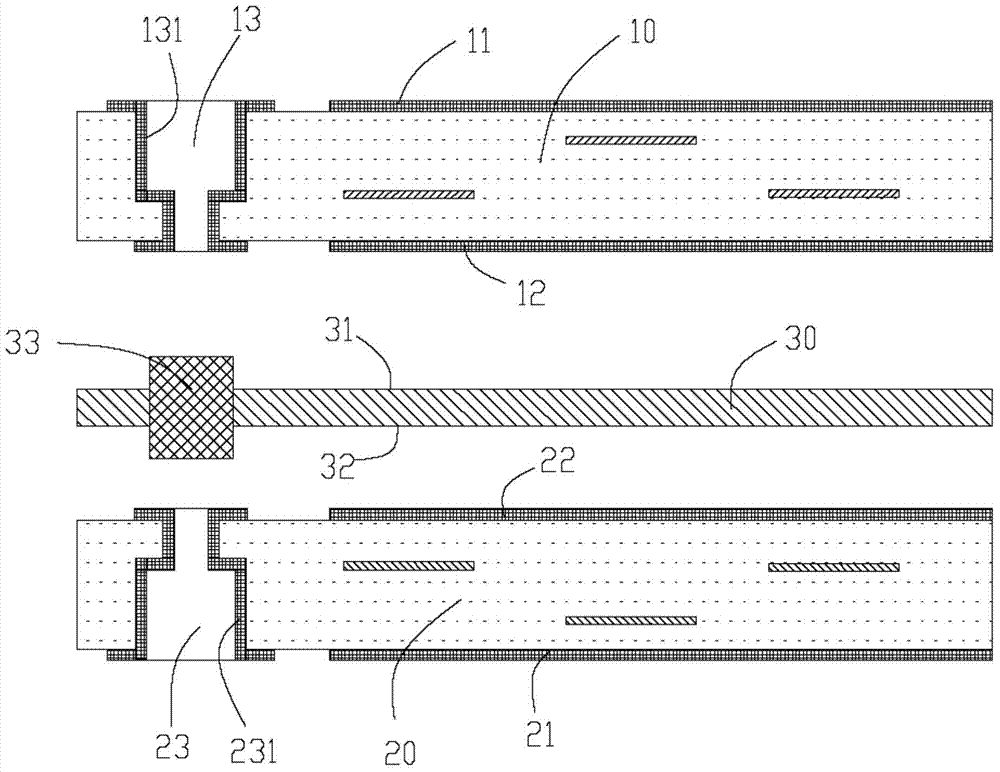

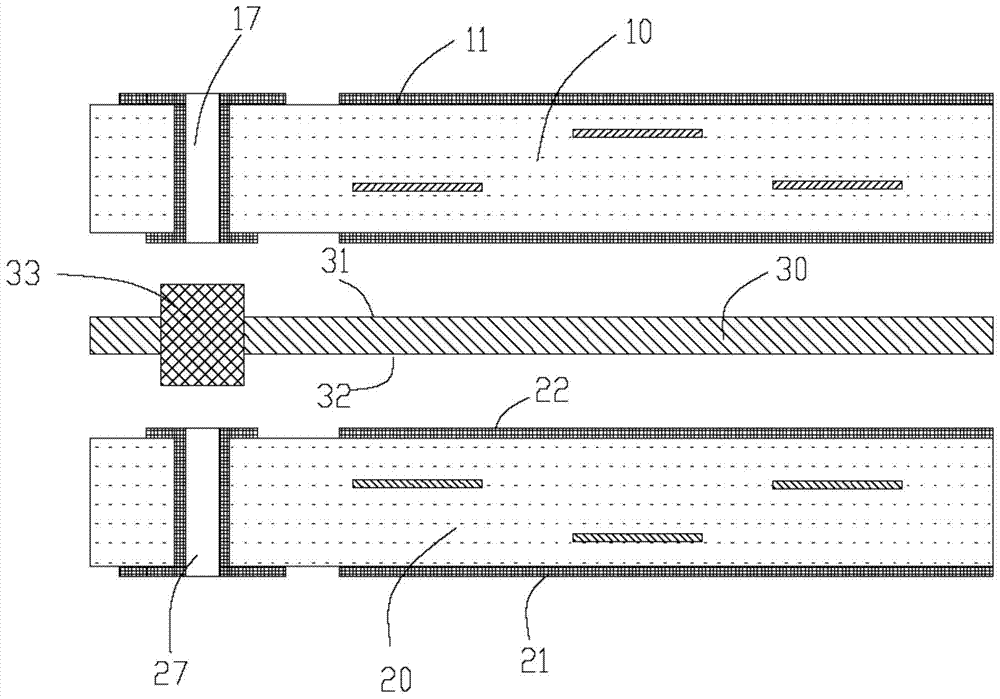

Printed circuit board and printed circuit board manufacturing method

ActiveCN104768326AAffect electrical performanceElectrical connection printed elementsPrinted element electric connection formationEngineeringMedia layer

The invention provides a printed circuit board. The printed circuit board comprises a plurality of sub board bodies. The sub board bodies comprise the first sub board body and the second sub board body. A first medium layer is arranged between the first sub board body and the second sub board body. The first sub board body is located on the outmost side of the printed circuit board. The first surface of the first medium layer is in press fit with the pressing face of the first sub board body, and the second surface is in press fit with the second sub board body. The part, protruding out of the first surface, of a first guide connection column covers hole openings of via holes of the first sub board body. The part, protruding out of the second surface, of the first guide connection column covers hole openings of via holes of the second sub board body so that a conductive metal layer of the via holes of the first sub board body can be electrically connected with a conductive meal layer of the via holes of the second sub board body in a breakover mode through the first guide connection column. The invention provides a printed circuit board manufacturing method.

