Injection molding method for preventing large-area metal part rubber coating deformation, injection mold and large-area metal part rubber coating product

A large-area metal and injection mold technology, applied in the direction of coating, etc., can solve the problems of electrical insulation, voltage resistance and electrical performance that cannot meet customer standards, uneven product thickness, and affect the assembly of finished products, so as to prevent rubber coating Effects of uneven meat thickness, reduction of deformation, and improvement of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

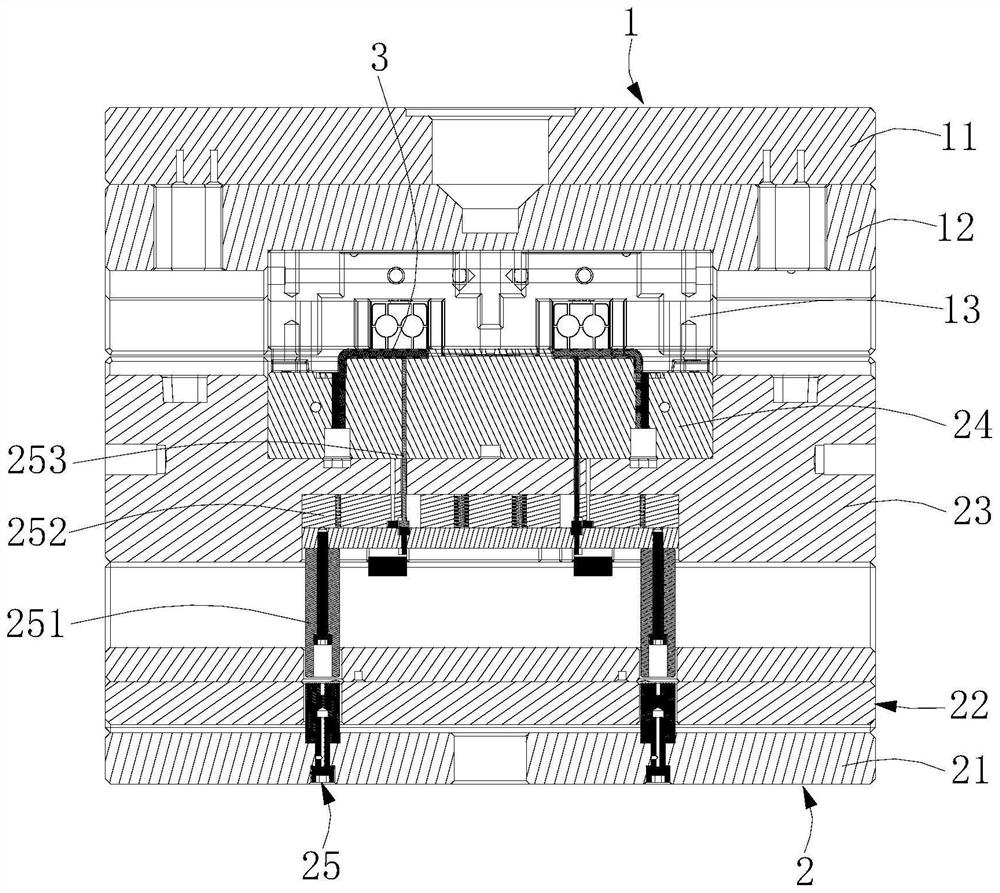

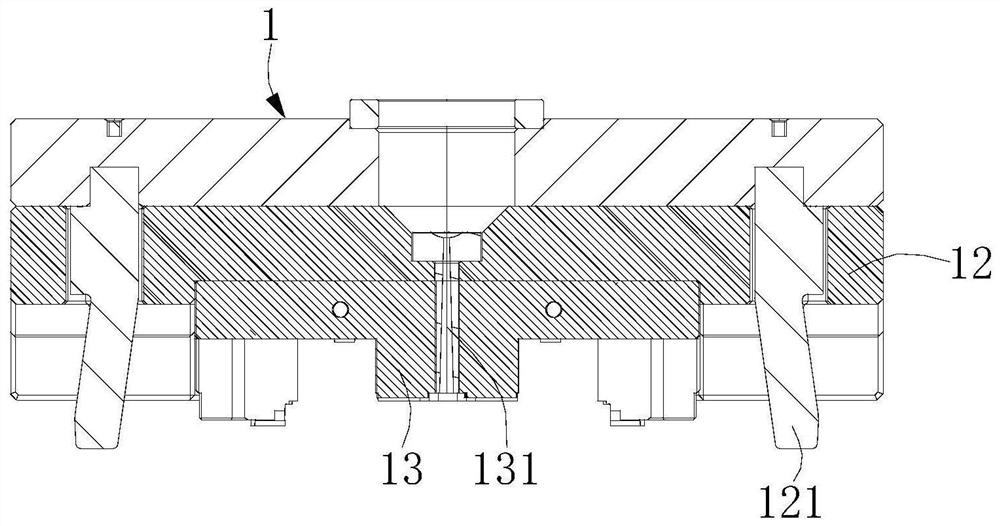