Owner:HONOR DEVICE CO LTD

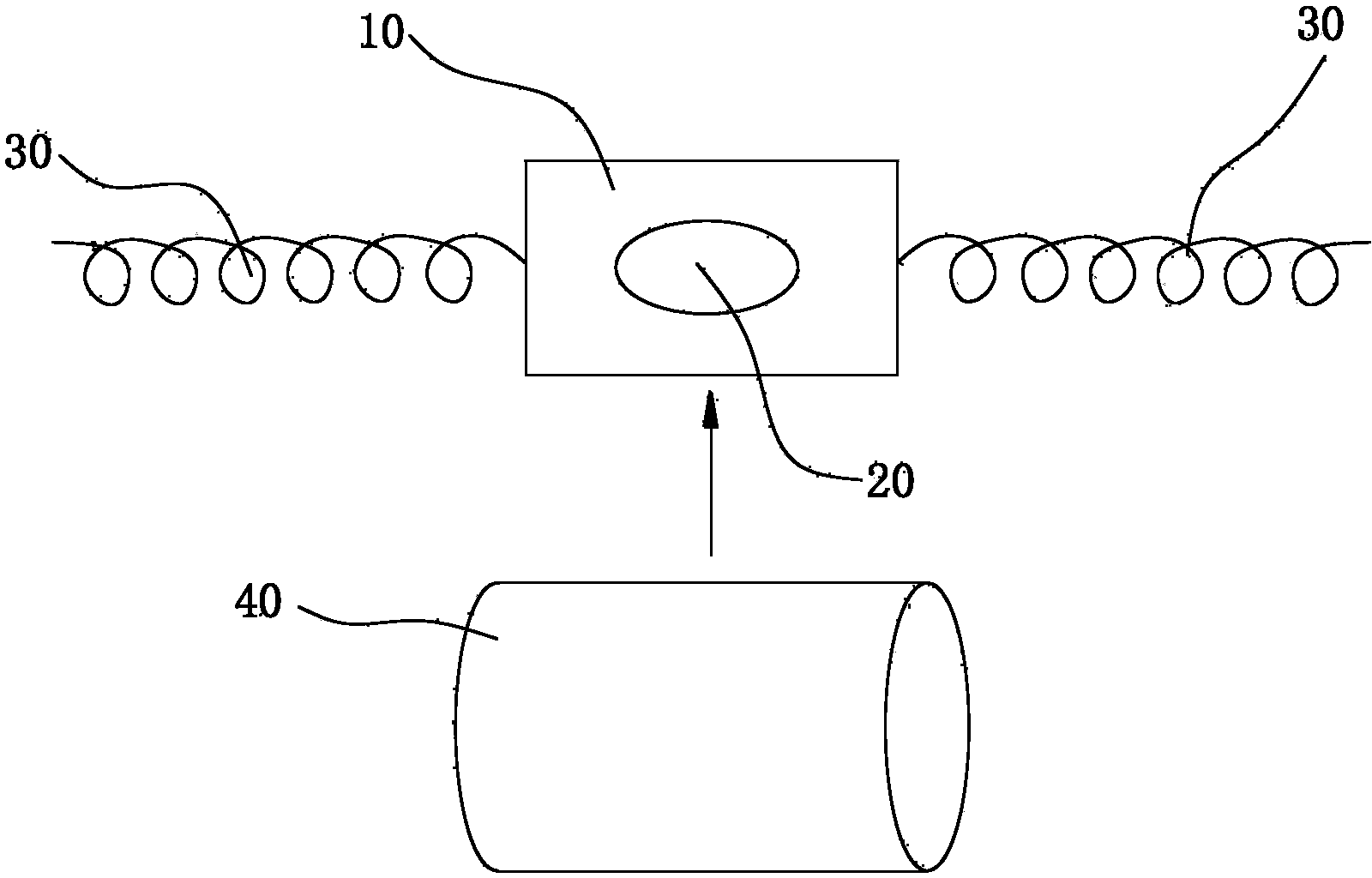

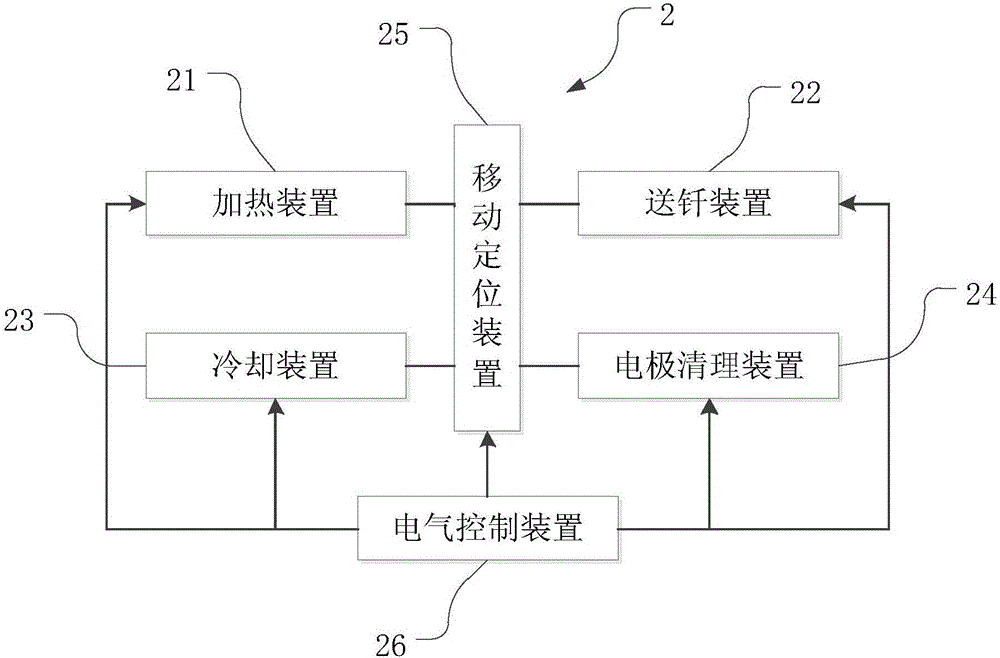

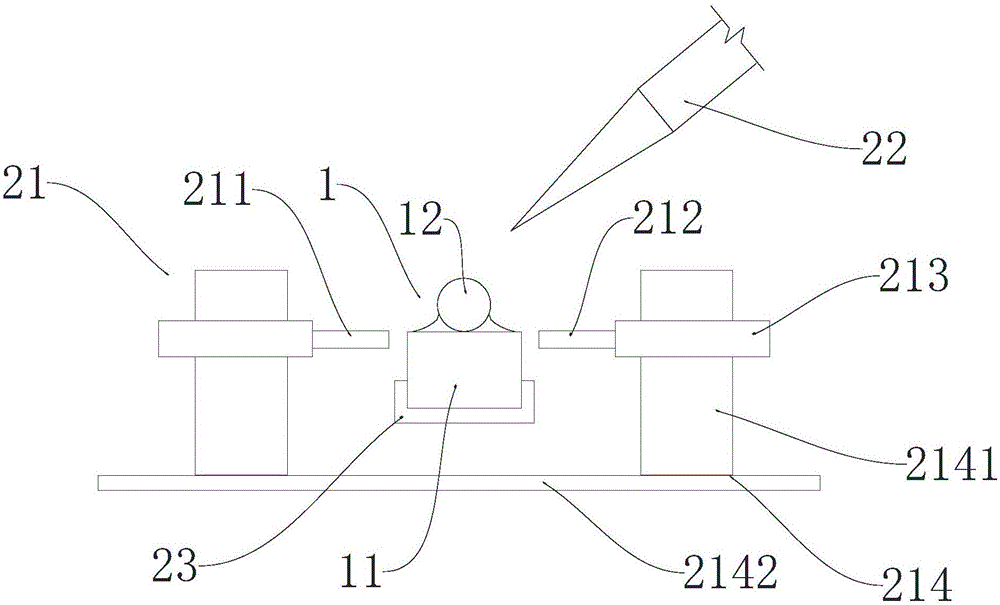

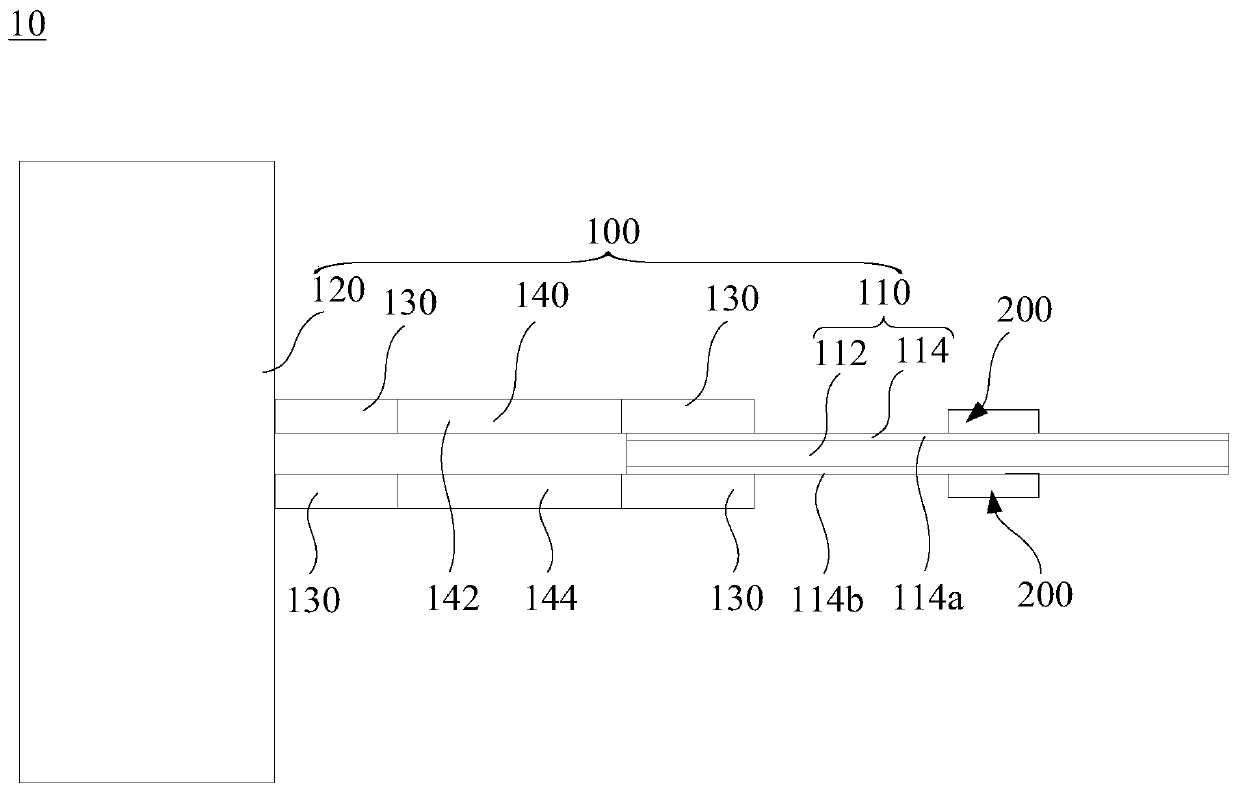

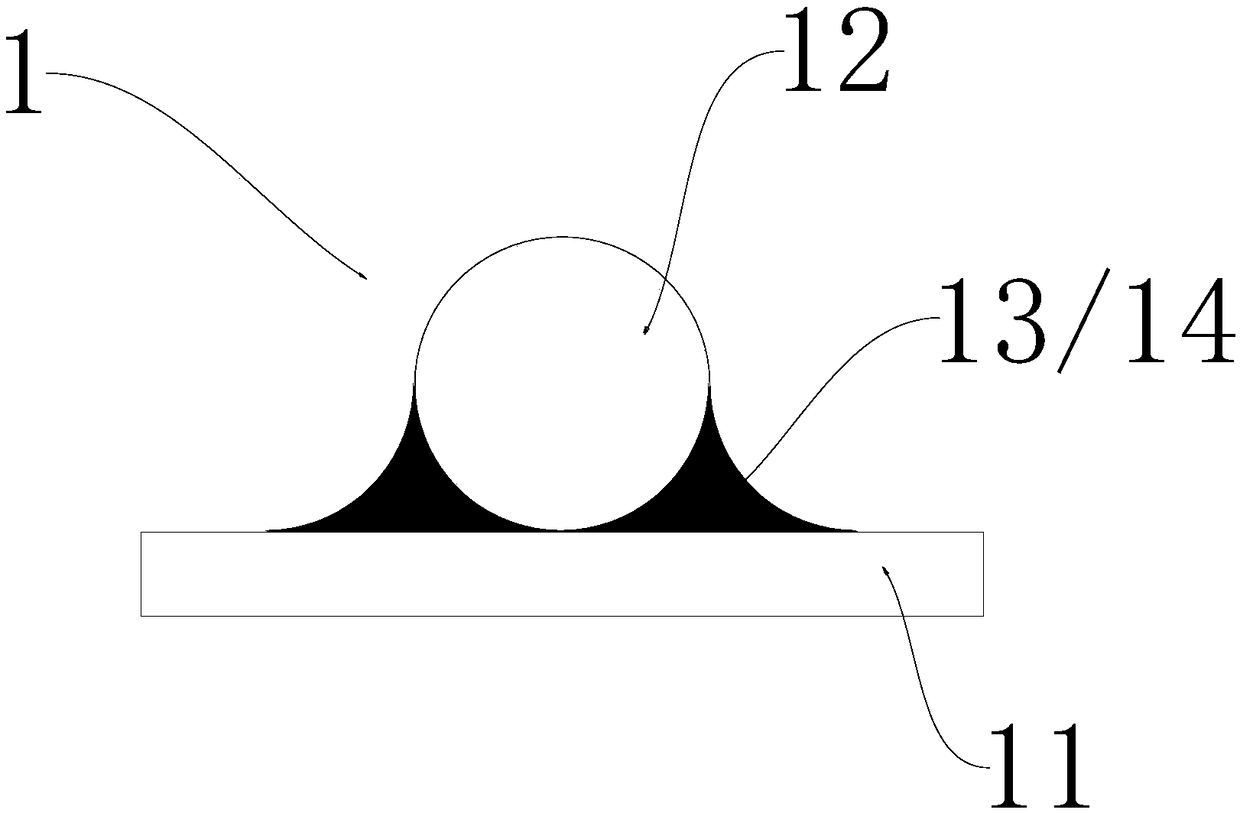

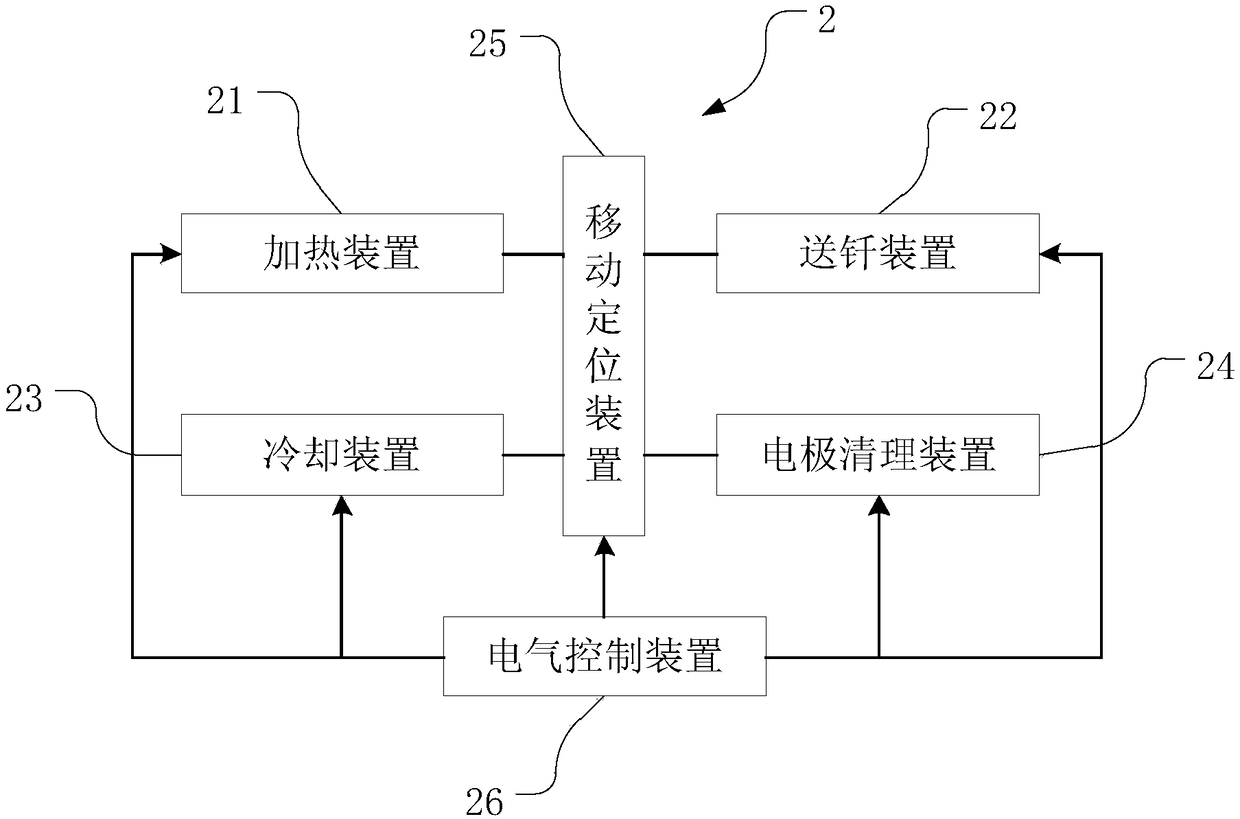

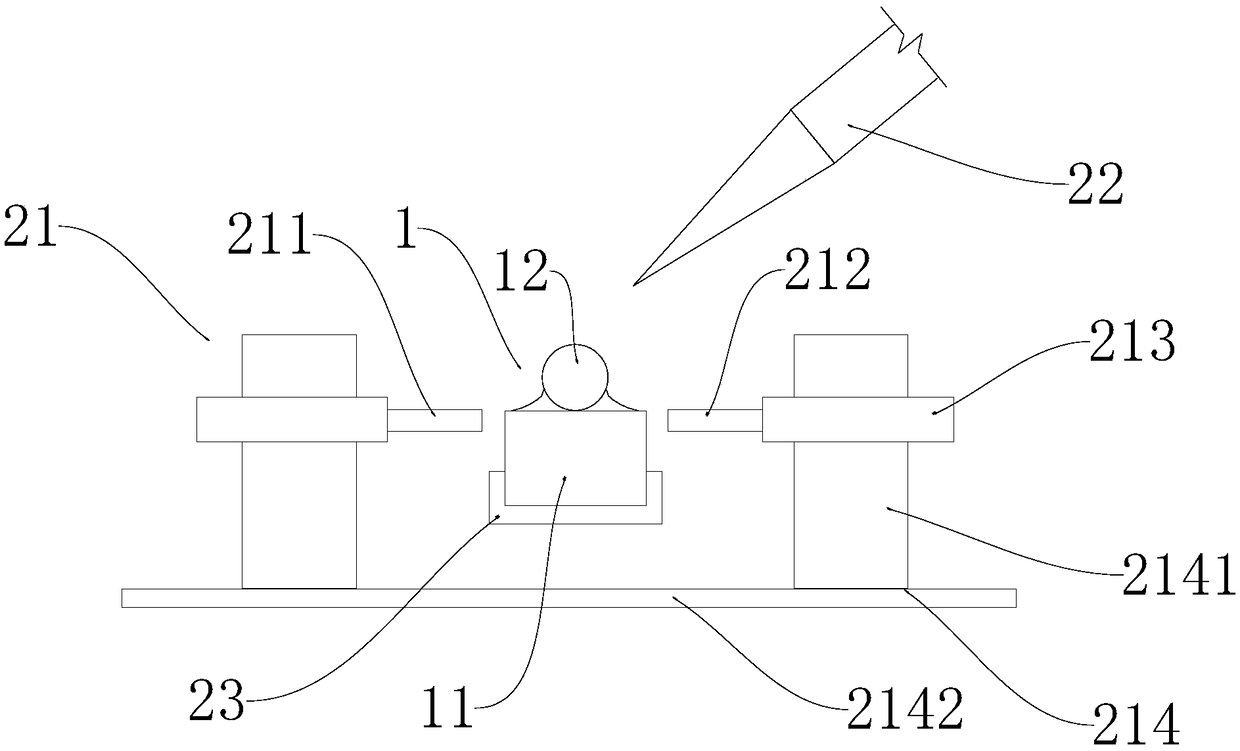

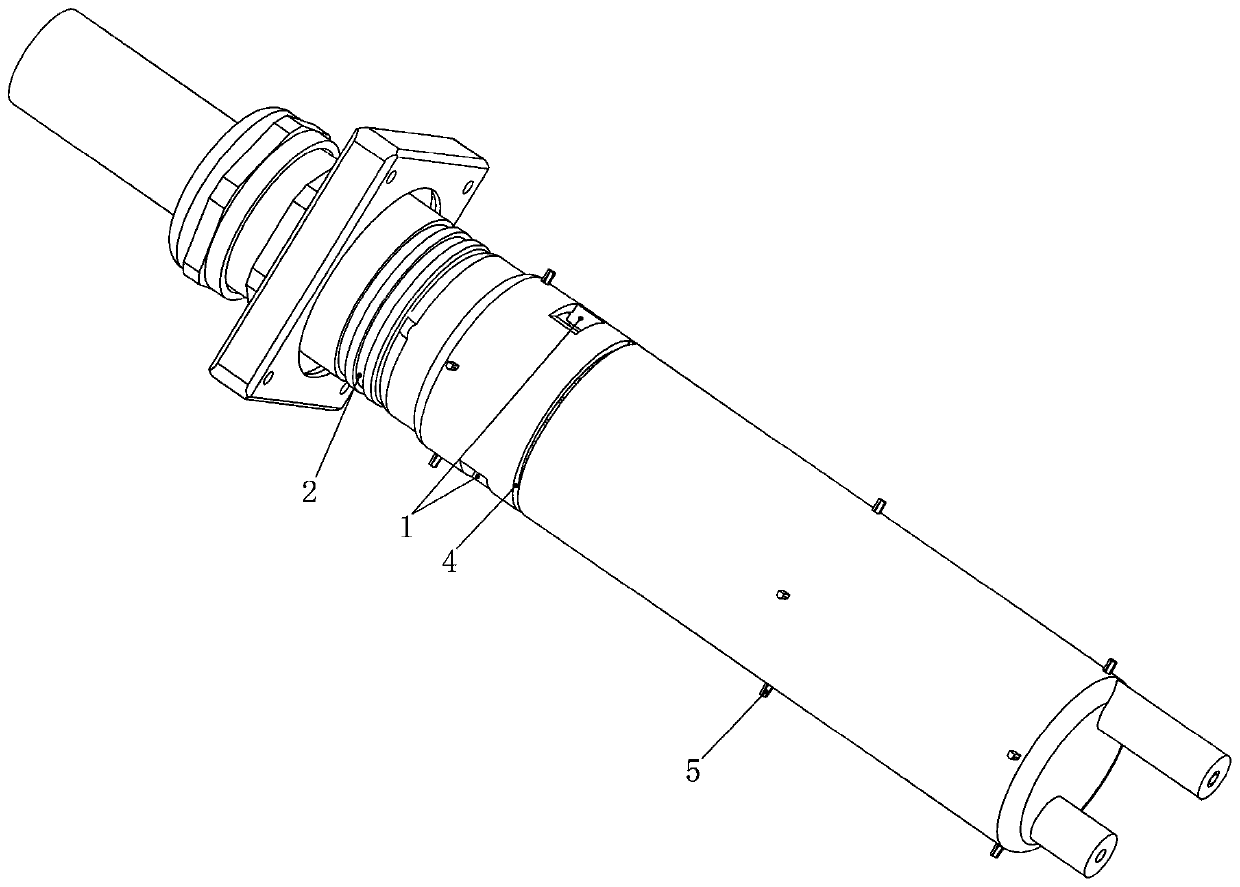

Welding system and welding method of metal piece and coaxial cable

ActiveCN106112163AGood thermal conductionReliable brazing connection structureLine/current collector detailsHeating appliancesEngineeringFiller metal

The invention discloses a welding system of a metal piece and a coaxial cable. The welding system comprises a heating device which is arranged at a processing station and is in contact with the metal piece or the coaxial cable to carry out heating, a solder feeding device which is arranged adjacent to the heating device and is used for adding brazing filler metal at a connecting part of the metal piece and the coaxial cable and a moving and positioning device which is used for separately clamping and transferring the metal piece and the coaxial cable to the processing station. The invention also discloses a welding method of the metal piece and the coaxial cable. The welding method comprises the following steps: preparing the metal piece and the coaxial cable, and transferring the metal piece and the coaxial cable to the processing station; adding the brazing filler metal at the connecting part of the metal piece and the coaxial cable at the processing station, and carrying out contact heating on the metal piece or the coaxial cable to realize welding; and transferring the welded metal piece from the processing station. According to the welding system and the welding method, the brazing reliability and conduction ratio of the metal piece and the coaxial cable can be well solved, the production efficiency can also be improved, and the production cost is lowered.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +2

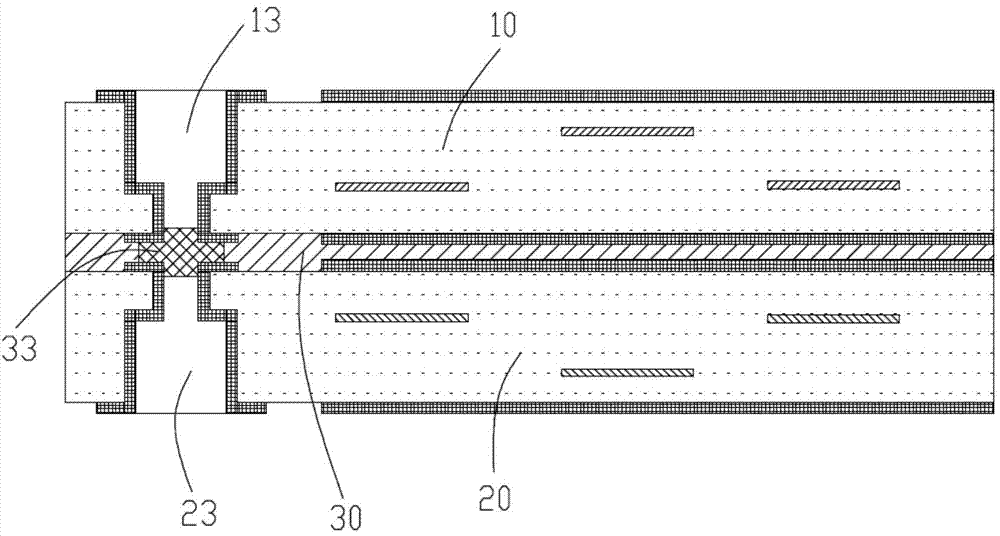

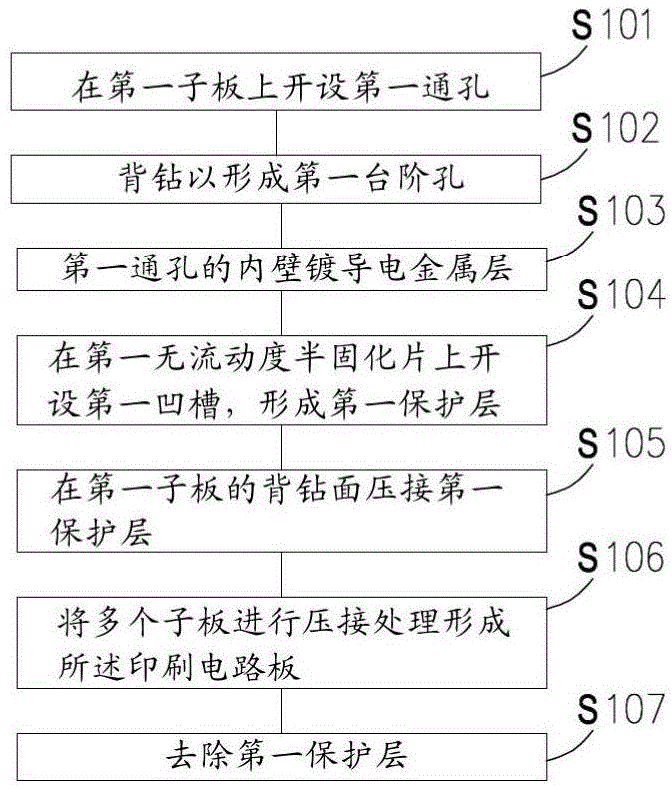

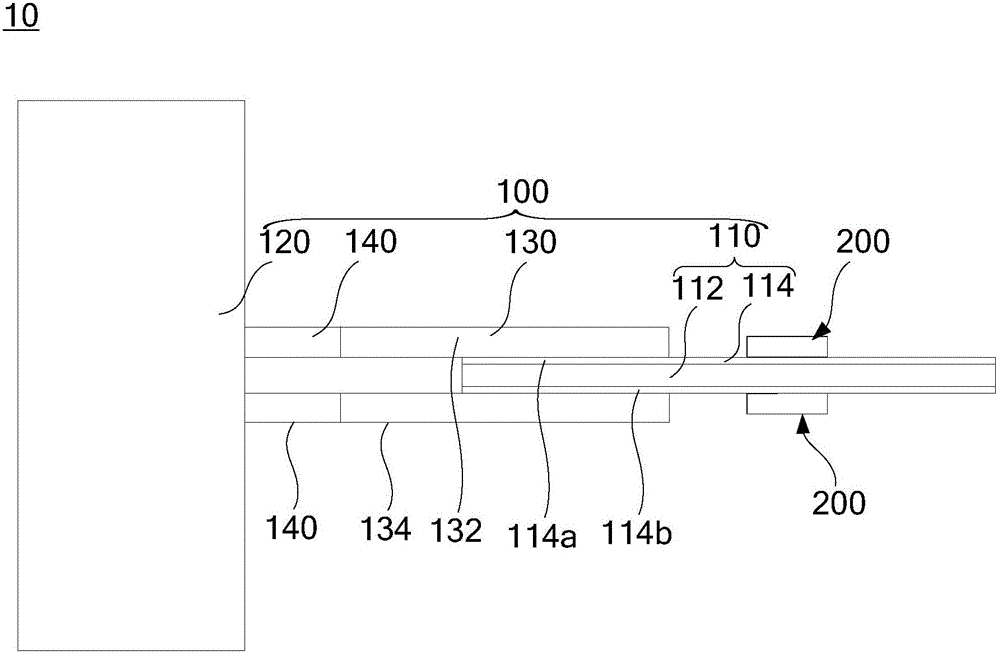

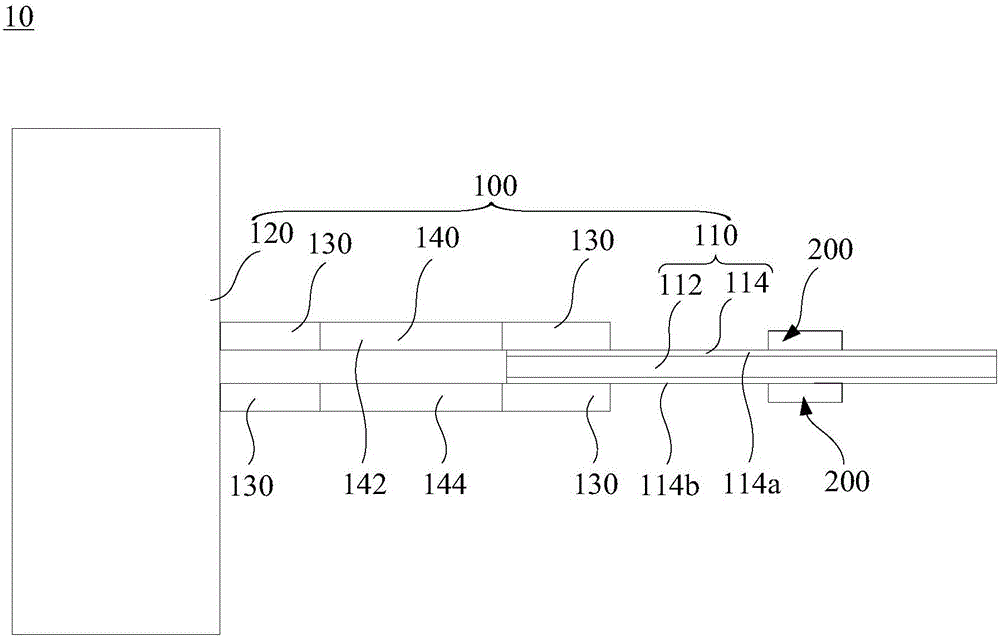

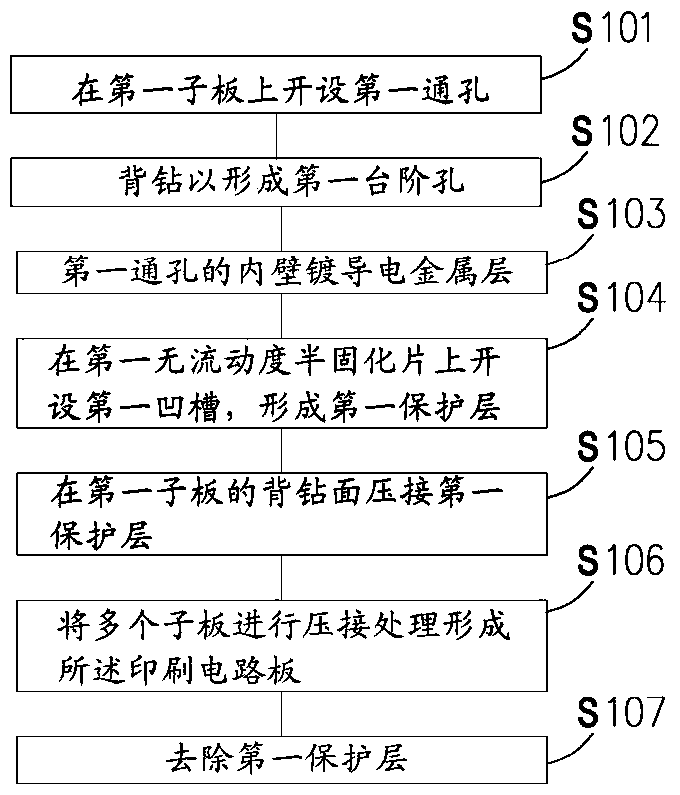

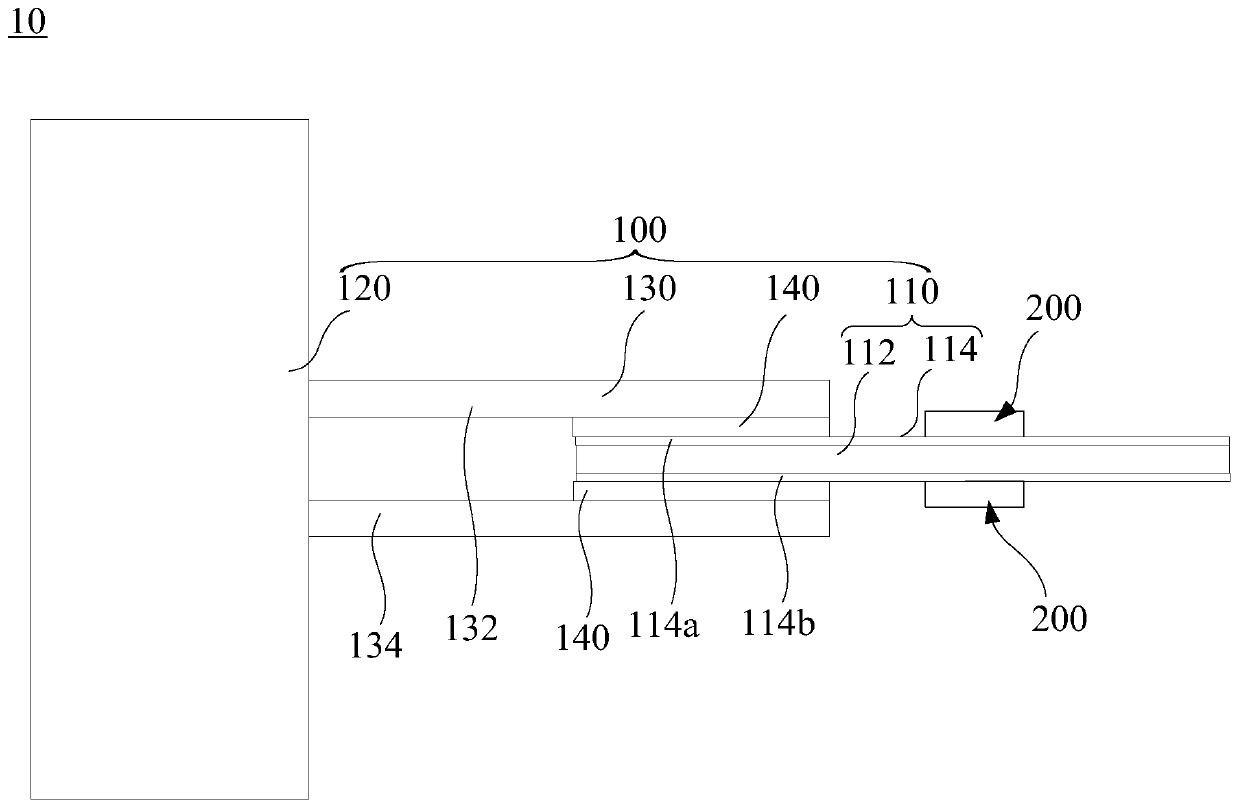

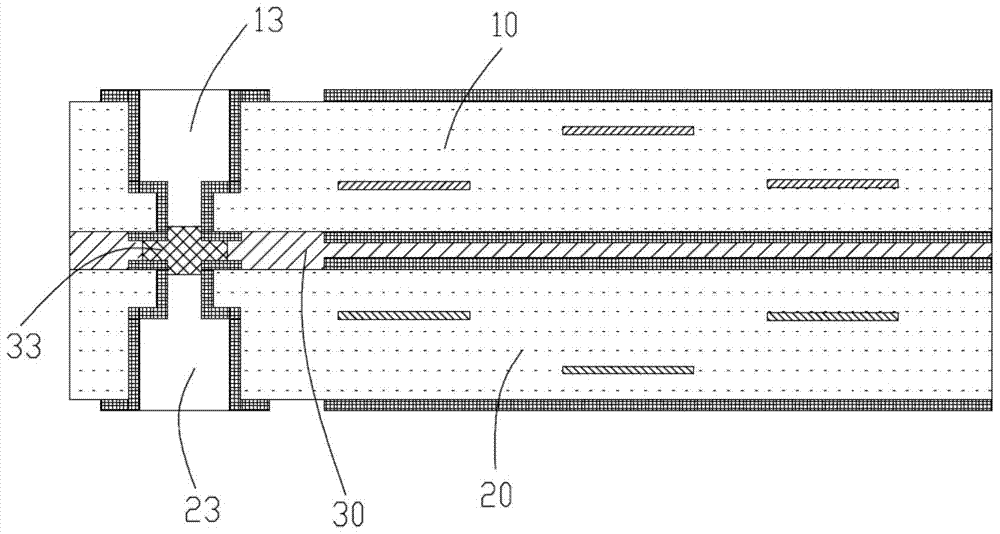

Printed circuit board and manufacturing method thereof

ActiveCN104661427AAffect electrical performanceElectrical connection printed elementsMultilayer circuit manufactureJoint surfacePrinted circuit board

The invention provides a printed circuit board. The printed circuit board comprises multiple daughter boards, wherein the daughter boards comprise a first daughter board located on the outermost side of the printed circuit board; at least one first through hole is formed in the first daughter board and penetrates through back drilling surface and a compression joint surface of the first daughter board; the wall of the first through hole is plated with a conductive metal layer; a first step hole is formed in the first daughter board in a back drilling manner and is communicated with the first through hole; the projection of the first step hole on the back drilling surface of the first daughter board covers the projection of the first through hole on the back drilling surface of the first daughter board; the first step hole is separated from other holes formed in the first daughter board. The invention further provides a manufacturing method of the printed circuit board. According to the printed circuit board and the method, the step hole is formed, so that accommodation space for accommodating a fluid is formed, and the fluid can be prevented from flowing into a blind hole of the printed circuit board.

Owner:HUAWEI TECH CO LTD

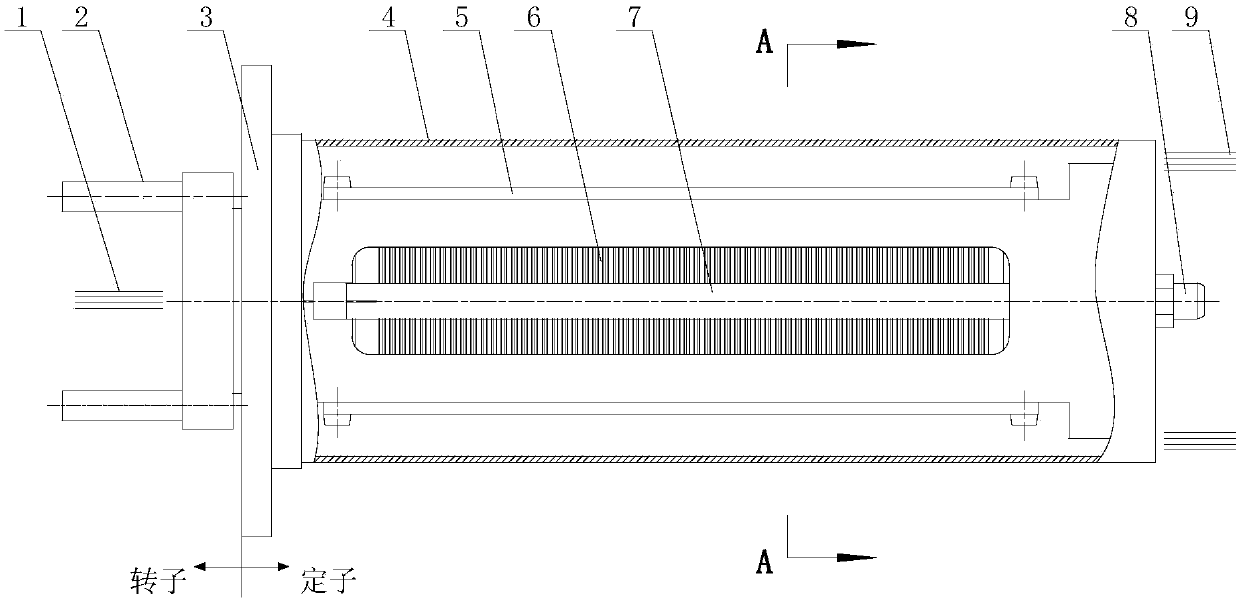

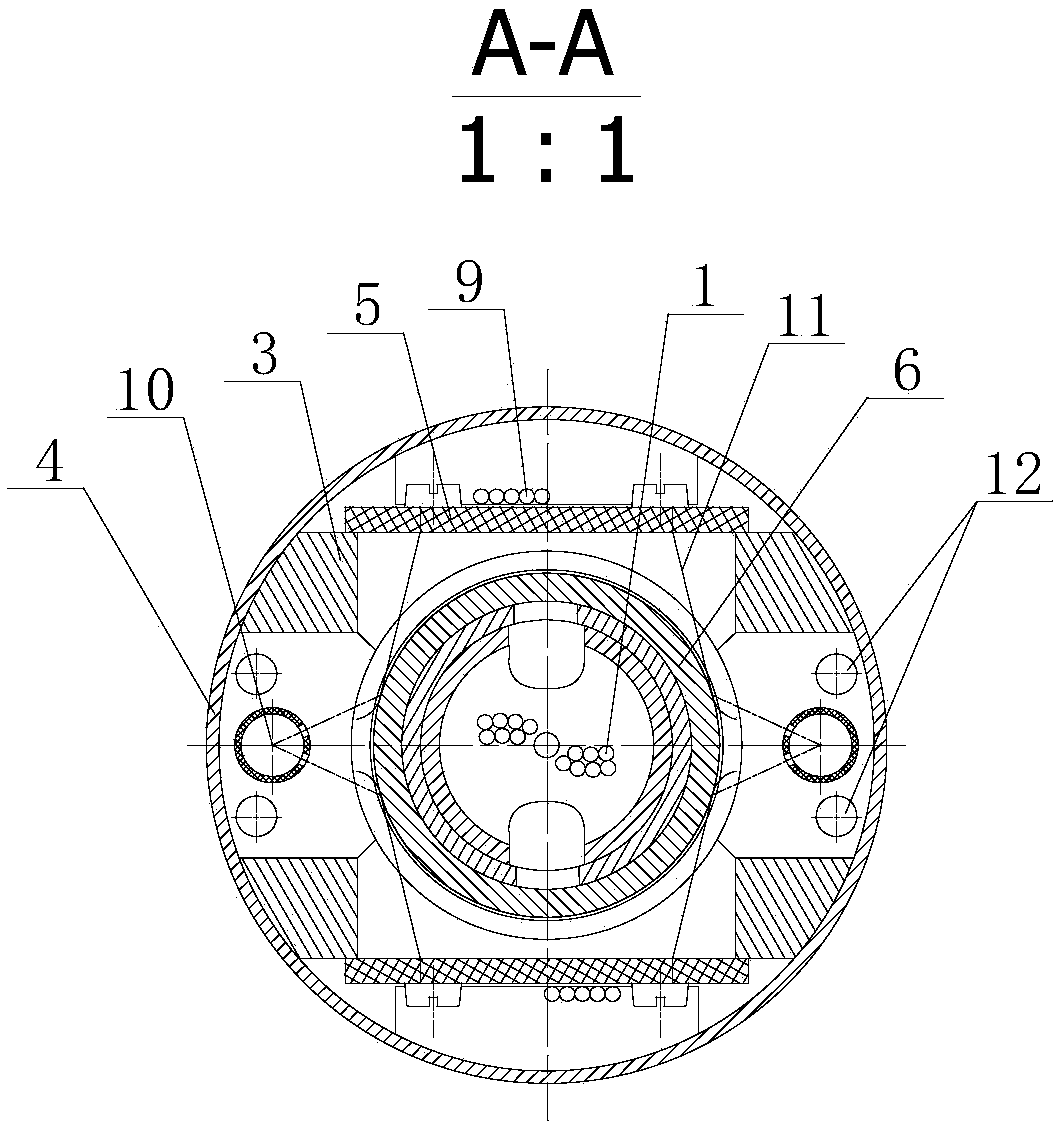

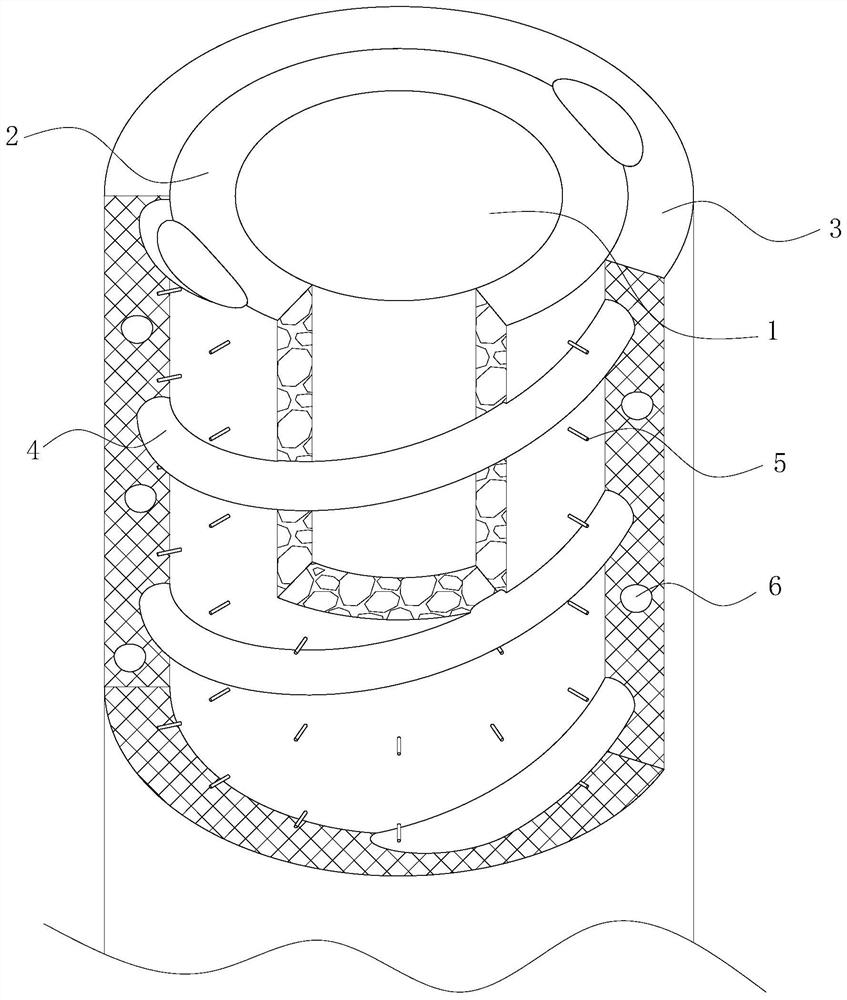

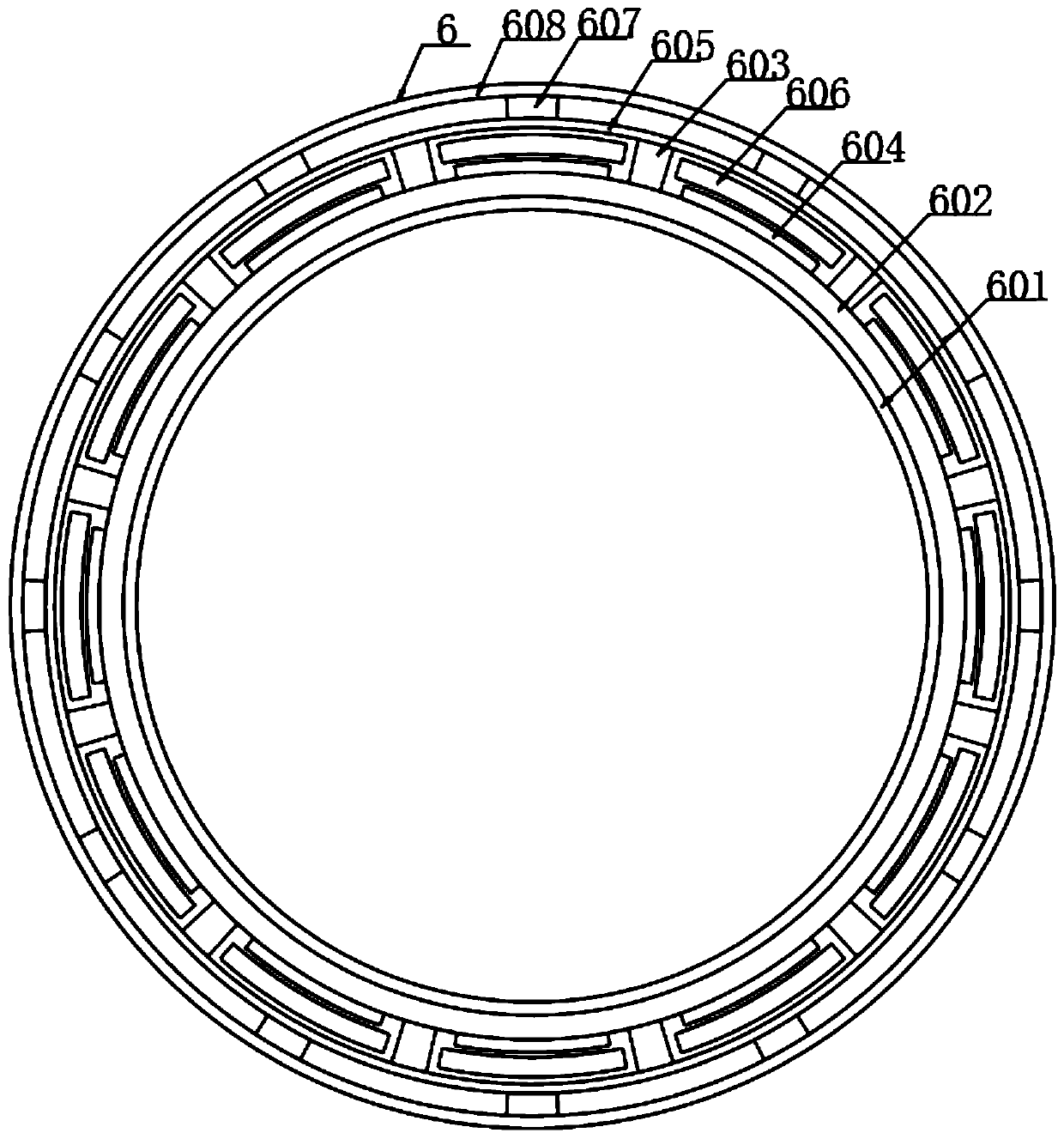

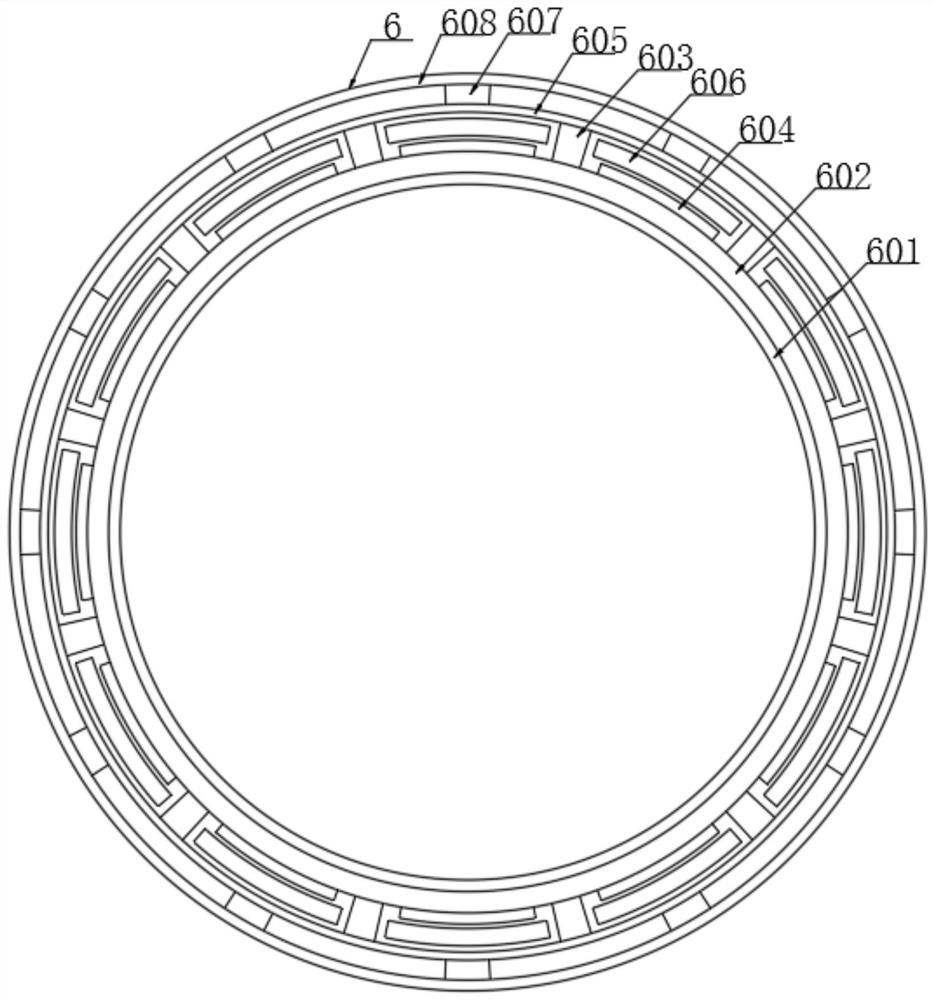

High-efficiency cooling structure for high-speed conductive slip ring

InactiveCN109659785AImprove heat transfer efficiencyAvoid destructionRotary current collectorModifications using gaseous coolantsEngineeringSlip ring

The invention discloses a high-efficiency cooling structure for a high-speed conductive slip ring. The structure comprises a ring outgoing line, a shifting fork, a bracket, an outer cover, a brush carrier plate, a ring piece, a core shaft, an air pipe, an air inlet hole, an air pipe joint, a brush outgoing line, an air inlet hole, a brush wire, an air outlet hole, a plug and a movable sealing ring. The core shaft, the ring piece fixed on the core shaft, the shifting fork and the ring outgoing line form a rotor part; the brush wire is fixed on the brush carrier plate, the brush carrier plate isfixed on the bracket through a bolt, and the outer cover and the bracket are assembled to form a stator part; the air inlet hole and the air outlet hole are formed in the same end of the bracket, andone ends of the two air pipes are connected with the symmetrical air inlet holes in the sliding ring, and the other ends are plugged by plugs and extend into the sliding ring; and outside the slip ring, the air pipe joint is connected with the air inlet, and the rotor part and the stator part rotate relatively through a bearing. The structure can greatly improve the cooling efficiency, and solvesthe problem that the heat exchange efficiency of a cooling medium and a temperature rise point is low when a slip ring insulation sheet is too high or a friction point is deep.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

Radio frequency coaxial electric coupler with quick-locking device

ActiveCN103094782BSaving retaining ringLow production costSecuring/insulating coupling contact membersCoupling contact membersElectricityElectrical conductor

The invention provides a radio frequency coaxial electric coupler with a quick-locking device. The quick-locking device comprises a plug quick-locking device and a socket quick-locking device. The back of an elastic jack catch (16) of the plug quick-licking device is fixed on the plug outer conductor (11). The front portion of the elastic jack catch (16) extends with a snap joint (161). A cone face of the snap joint (1611) is arranged on the front lateral surface of the snap joint (161). The cone face of the snap joint (1611) of the elastic jack catch (16) enables the snap joint (161) to contract inward along the radial direction under the effect of the external force. The periphery of the elastic jack catch (16) is provided with a columnar-shaped unlocking sleeve (15). The plug quick-locking device refers to that a block groove (222) is formed on the front end of an outer conductor (22) of the plug along the axial direction. A catching groove (223) is formed radially outward on the wall of the block groove (222). The quick-locking device of the electric coupler has the advantages of being simple in structure, quick in product assembling, and saving the production cost of the quick-locking device.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

Lamp and heat dissipation mechanism thereof

ActiveCN106594690AAffect electrical performanceSolve the problem of low heat conduction efficiencyElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringHeat sink

The invention relates to a lamp and a heat dissipation mechanism thereof. The heat dissipation mechanism is used for dissipating heat generated by lamp beads and comprises a substrate, heat dissipation pieces, connecting columns and insulating blocks; the substrate is composed of a substrate body and thermal conductive layers; the thermal conductive layers are arranged on the outer wall of the substrate body, and the lamp beads are arranged on the thermal conductive layers respectively; each connecting column has the thermal conductivity and is arranged between the substrate body and the corresponding heat dissipation piece; and each insulating block has the thermal conductivity and is arranged between the substrate body and the corresponding heat dissipation piece to enable insulation to exist between each thermal conductive layer and the corresponding heat dissipation piece. According to the lamp and the heat dissipation mechanism thereof, heat generated by the lamp beads sequentially passes through the thermal conductive layers, the connecting columns, the insulating blocks and the heat dissipation pieces, or the heat generated by the lamp beads sequentially passes through the thermal conductive layers, the connecting column, the insulating blocks, the connecting column and the heat dissipation pieces, so that the problem of lower thermal conduction efficiency of a car lamp is solved, and the service life of the car lamp can be prolonged.

Owner:SHENZHEN YIKE PHOTOELECTRIC TECH

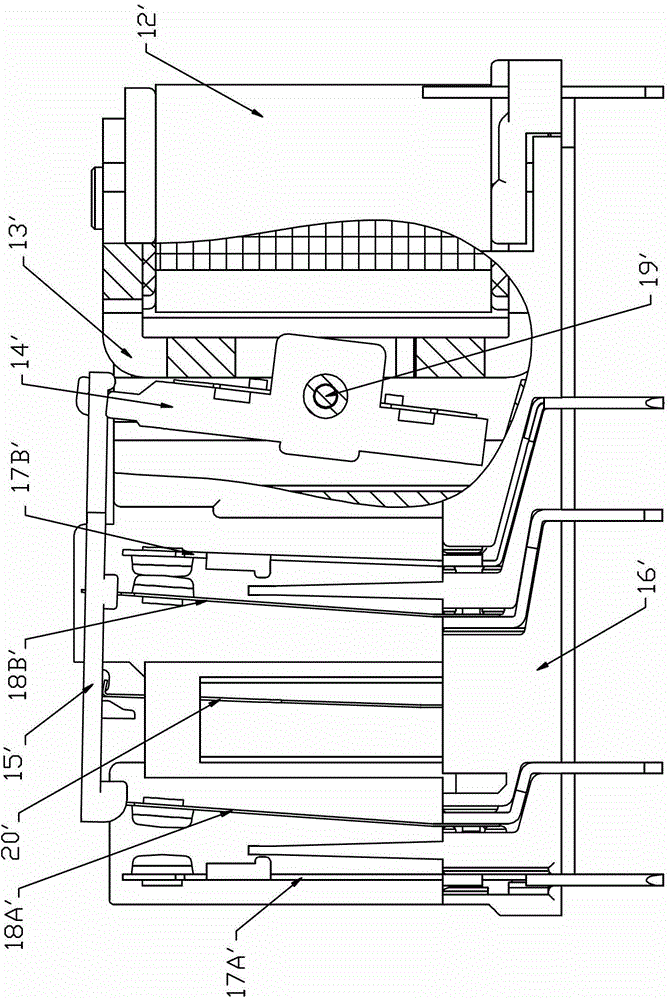

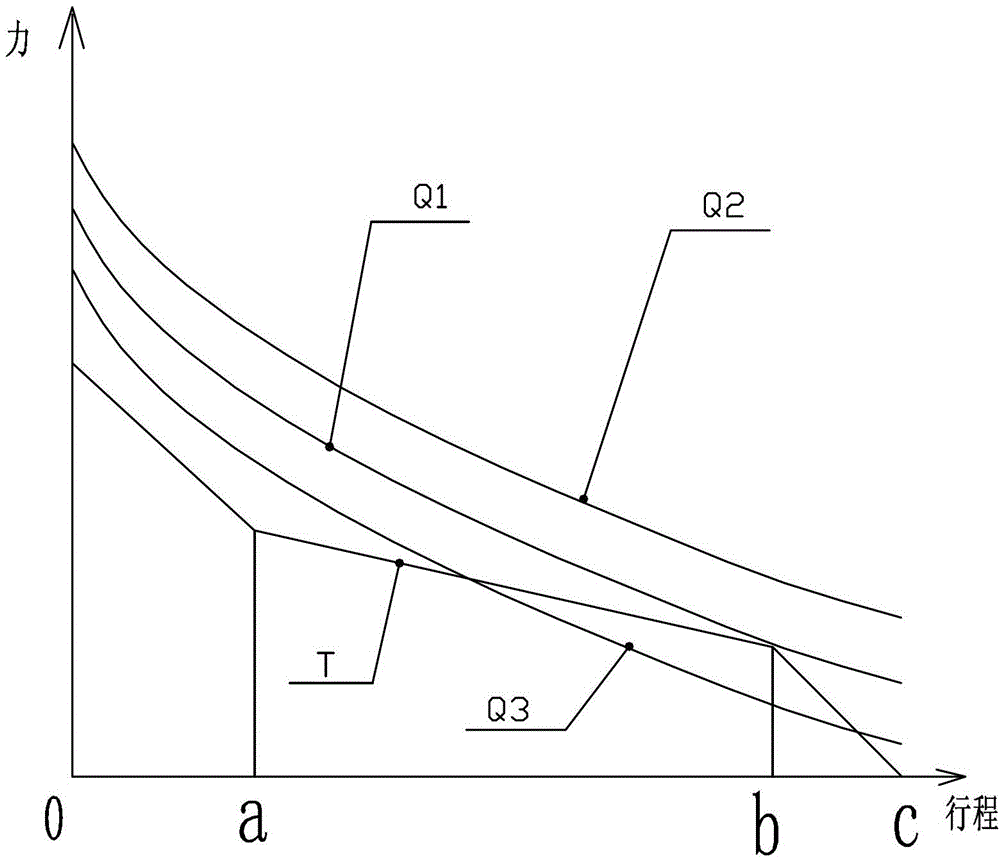

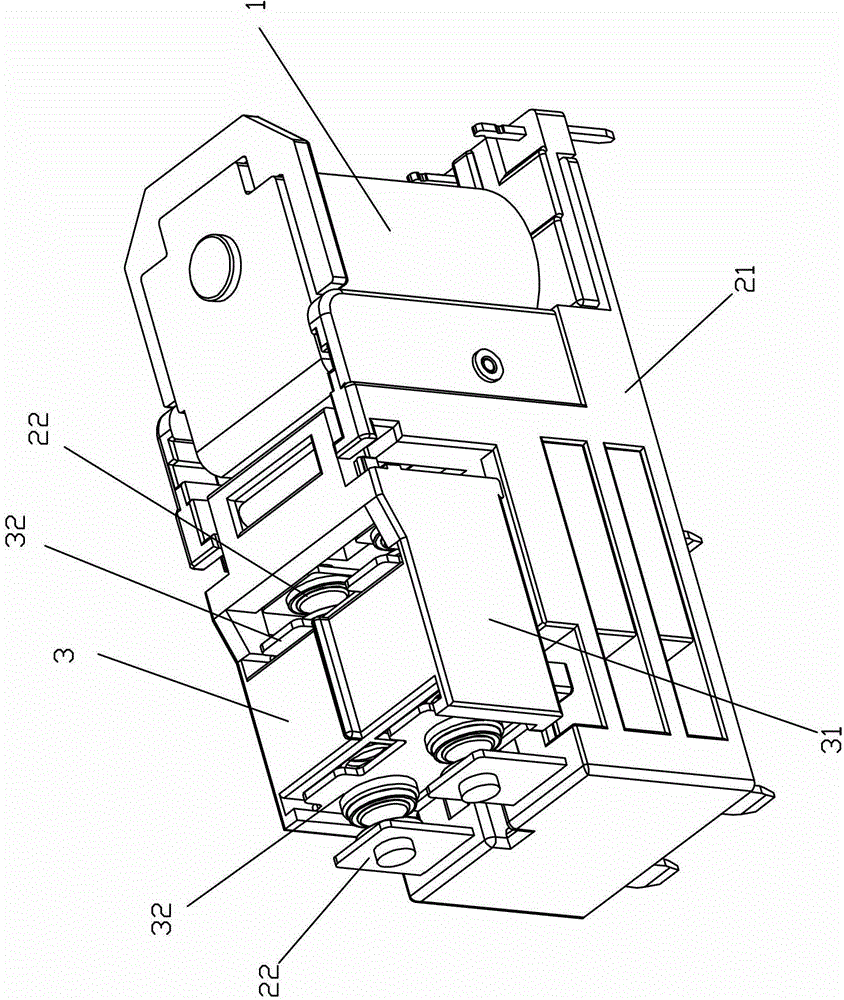

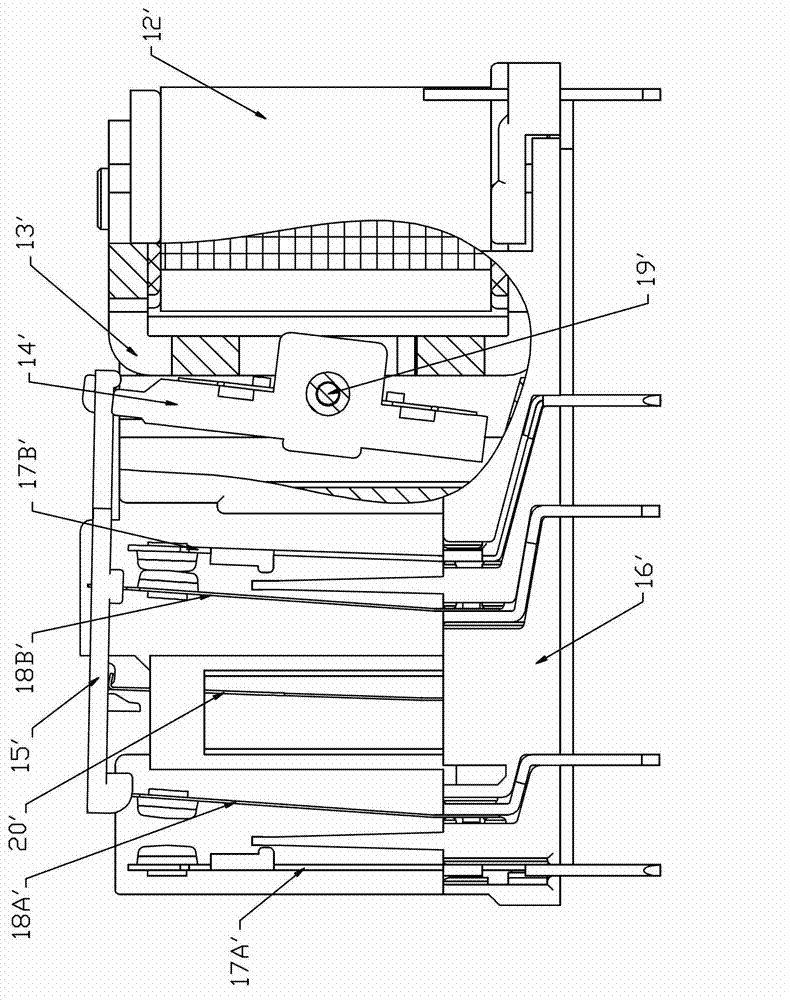

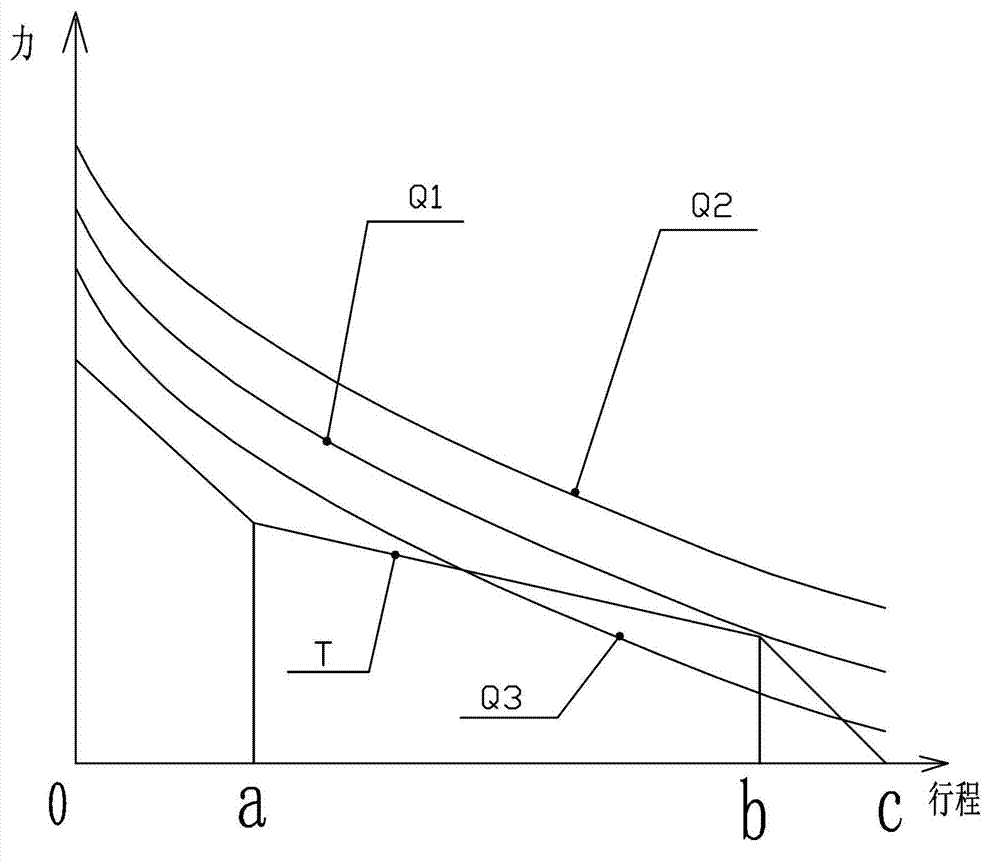

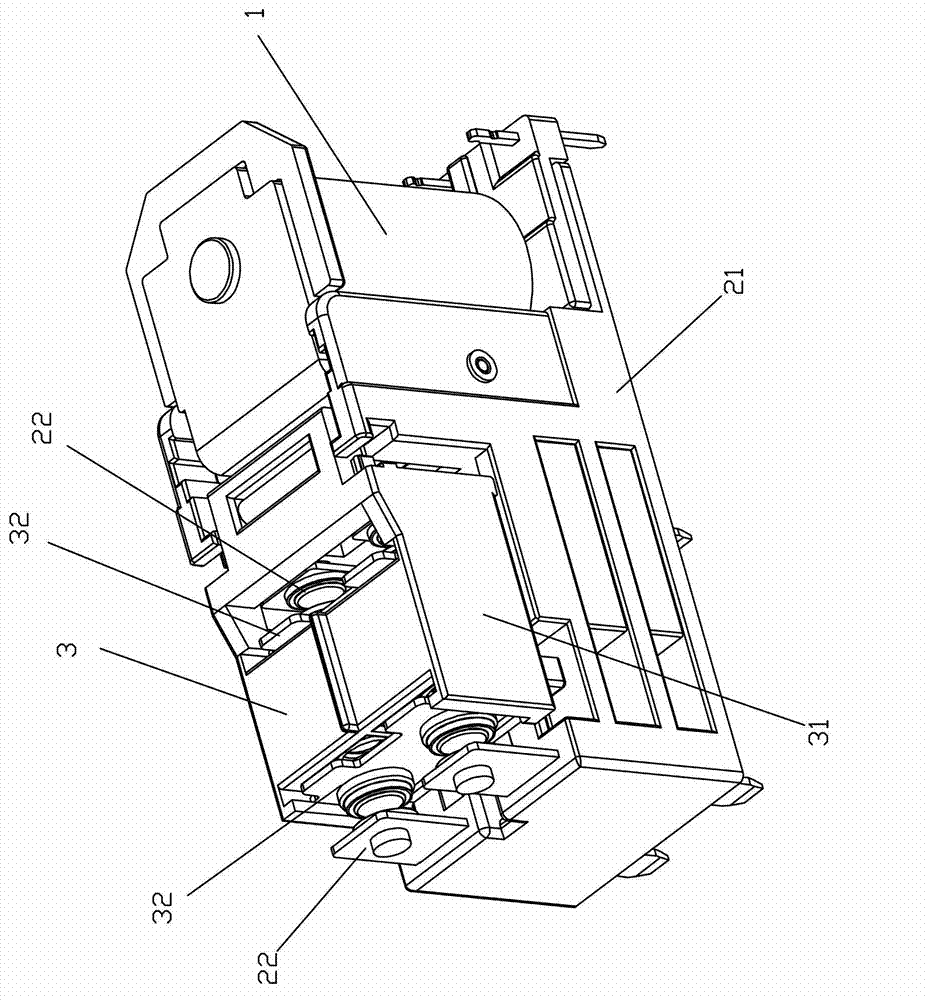

A non-reactive electromagnetic relay

ActiveCN103715025BFast actionReduce designElectromagnetic relay detailsCounterforceBiomedical engineering

The invention discloses a non-counterforce electromagnetic relay. The non-counterforce electromagnetic relay comprises a magnetic circuit part, a base, a static reed assembly, a push clamping part and a housing. The magnetic circuit part includes an armature part, a coil and a yoke. The push clamping part includes a push clamp and a contact sheet part installed on the push clamp. The contact sheet part includes a contact sheet installed on the push clamp. The armature part is movably clamped with the push clamp. The magnetic circuit part generates magnetic forces to drive the push clamp to move back and forth no matter a relay is in a setting state or a resetting state. A clamping hook is arranged at the bottom of the push clamp. A first clamping groove is arranged in the base correspondingly. The push clamp is clamped on the base through the cooperation between the first clamping groove and the clamping hook. The non-counterforce electromagnetic relay not only has the advantages of simple structure, stable performance and low cost, but also can guarantee the smoothness and stability of the high-speed motion of the push clamp on the base and guarantee that the contact sheet cannot slip off from the push clamp in the process of the high-speed motion of the push clamp.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

Non-counterforce electromagnetic relay

The invention discloses a non-counterforce electromagnetic relay. The non-counterforce electromagnetic relay comprises a magnetic circuit part, a base, a static reed assembly, a push clamping part and a housing. The magnetic circuit part includes an armature part, a coil and a yoke. The push clamping part includes a push clamp and a contact sheet part installed on the push clamp. The contact sheet part includes a contact sheet installed on the push clamp. The armature part is movably clamped with the push clamp. The magnetic circuit part generates magnetic forces to drive the push clamp to move back and forth no matter a relay is in a setting state or a resetting state. A clamping hook is arranged at the bottom of the push clamp. A first clamping groove is arranged in the base correspondingly. The push clamp is clamped on the base through the cooperation between the first clamping groove and the clamping hook. The non-counterforce electromagnetic relay not only has the advantages of simple structure, stable performance and low cost, but also can guarantee the smoothness and stability of the high-speed motion of the push clamp on the base and guarantee that the contact sheet cannot slip off from the push clamp in the process of the high-speed motion of the push clamp.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

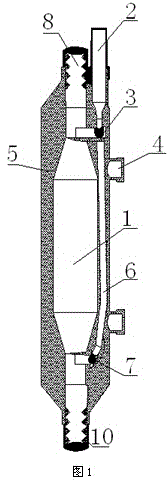

Sealing joint for transfer between cable and signal cable and manufacturing method thereof

InactiveCN104868435AAvoid affecting lifeEffective waterproofCable junctionsApparatus for joining/termination cablesCoaxial cableEngineering

The invention discloses a sealing joint for transfer between a cable and a signal cable, which comprises a stress tube, a coaxial cable joint, a waterproof system, and an electrode, wherein cross sections at two ends of the stress tube are smaller than the cross section in the middle part; a first protection layer is arranged around the stress tube; the coaxial cable joint is arranged at the outer side of the first protection layer and located at one end of the stress tube; the coaxial cable joint and the stress tube are connected via the electrode; and the waterproof system sleeves the stress tube and the coaxial cable joint. The invention also discloses a sealing joint manufacturing method. in order to solve defects that in the condition of force pulling in the prior art, intrusion of a foreign body happens due to looseness, an arcing phenomenon thus happens between cables in the stress tube, and electric energy transmission is influenced, a new connection structure is designed, separation between the cable and the sealing joint under the pulling force can be effectively avoided, the arcing phenomenon due to immersion of conductive liquid can be prevented from happening, and safety accidents can be prevented from happening.

Owner:张维秀

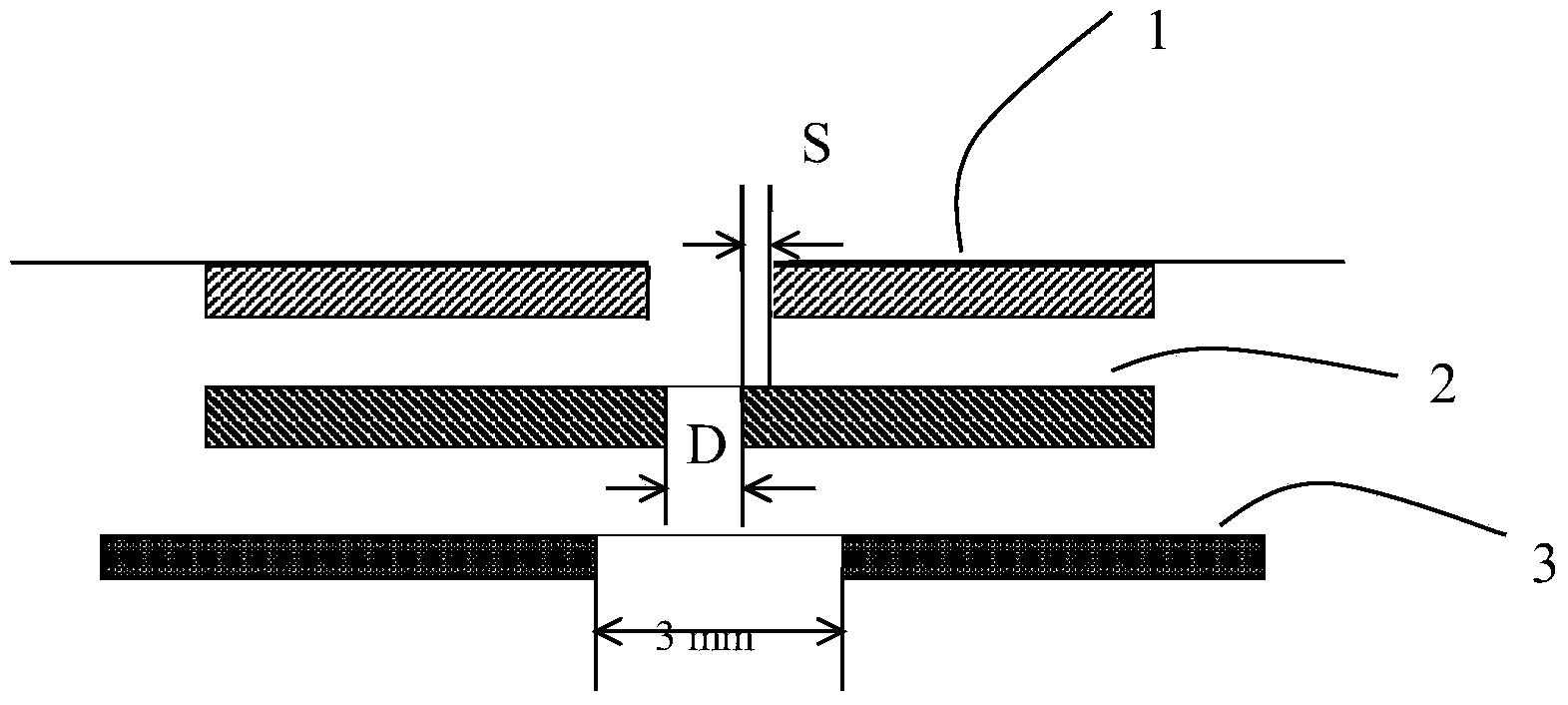

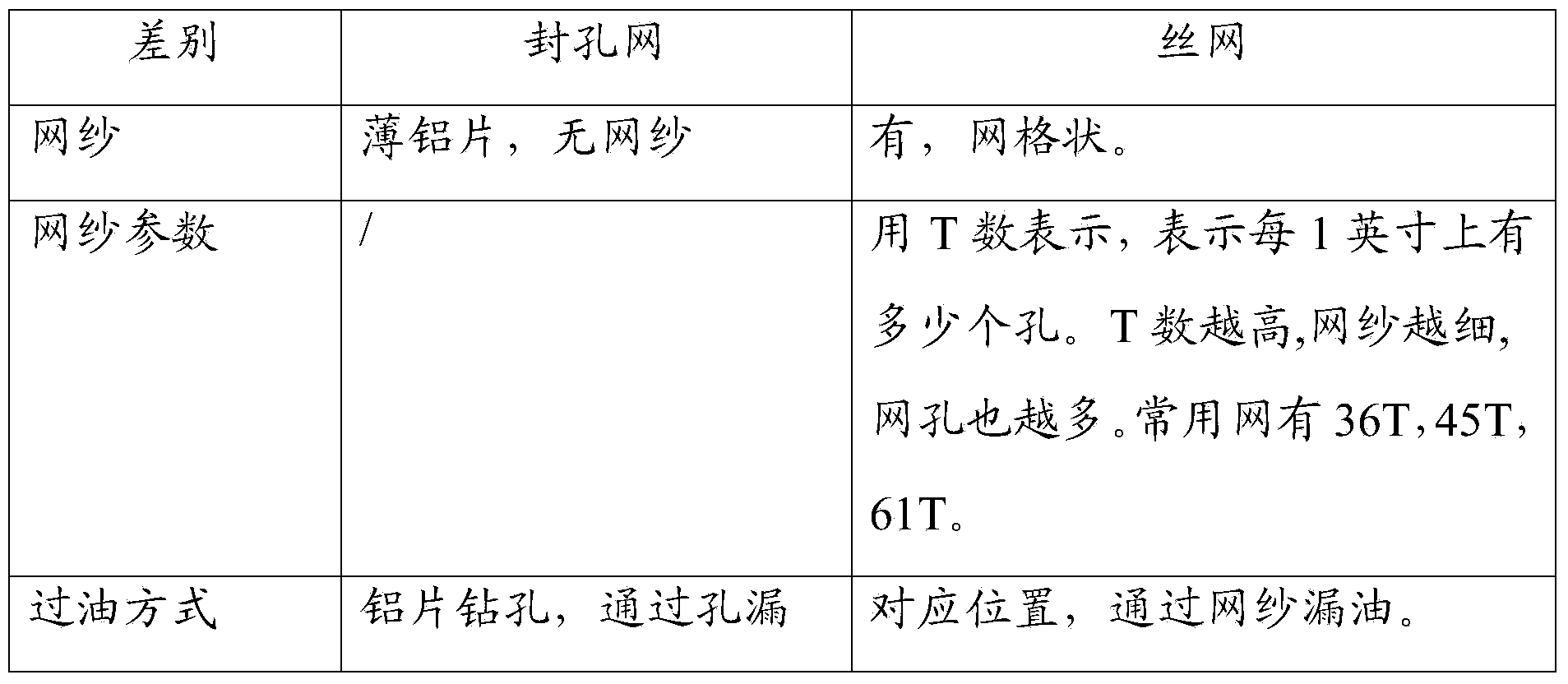

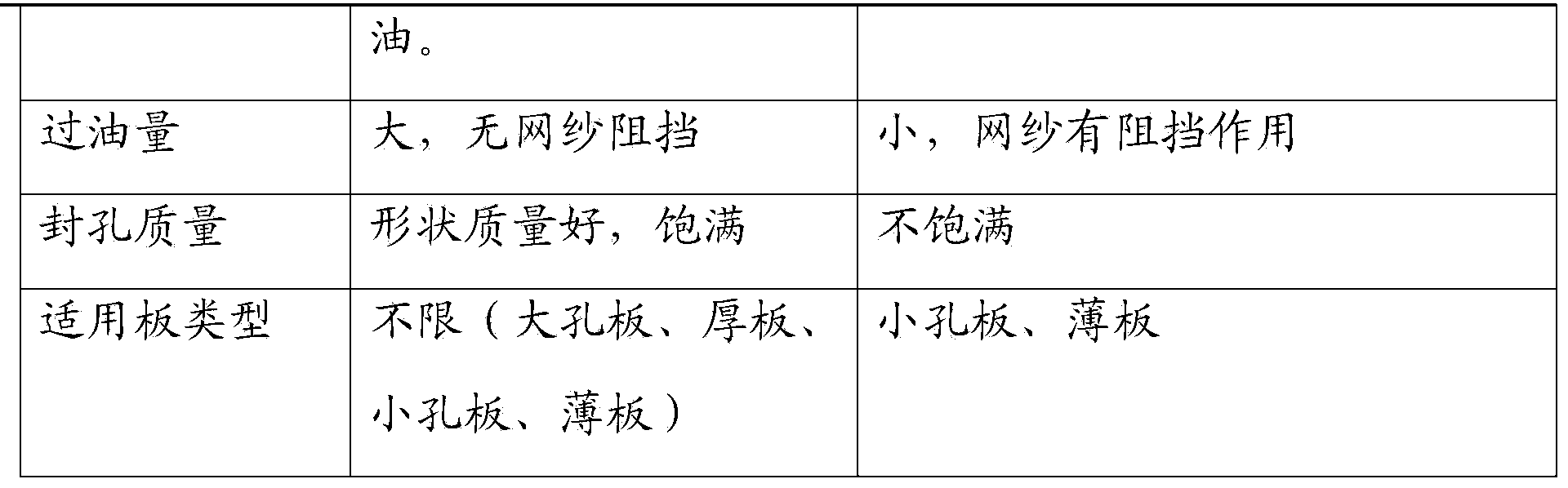

Printed circuit board and green-oil hole sealing process

ActiveCN104394654AAvoid deformationTimely exclusionPrinted circuit aspectsPrinted circuit secondary treatmentEngineeringElectrical performance

The invention discloses a printed circuit board and a green-oil hole sealing process. The green-oil hole sealing process comprises the following steps: manufacturing of a hole sealing base plate, manufacturing of a hole sealing net, fore treatment, hole sealing and solidification. According to the invention, the hole sealing net (rigid net, the material can be aluminum sheets, stainless steel sheets and the like) is employed to replace a conventional silk net, and compared to the silk net, the oil screening amount is large, the hole sealing quality is good and full, and the process is suitable for plates of various types. Besides, the hole sealing base plate is also cushioned below a hole sealing plate, and boring is carried out on an area, which is opposite to the hole sealing position of the hole sealing plate, on the hole sealing base plate, such that air in a hole during hole sealing can be timely exhausted, and the electrical performance of the circuit board is prevented from being affected due to a bubble formed in the hole. Through manufacture of the hole sealing base plate and the hole sealing net, coupled with proper technical parameters, the requirements of a client for hole sealing depth and quality can be well satisfied.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

High-temperature-resistant hot-melt self-adhesive enameled wire

PendingCN113270225AImprove electrical performanceAffect electrical performanceFireproof paintsMicaHeat resistanceCoating

The invention belongs to the technical field of enameled wires, and particularly relates to a high-temperature-resistant hot-melting self-adhesion enameled wire. The enameled wire comprises a wire core, a bottom coating and a surface layer. The surface of the wire core is coated with the bottom coating; the surface layer is coated on the surface of the bottom coating layer; mica powder is mixed in the bottom coating, and the mica powder is made of sericite; the particle size of the mica powder is 600 to 700 meshes; the volume fraction of the mica powder in the bottom coating is 8-12%; the prepared enameled wire is good in heat resistance, the coating is not prone to damage, and meanwhile the enameled wire is high in strength and not prone to breakage.

Owner:苏浩文

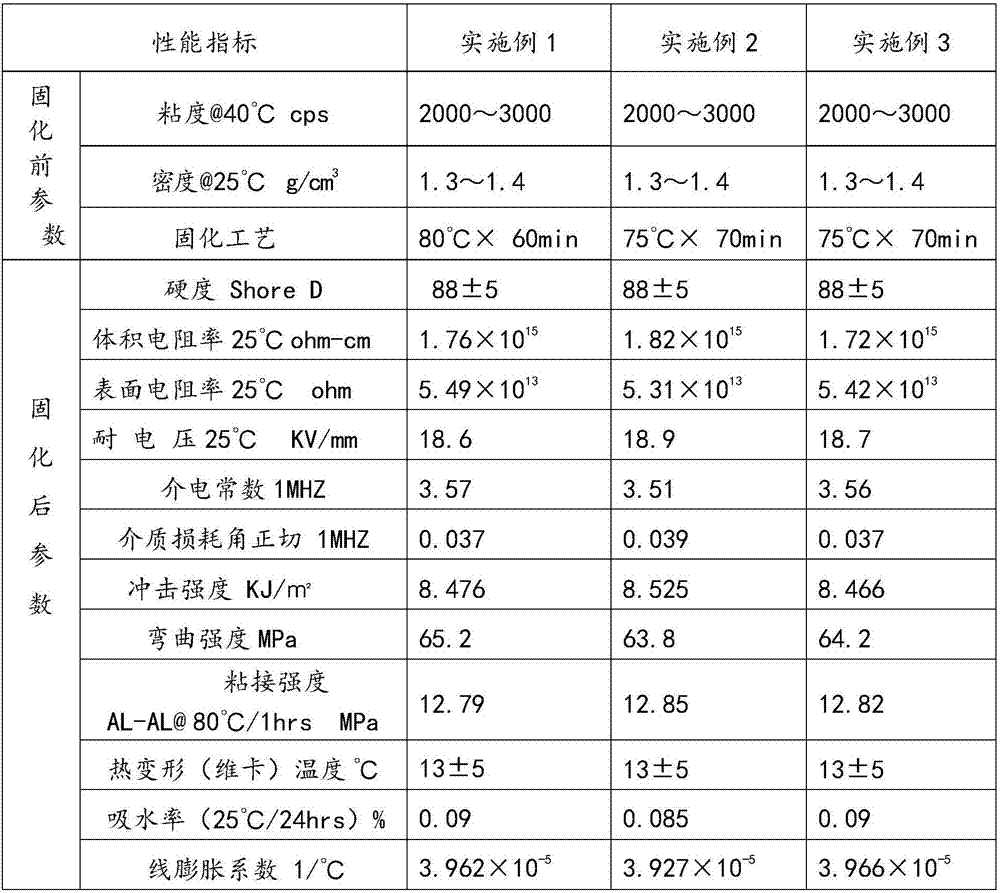

Single-liquid type low-temperature cured special glue for temperature fuse and preparation method thereof

InactiveCN107974224AAffect electrical performanceLow curing temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesLow temperature curingElectrical performance

The invention provides a single-liquid type low-temperature cured special glue for a temperature fuse and a preparation method thereof. The special glue is prepared from the following components in parts by weight: 40-50 parts of bisphenol A type epoxy resin, 5-10 parts of flexible type epoxy resin, 3-8 parts of pigment, 0.5-2 parts of additives, 15-25 parts of curing agents and 20-30 parts of filling. The special glue is cured at low temperature, and does not influence the electrical performance of the fuse due to curing under heating in production process of the fuse. The special glue has the advantages of high flame resistance, low volatility, and high adhesion property.

Owner:富邦(厦门)新材料有限公司

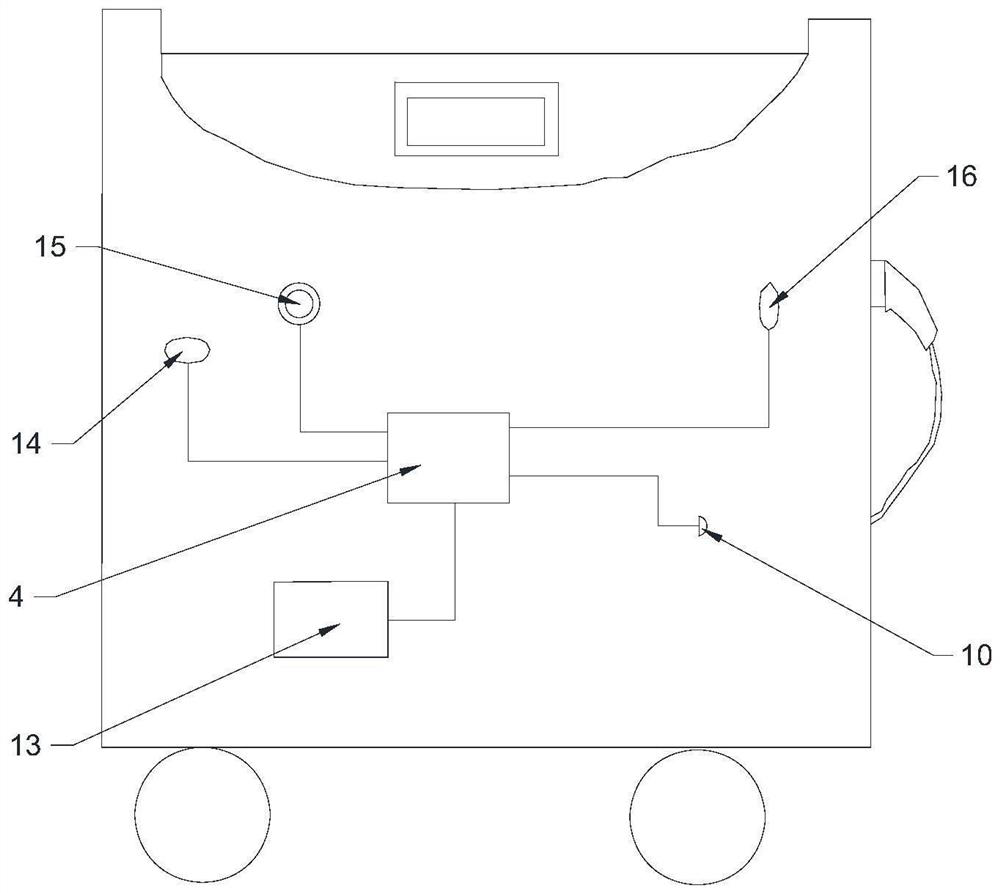

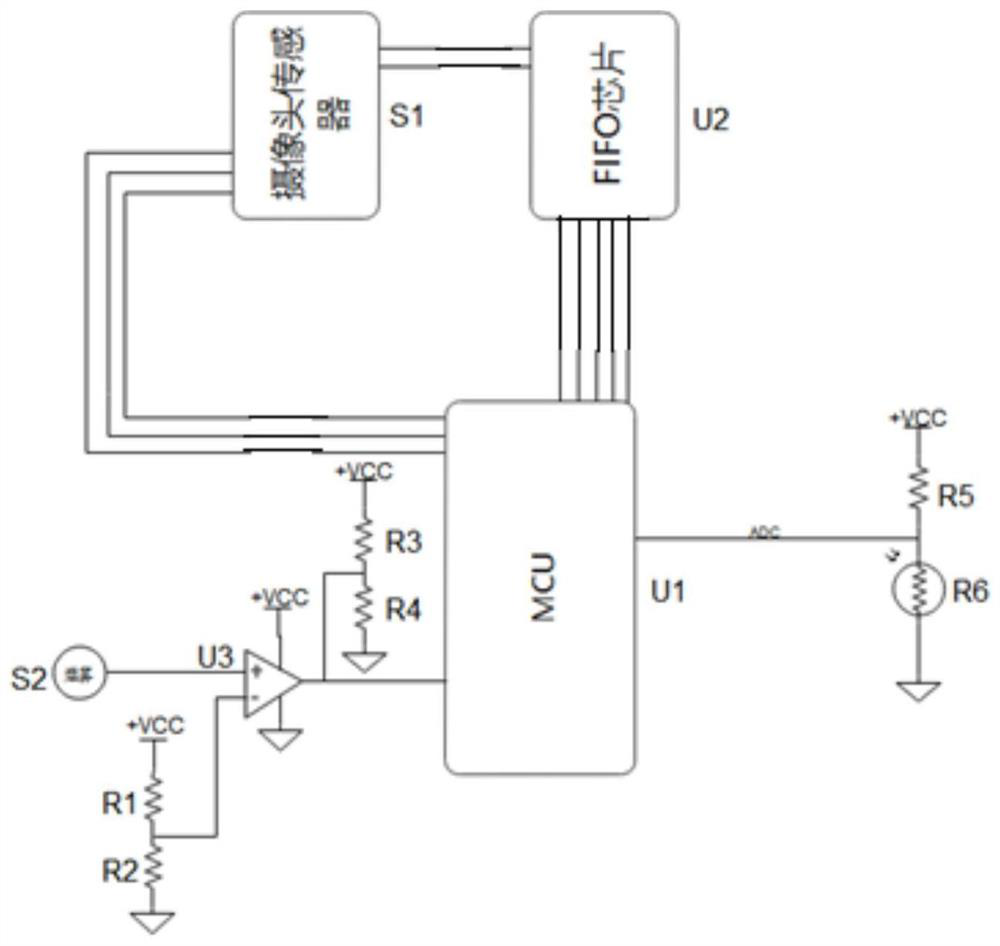

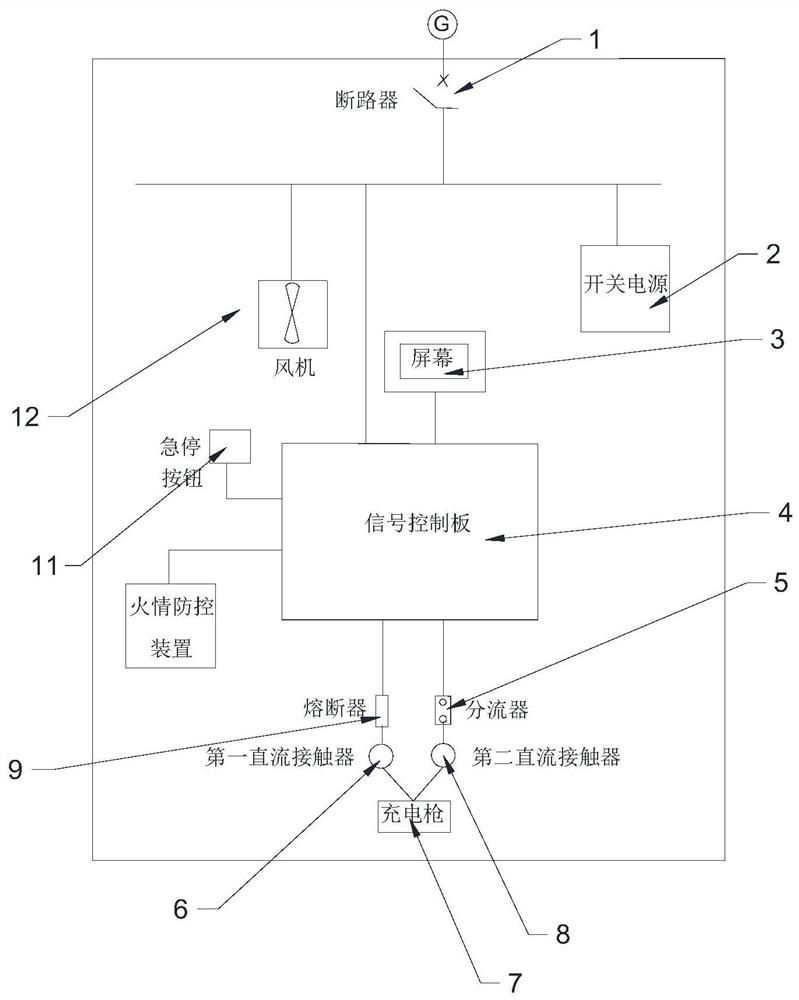

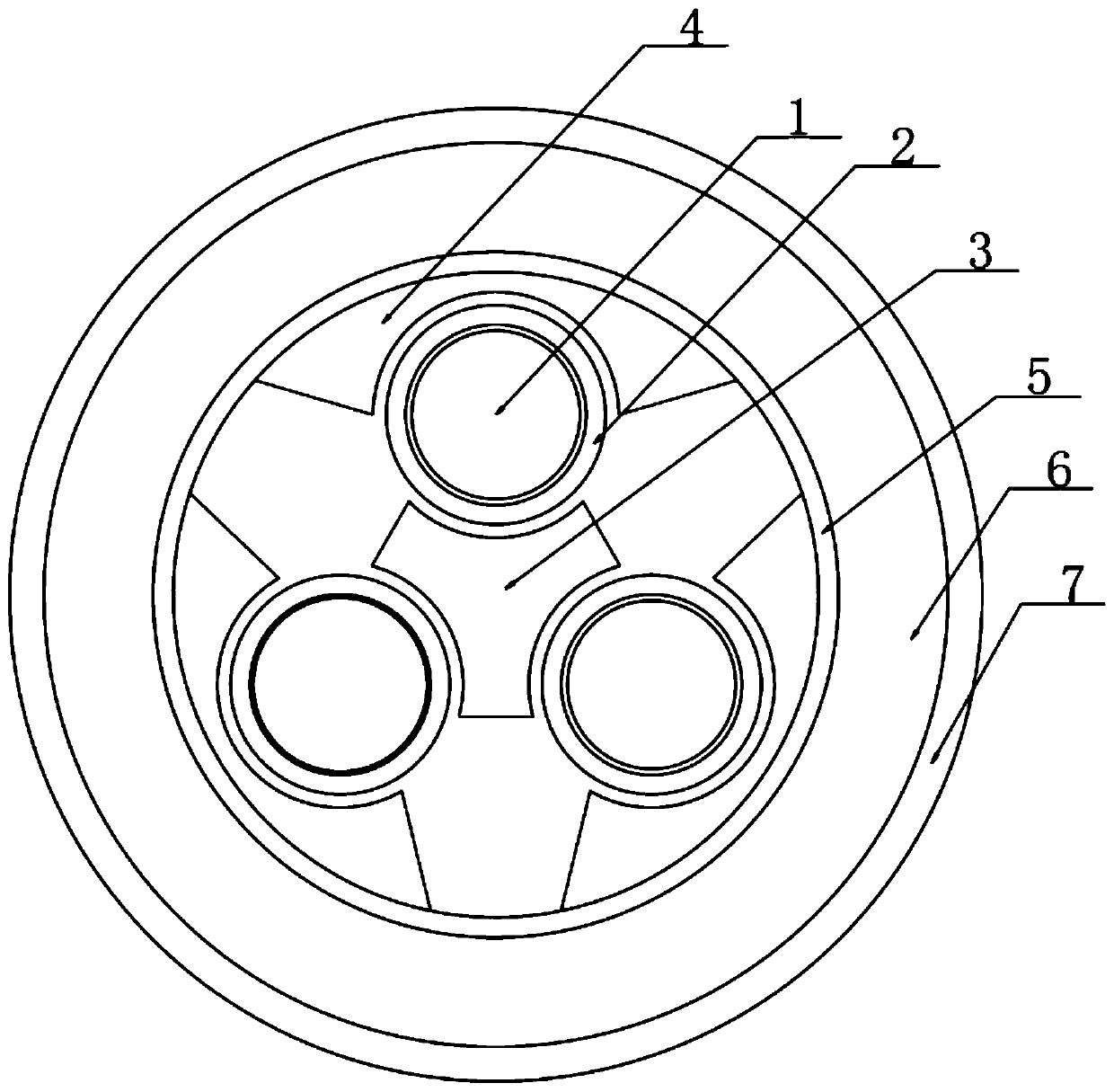

Fire prevention and control device for V2G direct-current charging pile

PendingCN112274818AAvoid damageAffect electrical performanceCharging stationsFire rescueEnvironmental engineeringSmoke Emission

The invention discloses a fire prevention and control device for a V2G direct-current charging pile. The fire prevention and control device for the V2G direct-current charging pile comprises a case arranged in the V2G direct-current charging pile, wherein a temperature sensor used for detecting real-time temperature information, a smoke sensor unit used for detecting real-time smoke concentrationinformation, a camera unit used for shooting real-time fire information, and a fire extinguishing unit used for releasing a fire extinguishing agent and containing the fire extinguishing agent are arranged on the case; a fire extinguishing agent recovery unit used for sucking the fire extinguishing agent is arranged in the case; and the temperature sensor, the smoke sensor unit, the camera unit, the fire extinguishing unit and the fire extinguishing agent recovery unit are all electrically connected with a signal control panel in a pile body of the V2G direct-current charging pile. The invention aims to provide the fire prevention and control device for the V2G direct-current charging pile which can be installed in the V2G direct-current charging pile, three fire prevention detection methods are provided, information interaction with the V2G direct-current charging pile can be carried out, and when a fire occurs, the fire can be eliminated.

Owner:SGCC SMART ENERGY & ELECTRIC TRANSPORTATION TECH INNOVATION CENT (SUZHOU) CO LTD

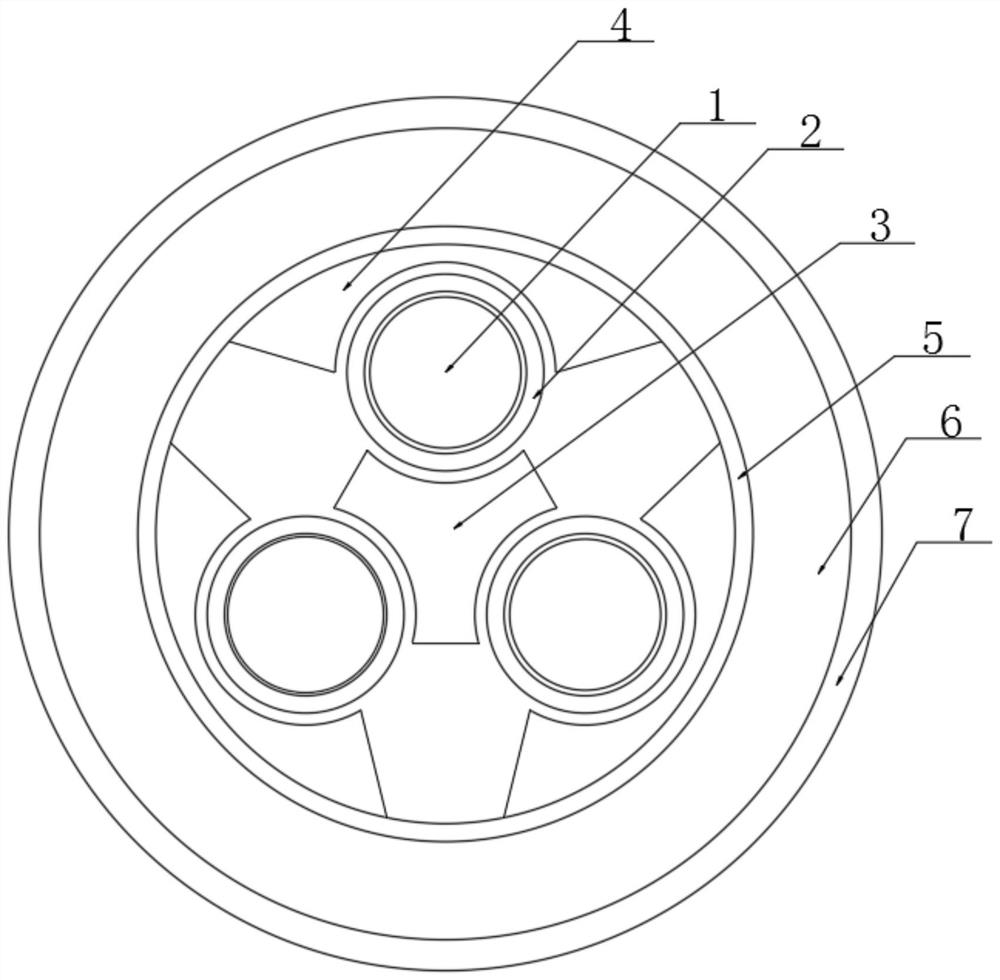

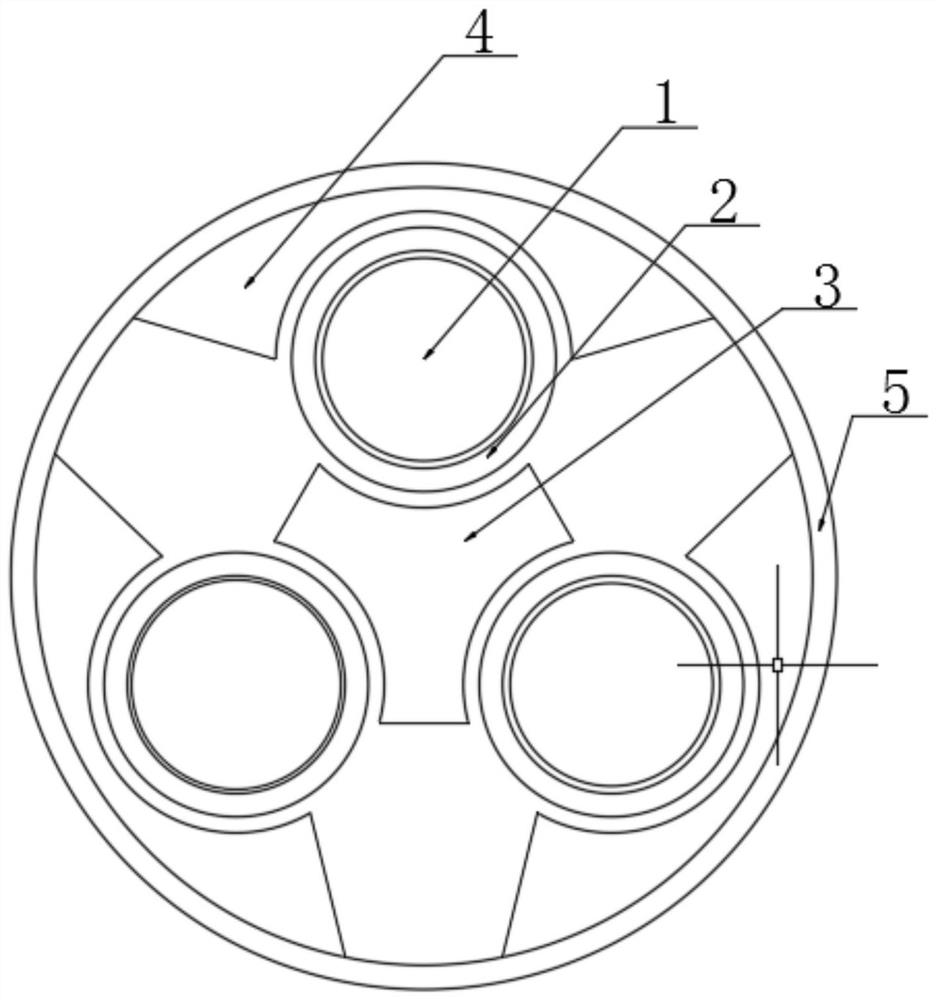

Detection cable

ActiveCN109830333AFor the purpose of high temperature resistanceSimple anti-interference abilityInsulated cablesInsulated conductorsElectrical conductorThermal expansion

The invention discloses a detection cable and in particular relates to the cable field. The detection cable comprises a conductor core, wherein the surface of the conductor core is fixedly connected with a conductor shielding layer; the surface of the conductor shielding layer is movably connected to a stopping block and a positioning block; and the surface of the positioning block is fixedly connected with a fixing layer. The conductor core can be fixed through the stopping block and the positioning block. Thus, the conductor cores in a cable can be prevented from rotating relative to each other and further from causing the cable to fracture and affecting the electrical performance of the cable. A thermal expansion block is expanded by heat and pushes a fire extinguishing ball to make thefire extinguishing ball in a compressed state. When the cable is fired and burns out the fire extinguishing ball, the compressed fire extinguishing ball eject the carbon dioxide to extinguish the fire, thereby achieving a purpose of high temperature resistance. A first reinforcing layer and a second reinforcing layer can protect the steel wire of an outer armored layer against serious wear, thereby prolonging the service life of the cable.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

Printed circuit board and method for manufacturing printed circuit board

ActiveCN104661427BAffect electrical performanceElectrical connection printed elementsMultilayer circuit manufactureJoint surfacePrinted circuit board

The invention provides a printed circuit board. The printed circuit board comprises multiple daughter boards, wherein the daughter boards comprise a first daughter board located on the outermost side of the printed circuit board; at least one first through hole is formed in the first daughter board and penetrates through back drilling surface and a compression joint surface of the first daughter board; the wall of the first through hole is plated with a conductive metal layer; a first step hole is formed in the first daughter board in a back drilling manner and is communicated with the first through hole; the projection of the first step hole on the back drilling surface of the first daughter board covers the projection of the first through hole on the back drilling surface of the first daughter board; the first step hole is separated from other holes formed in the first daughter board. The invention further provides a manufacturing method of the printed circuit board. According to the printed circuit board and the method, the step hole is formed, so that accommodation space for accommodating a fluid is formed, and the fluid can be prevented from flowing into a blind hole of the printed circuit board.

Owner:HUAWEI TECH CO LTD

a detection cable

ActiveCN109830333BFor the purpose of high temperature resistanceSimple anti-interference abilityInsulated cablesInsulated conductorsThermal dilatationElectrical conductor

The invention discloses a detection cable and in particular relates to the cable field. The detection cable comprises a conductor core, wherein the surface of the conductor core is fixedly connected with a conductor shielding layer; the surface of the conductor shielding layer is movably connected to a stopping block and a positioning block; and the surface of the positioning block is fixedly connected with a fixing layer. The conductor core can be fixed through the stopping block and the positioning block. Thus, the conductor cores in a cable can be prevented from rotating relative to each other and further from causing the cable to fracture and affecting the electrical performance of the cable. A thermal expansion block is expanded by heat and pushes a fire extinguishing ball to make thefire extinguishing ball in a compressed state. When the cable is fired and burns out the fire extinguishing ball, the compressed fire extinguishing ball eject the carbon dioxide to extinguish the fire, thereby achieving a purpose of high temperature resistance. A first reinforcing layer and a second reinforcing layer can protect the steel wire of an outer armored layer against serious wear, thereby prolonging the service life of the cable.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

an electrical connector

ActiveCN105390877BAffect electrical performanceCoupling device detailsButt jointElectrical performance

The invention discloses an electric connector which comprises an inner insulated casing, an outer insulated casing, first terminals and second terminals. The inner insulated casing comprises a base part and a tongue plate; the outer insulated casing wraps the external surface of the inner insulated casing, and includes a butt-joint portion which extends to the front end of the tongue plate; each first terminal comprises a first connection portion, a first front portion and a first back portion; and the second terminal comprises a second connection portion, a second front portion and a second back portion, both the second connection portion and the first connection portion are arranged in the base part, the first back portion and the second back portion are arranged at two surfaces, opposite to each other, of the tongue plate respectively, the first front portion and the second front portion are arranged at two surfaces, opposite to each other, of the butt-joint portion respectively, and the front end of the butt-joint portion is protruded out of the first and second front portions. When the electric connector is plugged with another connector, terminals of the other connector are guided to enter the tongue plate smoothly, and the other connector is prevented from jacking up the first or second front portion directly, causing deformation of the first or second portion, and influencing the electrical performance of the electric connector.

Owner:SHENZHEN DEREN ELECTRONICS

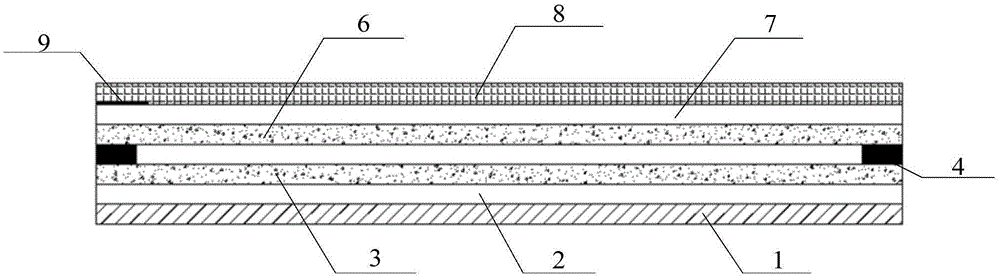

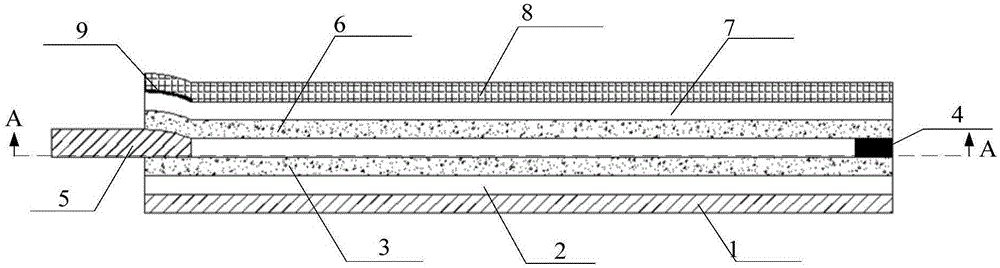

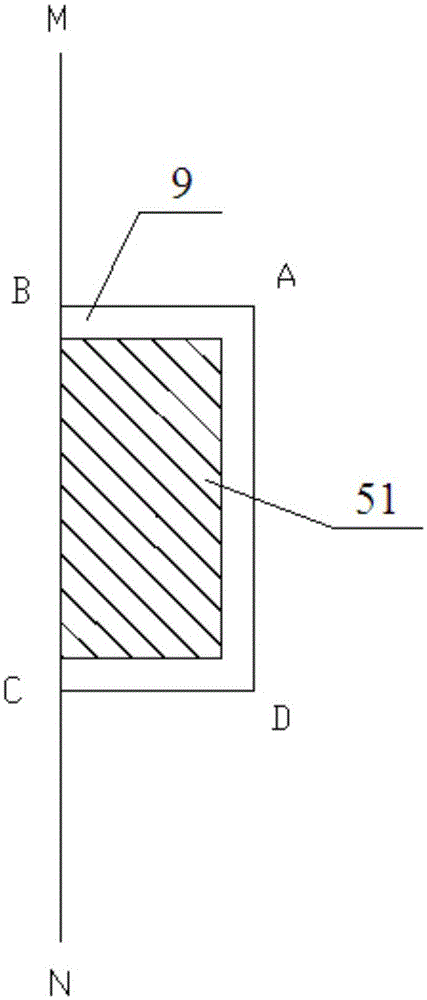

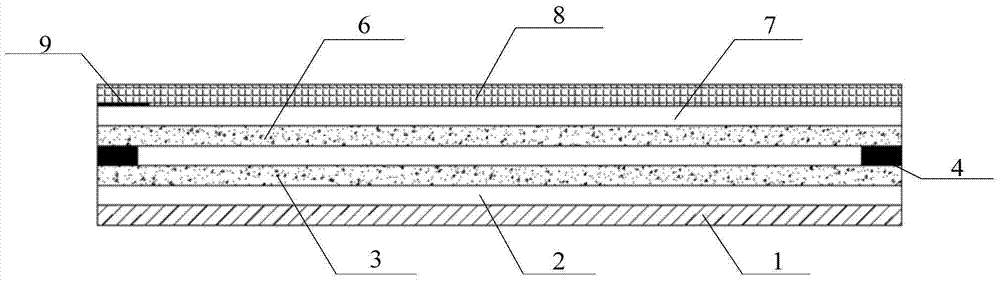

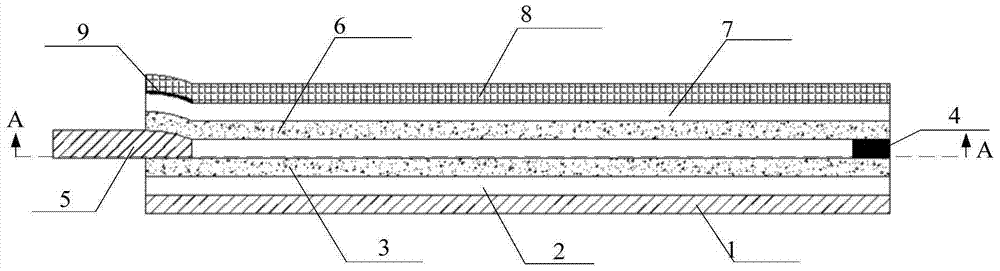

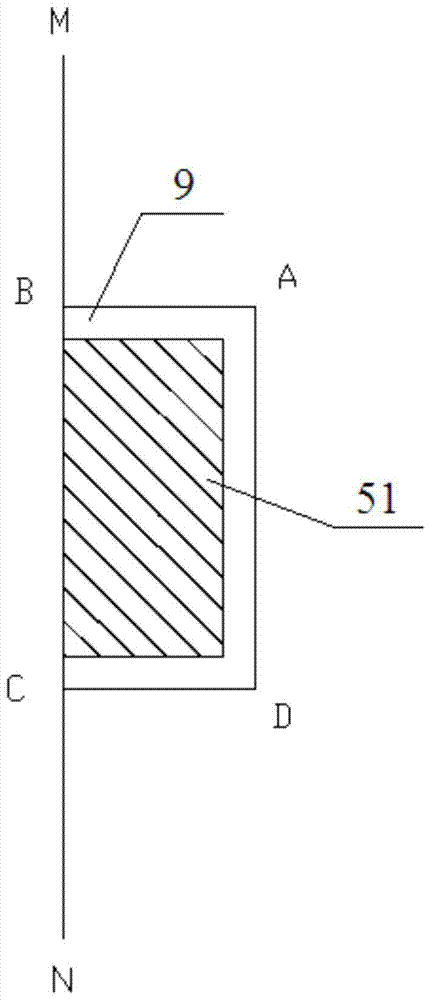

Flat-touch screen and manufacturing method thereof

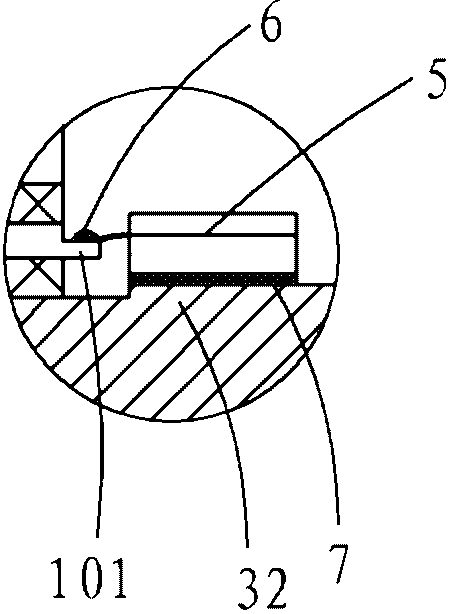

ActiveCN105138174AAvoid air bubblesAvoid electrical performanceInput/output processes for data processingAdhesiveEngineering

The invention provides a flat-touch screen. The flat-touch screen comprises a flexible circuit board 5, a glass substrate 1, a lower-layer optical adhesive layer 2, a lower-layer conducting layer 3, a double faced adhesive tape 4, an upper-layer conducting layer 6, an upper-layer optical adhesive layer 7 and a cover plate 8, wherein the glass substrate 1, the lower-layer optical adhesive layer 2, the lower-layer conducting layer 3, the double faced adhesive tape 4, the upper-layer conducting layer 6, the upper-layer optical adhesive layer 7 and the cover plate 8 are sequentially arranged in a stacked mode. The flexible circuit board 5 is electrically connected with the lower-layer conducting layer 3 and the upper-layer conducting layer 6 respectively and is arranged between the lower-layer conducting layer 3 and the upper-layer conducting layer 6. An electronic coating 9 is arranged between the upper-layer optical adhesive layer 7 and the cover plate 8 and used for isolating the upper-layer optical adhesive layer 7 from the cover plate 8, so that when the flexible circuit board 5 is connected with the lower-layer conducting layer 3 and the upper-layer conducting layer 6, the upper-layer optical adhesive layer 7 is only subjected to the tensile force of the upper-layer conducting layer 6, the phenomenon that air bubbles are produced due to excessive tensile force deformation between the upper-layer conducting layer 6 and the upper-layer optical adhesive layer 7 is avoided, and the electrical performance of the flat-touch screen is prevented from being influenced due to frequent pressing conducted on the flexible circuit board 5.

Owner:HUANGSHI RAECE TECH

Flat touch screen and method of making the same

ActiveCN105138174BAffect electrical performanceAvoid it happening againInput/output processes for data processingFlexible circuitsOptical coating

The present invention provides a flat touch screen, comprising a flexible circuit board 5 and a glass substrate 1, a lower optical adhesive layer 2, a lower conductive layer 3, a double-sided adhesive 4, an upper conductive layer 6, an upper optical adhesive layer 7 and The cover plate 8; the flexible circuit board 4 is electrically connected to the lower conductive layer 3 and the upper conductive layer 6 respectively and is arranged between them; an electronic coating 9 is provided between the upper optical adhesive layer 7 and the cover plate 8, and the electronic coating Layer 9 is located right above the flexible circuit board 5 . In the present invention, by providing an electronic coating 9 between the upper optical adhesive layer 7 and the cover plate 8, the upper optical adhesive layer 7 and the cover plate 8 are isolated, so that when the flexible circuit board 3 is connected to the lower conductive layer 3 and the upper conductive layer 6 , the upper optical adhesive layer 7 is only subjected to the pulling force of the upper conductive layer 6, which avoids the generation of air bubbles between the upper conductive layer 6 and the upper optical adhesive layer 7 due to excessive tension deformation, and prevents the frequent pressing of the flexible circuit board 5 from affecting the pure Electrical performance of flat touch screens.

Owner:HUANGSHI RAECE TECH

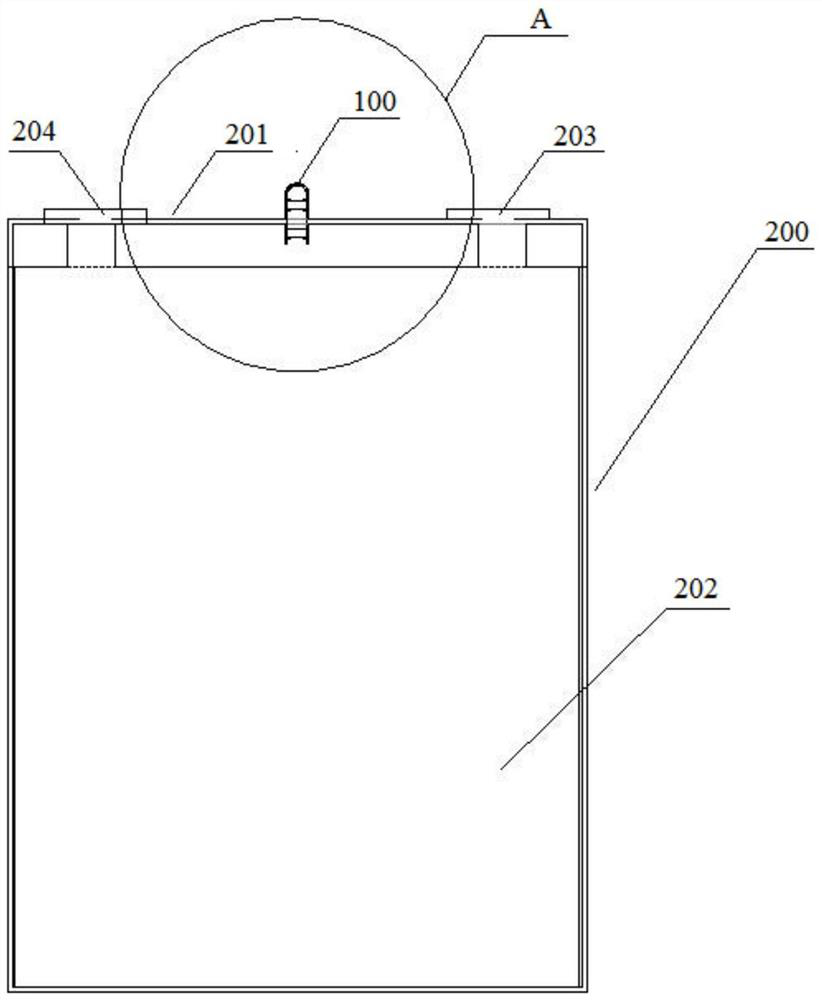

Hard case battery and its one-way vent valve

ActiveCN107195835BReduce volumeEasy exhaust operationFinal product manufactureSmall-sized cells cases/jacketsExhaust valveMechanical engineering

The invention discloses a one-way exhaust valve for a hard-shell battery, which comprises: a hollow valve body that can be installed on the battery shell of the hard-shell battery or on the top cover of the battery, the bottom end of the valve body communicates with the inside of the battery, and the valve body The top of the valve body extends out of the battery; the adsorption layer is sealed and installed in the valve body, and the adsorption layer is used to absorb the gas generated inside the battery and discharge the gas from the top of the valve body to the outside of the battery; The layer allows the gas inside the battery to exit the battery in one direction to the outside. Compared with the prior art, the one-way exhaust valve of the hard-shell battery of the present invention does not need to open the valve, and the CO generated inside the battery can be released only by the principle of adsorption and desorption. 2 , CO, CH 4 Such small molecular gases are discharged to the outside, and the exhaust operation is simple and has ideal sealing performance, which can significantly improve the service life and safety performance of hard-shell batteries. In addition, the invention also discloses a hard shell battery.

Owner:CONTEMPORARY AMPEREX TECH CO

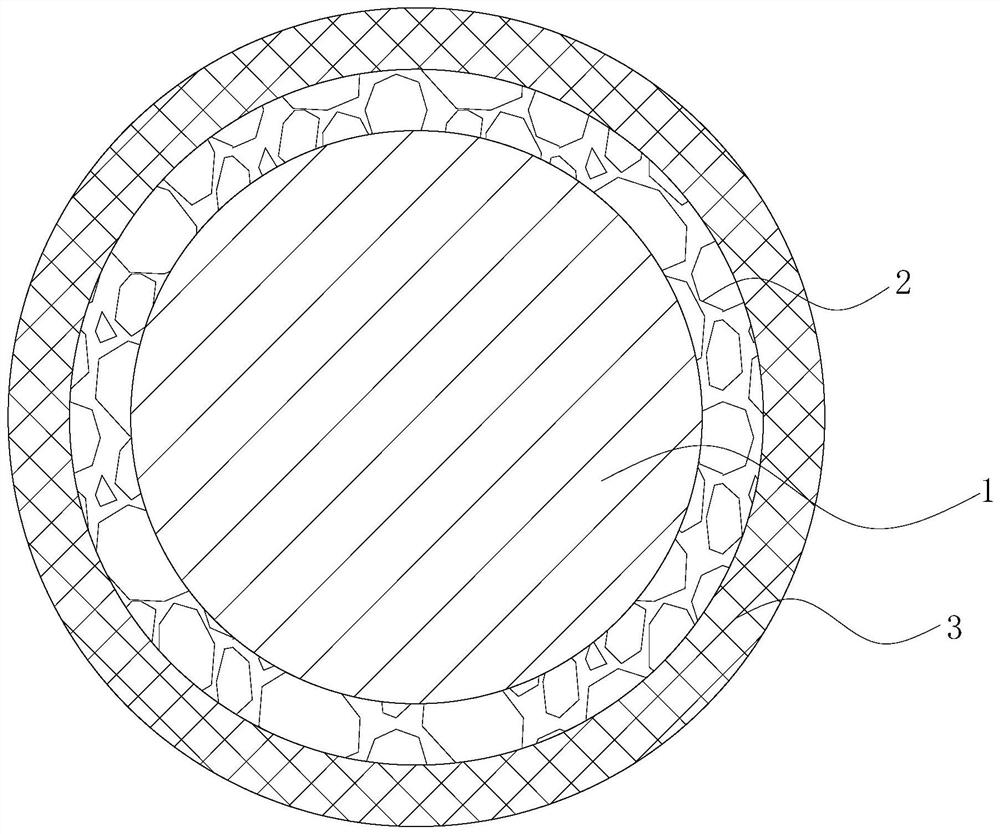

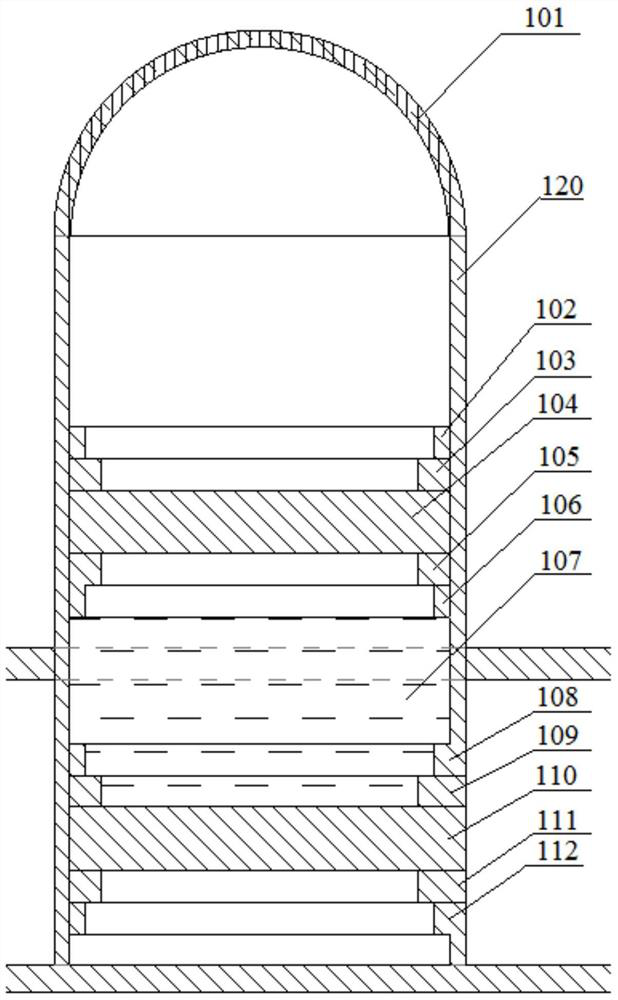

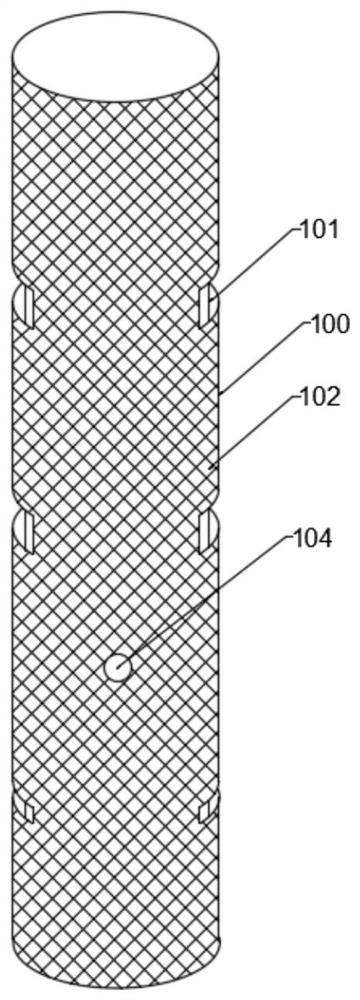

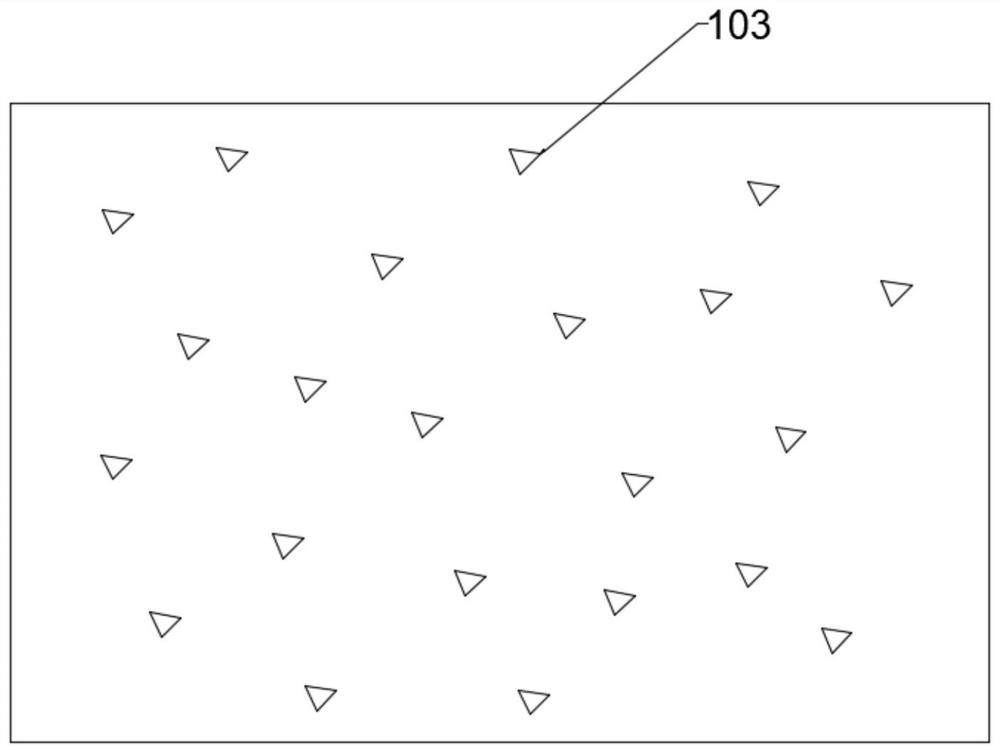

A composite insulator with alumina porcelain core rod and its manufacturing method

ActiveCN110718343BImprove bending performancePrevent slippingInsulatorsClaywaresComposite insulatorsSilicon rubber

The invention discloses an aluminum oxide porcelain core rod composite insulator, and the insulator comprises an aluminum oxide porcelain core rod and an umbrella skirt outer sleeve wrapping the aluminum oxide porcelain core rod; the aluminum oxide porcelain core rod is cylindrical, and at least one groove is formed in the side face of the aluminum oxide porcelain core rod. A reinforcing part is arranged on the outer side wall of the aluminum oxide porcelain core rod; the reinforcing part comprises grooves or bulges, and the grooves or bulges form a latticed area on the outer surface of the aluminum oxide porcelain core rod in a surrounding manner; the latticed area is provided with a plurality of triangular positioning blocks which are arranged in a disordered manner. The invention further discloses a manufacturing method of the insulator; the structure and the method are combined, so that the bending strength of the insulator is enhanced, and the binding power of the insulator and the silicone rubber umbrella skirt outer sleeve is also improved.

Owner:江西正强电瓷电器有限公司

Lamps and their cooling mechanism

ActiveCN106594690BAffect electrical performanceSolve the problem of low heat conduction efficiencyVehicle headlampsElectric circuit arrangementsEngineeringHeat sink

Owner:SHENZHEN YIKE PHOTOELECTRIC TECH

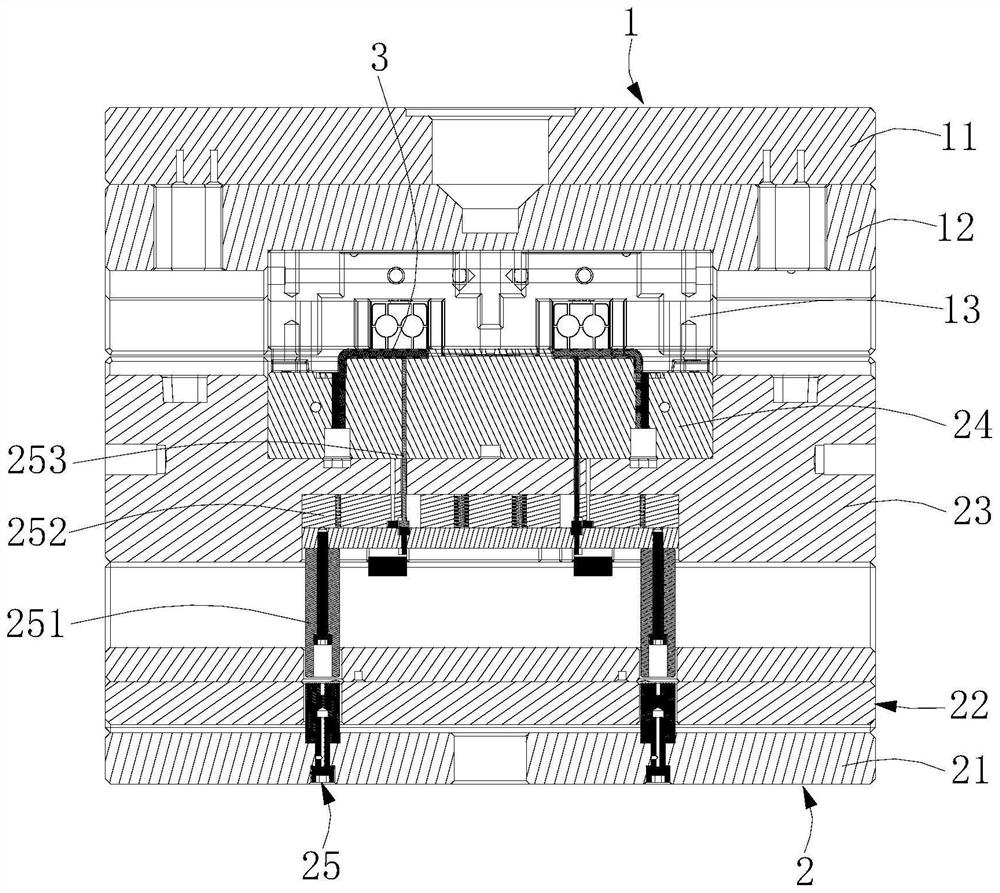

Welding system and welding method for metal parts and coaxial cables

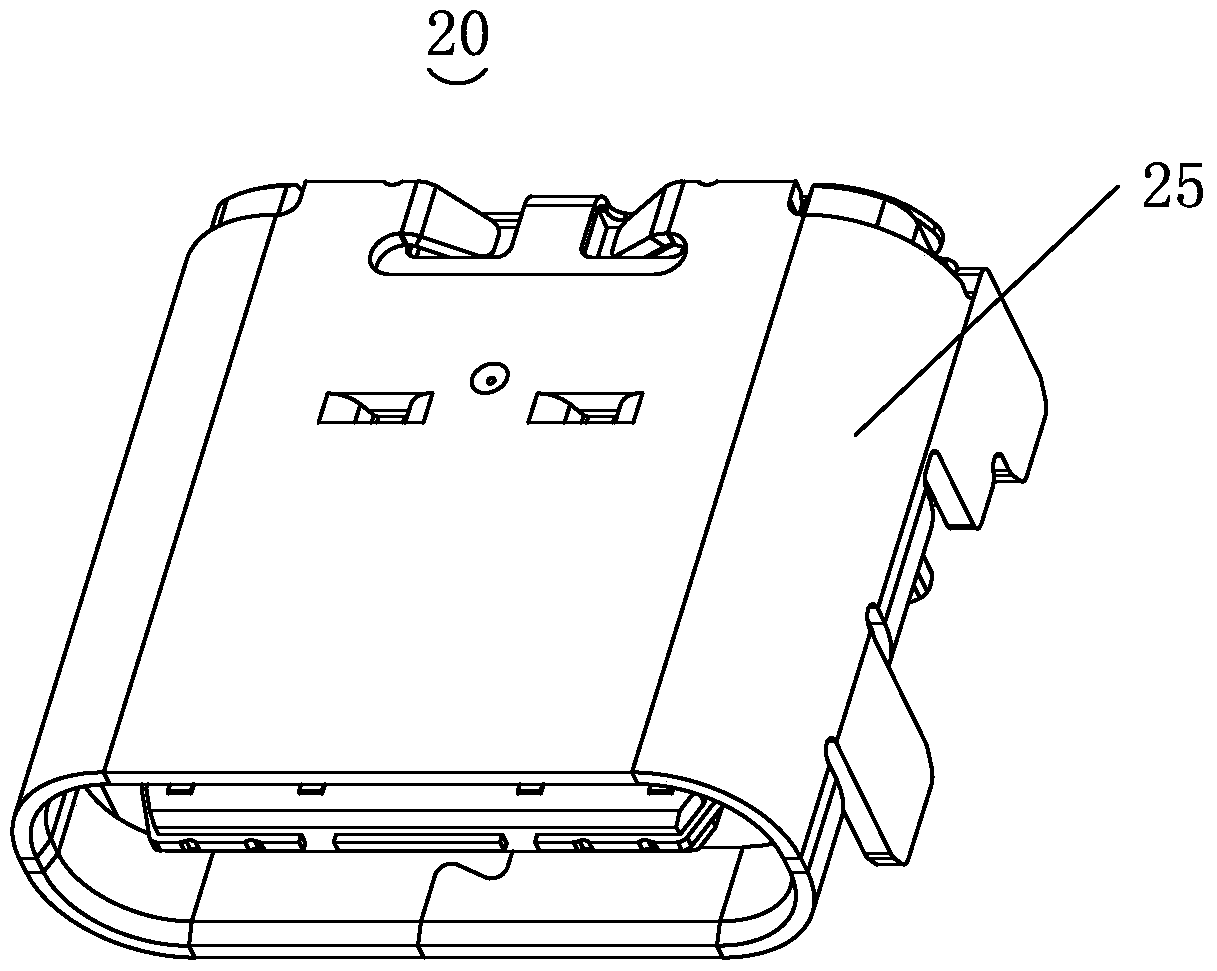

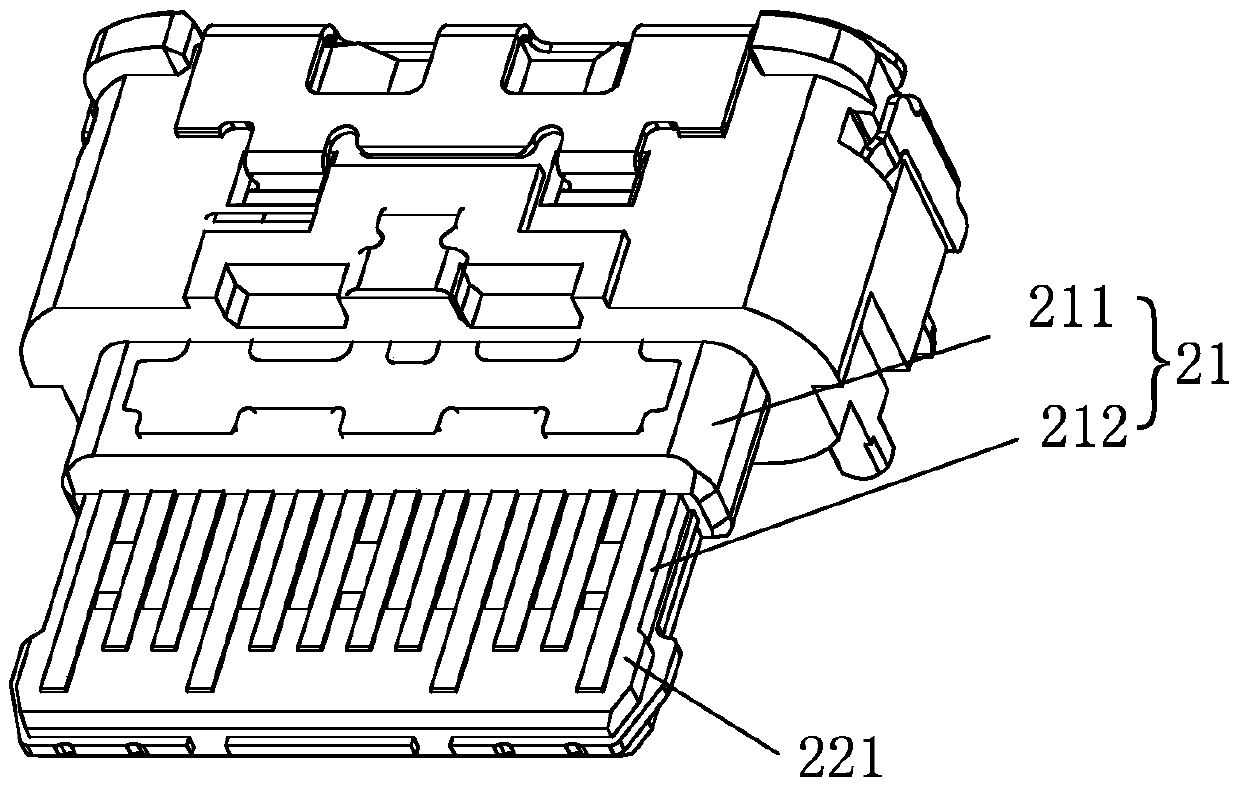

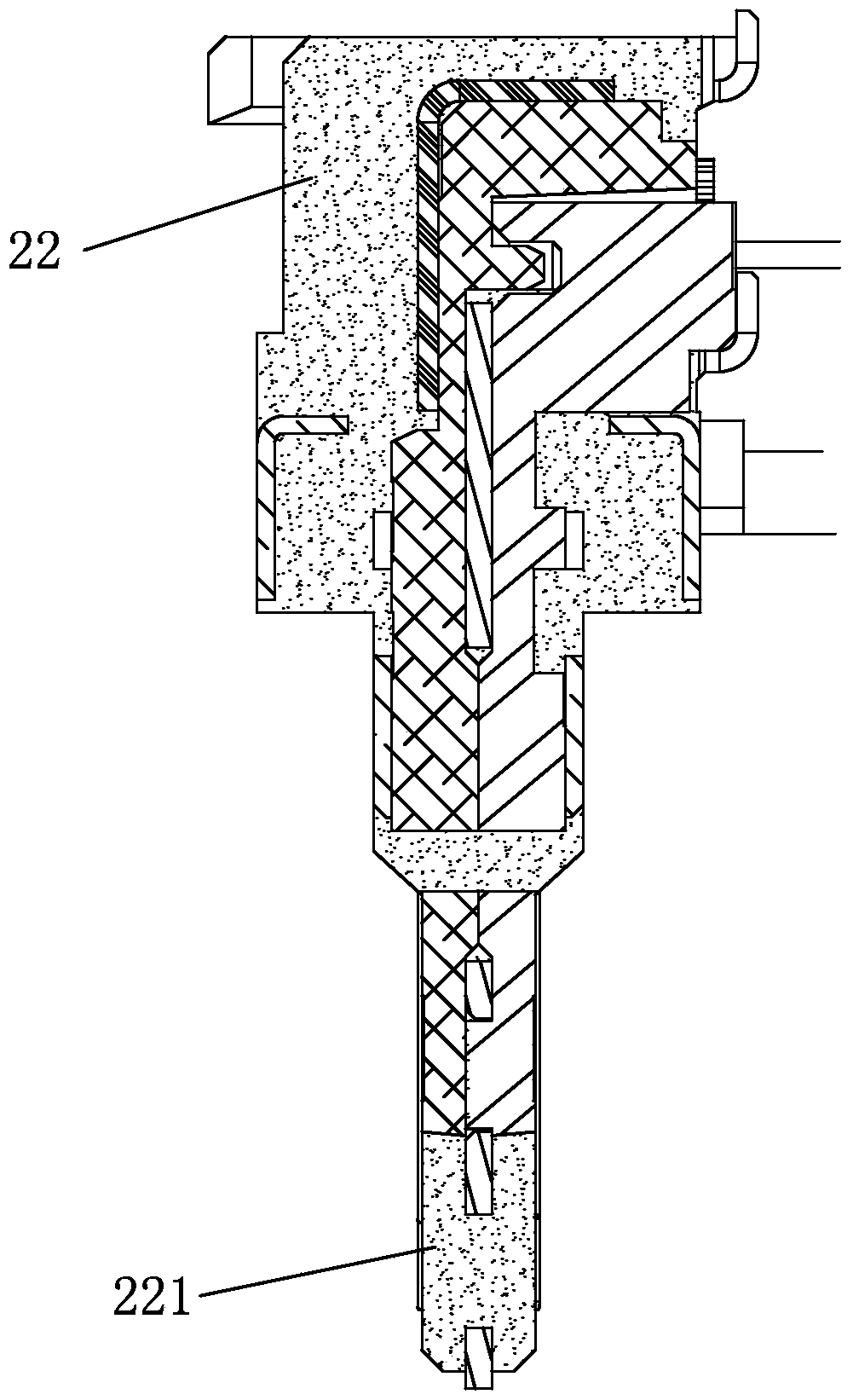

ActiveCN106112163BGood thermal conductionMeets electrical performance requirementsLine/current collector detailsHeating appliancesCoaxial cableSoldering

A welding system (2) for a metal piece (11) and a coaxial cable (12), comprising: a heating device (21) provided at a processing station and enabling the metal piece (11) or the coaxial cable (12) to enter a contact for heating; a solder feeding device (22) disposed adjacent to the heating device (21) and used for adding solder (13) to a joint of the metal piece (11) and the coaxial cable (12); and a moving and positioning device (25) used for separately clamping and transferring the metal piece (11) and the coaxial cable (12) to the processing station. The present invention also relates to a welding method for a metal piece (11) and a coaxial cable (12). The system and method can well improve the reliability and conduction rate of soldering of a metal piece and a coaxial cable, and can improve production efficiency and reducing production costs.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +2

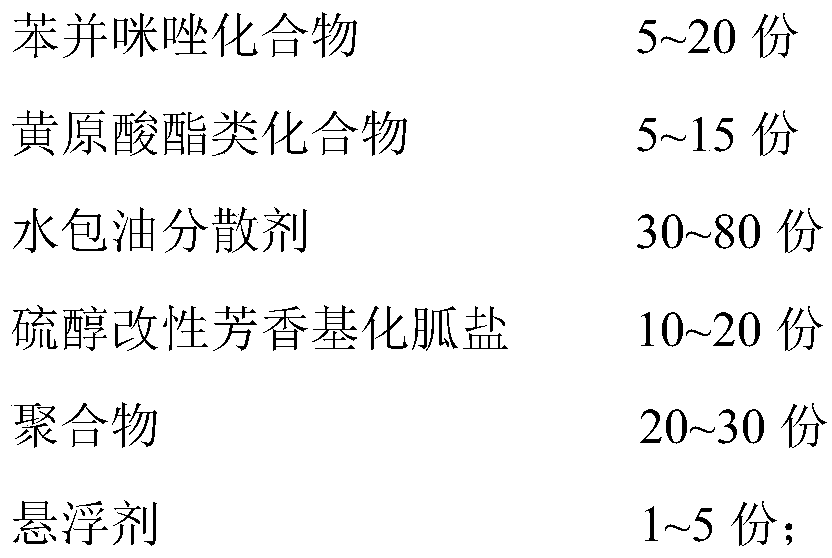

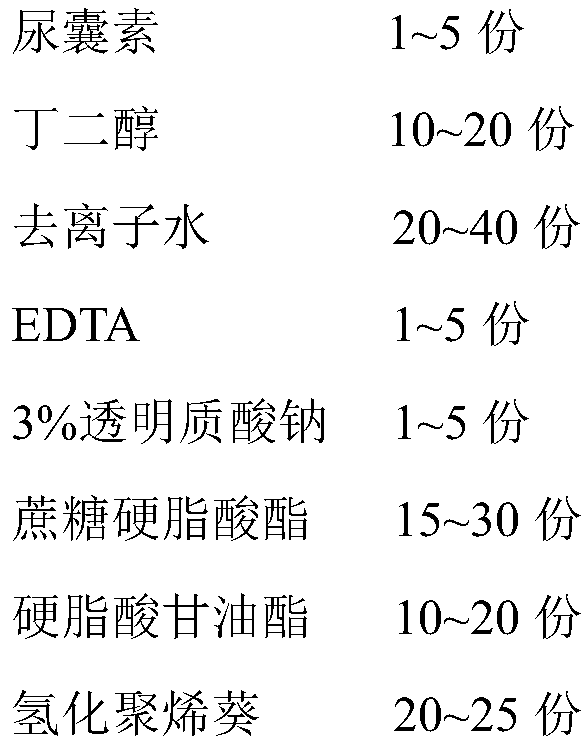

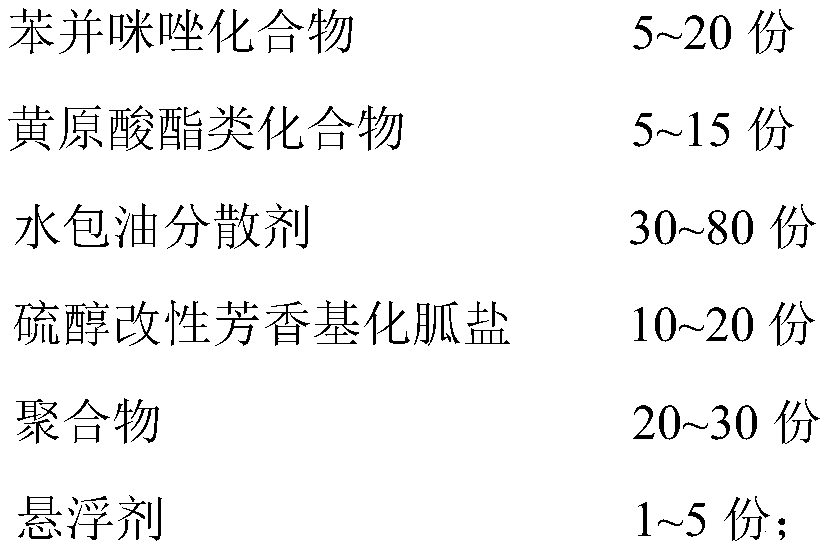

A kind of anti-tarnish protective agent for gold and silver plating and its preparation method and use method

ActiveCN109097759BDoes not affect appearance and conductivityLong vulcanization test timeMetallic material coating processesBenzimidazoleOxidation resistant

The invention relates to a treatment agent for metal after plating, in particular to a gold plating and silver plating anti-discoloration protective agent, and a preparation method and using method thereof. The gold plating and silver plating anti-discoloration protective agent includes a benzimidazole compound, a xanthate compound, an oil-in-water dispersant, mercaptan modified aromatic guanidinesalt, a polymer and a suspension agent. The preparation method of the gold plating and silver plating anti-discoloration protective agent comprises the steps that at the constant temperature of waterbath heating, the benzimidazole compound and the xanthate compound are placed in the oil-in-water dispersant, the polymer and the suspension agent are added, and then the mercaptan modified aromaticguanidine salt is added. The using method of the gold plating and silver plating anti-discoloration protective agent comprises the steps that the anti-discoloration protective agent is dissolved in water, and a plated workpiece is immersed into the water. The anti-discoloration protective agent has the advantages that antioxidant and anti-vulcanization properties are outstanding; technological operation is easy, abrasion resistance is high, and the welding property of the workpiece is not affected; and the workpiece is easy to clean, the anti-discoloration protective agent has no harm to the environment, and the electrical properties of the platings are basically not affected.

Owner:深圳市傲新源科技有限公司

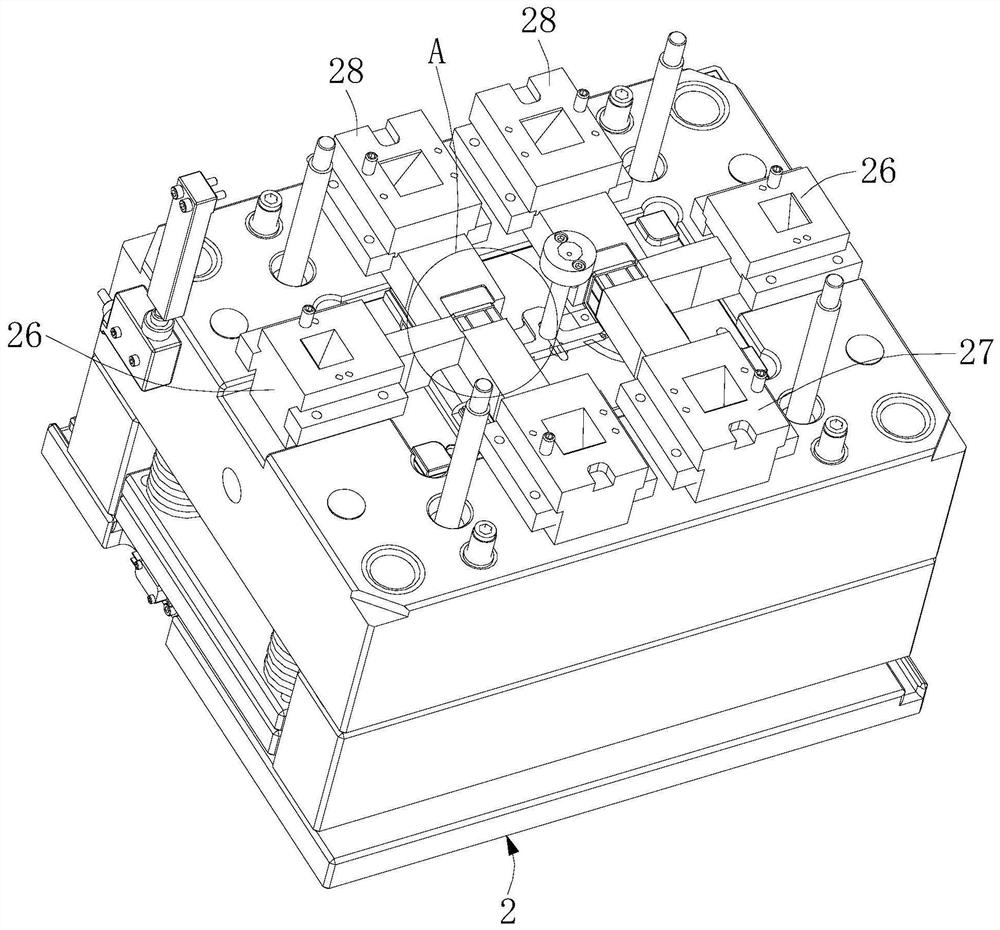

Injection molding method for preventing large-area metal part rubber coating deformation, injection mold and large-area metal part rubber coating product

PendingCN112721025AImprove point pressure resistanceAffect electrical performanceCoatingsInjection mouldingComposite material

The invention belongs to the technical field of injection molds, and particularly discloses an injection molding method for preventing large-area metal part rubber coating deformation, an injection mold and a large-area metal part rubber coating product. The injection molding method comprises the following steps of, 1, determining a stress area of a metal part; 2, putting the metal part into a cavity of the injection mold; 3, carrying out die assembly; 4, controlling supporting columns of the injection mold to move, so that the supporting columns extend into the cavity and abuts against the reverse side of the stress area of the metal part; 5, injecting molten plastic into the cavity; 6, carrying out injection molding pressure maintaining, meanwhile, withdrawing the supporting columns, forming supporting vacant positions by the supporting columns on the metal part, and filling supporting vacant positions with molten plastic under the action of injection molding pressure maintaining; and 7, carrying cooling and mold opening, and taking out a molded rubber-coated product. By supporting the reverse side of the stress area of the metal part in the mold, the defects of injection molding deformation and non-uniform rubber coating thickness of the metal part are prevented.

Owner:瑞晟新能源科技(广东)有限公司

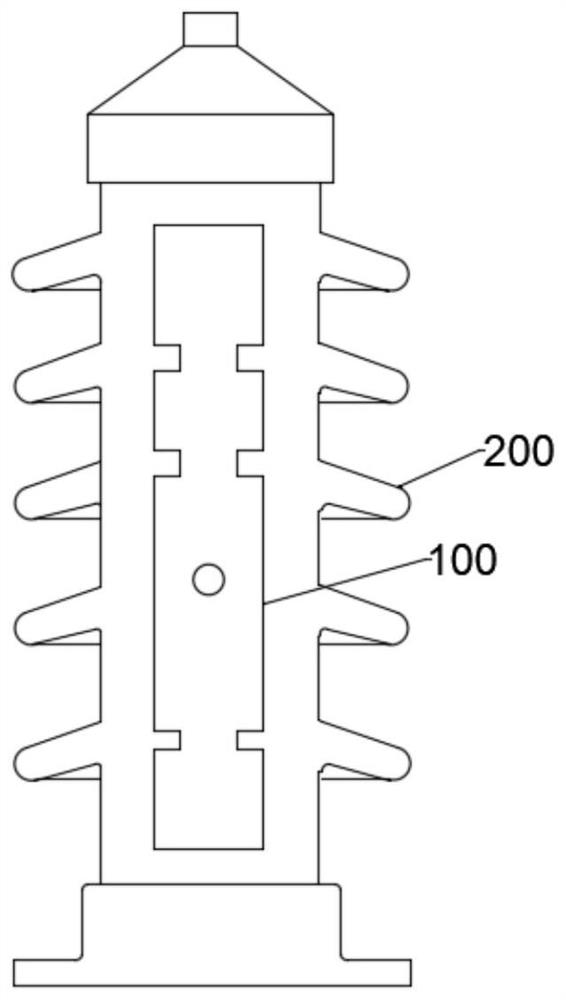

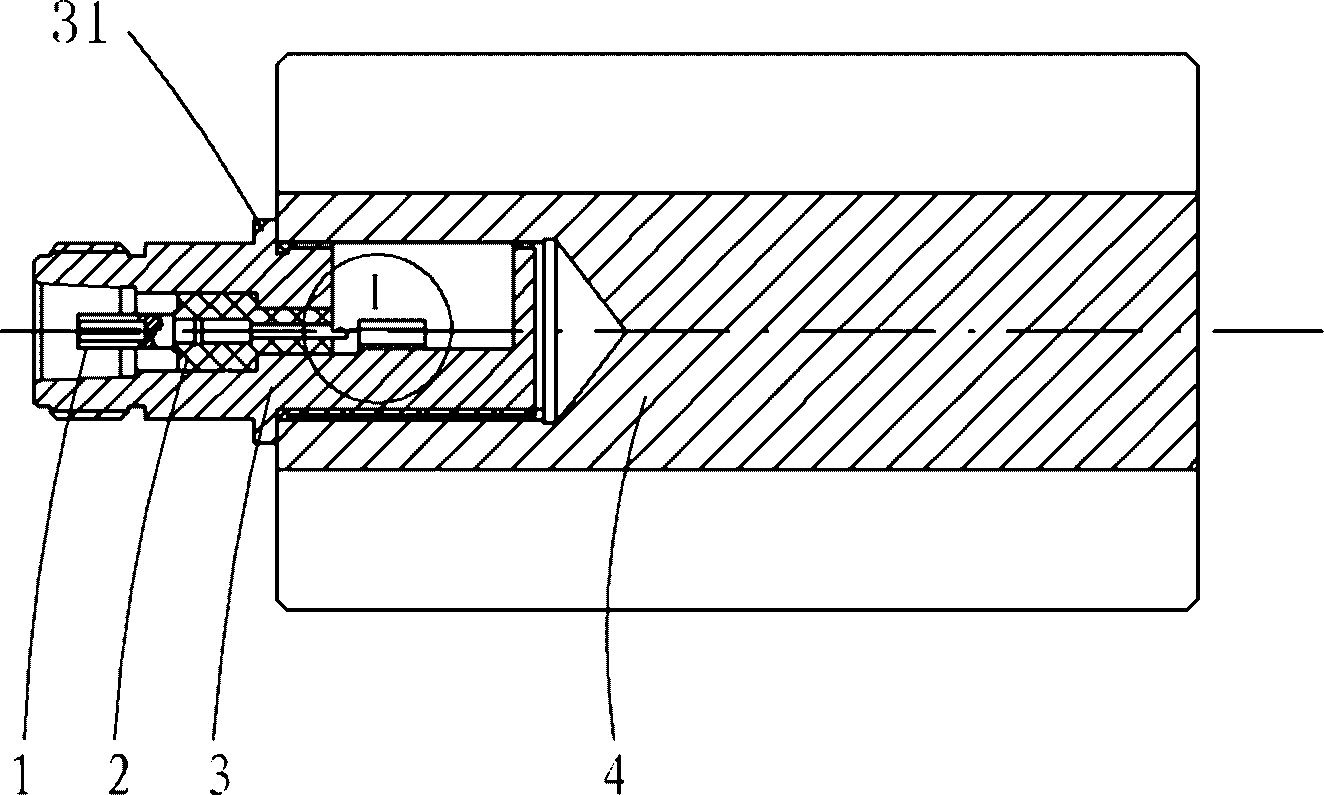

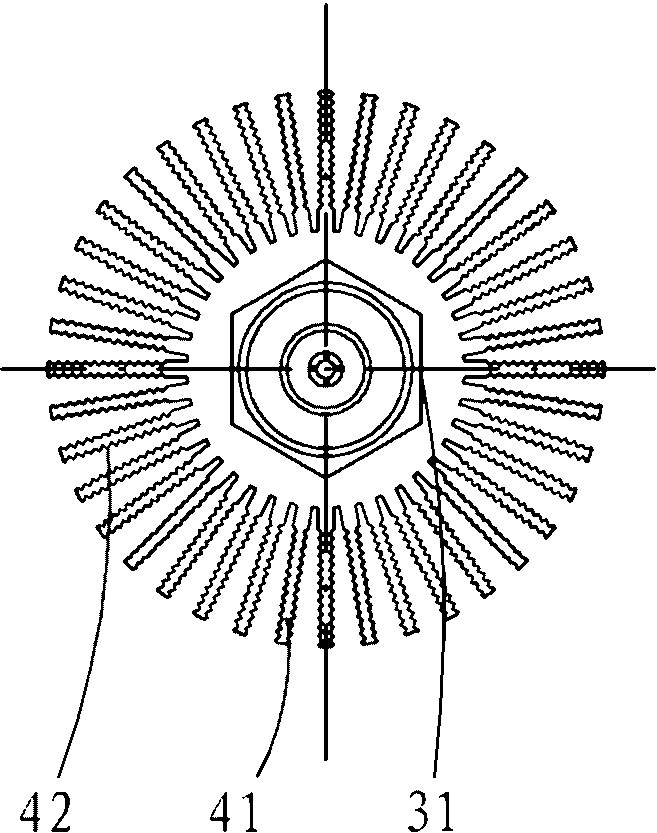

Coaxial load with radial radiating structure

InactiveCN102354785AShorten the processing cycleReduce wasteWaveguide type devicesElectrical conductorHigh volume manufacturing

The invention discloses a coaxial load with a radial radiating structure. The coaxial load comprises a connector and a radial radiator in threaded connection with the connector, wherein the connector is formed by an inner conductor, an insulating medium and an outer conductor which are coaxially arranged from inside to outside; the tail of the outer conductor is in threaded connection with the inner hole of the end face of the radial radiator; an absorbing resistor is fixedly connected in the cavity of the tail of the outer conductor; and the absorbing resistor is fixedly welded together with a welding platform at the tail of the inner conductor. The coaxial load can realize rapid processing, has a concise structure, is simple and reliable in connection, has good price comparability and superior and more stable electrical property and is suitable for mass production.

Owner:合肥佰特微波技术有限公司

Printed circuit board and method for manufacturing printed circuit board

ActiveCN104768326BAffect electrical performanceElectrical connection printed elementsPrinted element electric connection formationMedia layerPrinted circuit board

The invention provides a printed circuit board. The printed circuit board comprises a plurality of sub board bodies. The sub board bodies comprise the first sub board body and the second sub board body. A first medium layer is arranged between the first sub board body and the second sub board body. The first sub board body is located on the outmost side of the printed circuit board. The first surface of the first medium layer is in press fit with the pressing face of the first sub board body, and the second surface is in press fit with the second sub board body. The part, protruding out of the first surface, of a first guide connection column covers hole openings of via holes of the first sub board body. The part, protruding out of the second surface, of the first guide connection column covers hole openings of via holes of the second sub board body so that a conductive metal layer of the via holes of the first sub board body can be electrically connected with a conductive meal layer of the via holes of the second sub board body in a breakover mode through the first guide connection column. The invention provides a printed circuit board manufacturing method.

Owner:HONOR DEVICE CO LTD

Plastic-encapsulated branch device and assembling process thereof

PendingCN110635282ATo achieve connection conductionEasy constructionContact member assembly/disassemblySecuring/insulating coupling contact membersFirst FillCable gland

The invention discloses a plastic-encapsulated branch device which comprises a locking nut. A shuttle-shaped spring chuck is arranged in the locking nut. The spring chuck and the locking nut are locked through a tapered sleeve. The tapered sleeve is connected with a branch cable through a straight terminal. A first filling plastic layer wraps outside the locking nut. The first filling plastic layer is internally provided with a Z-shaped terminal. One end of the Z-shaped terminal is coaxial with the locking nut, and the other end is connected with the branch cable. The first filling plastic layer is wrapped by a second filling plastic layer. One end of the first filling plastic layer and one end of the second filling plastic layer are fixedly connected with a flange plate and a cable gland.The assembling process comprises steps S1-S9. The device is fixed on the customer's mechanism through the flange plate between the client sides so that the construction is convenient and use is convenient for the customer; the forming process completely fills the gaps of the parts, and the electrical performance is better under the same volume; and the clamping process is adopted to realize the power extraction of the shielding layer, and the production process is simple and reliable.

Owner:成都合众宝根电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com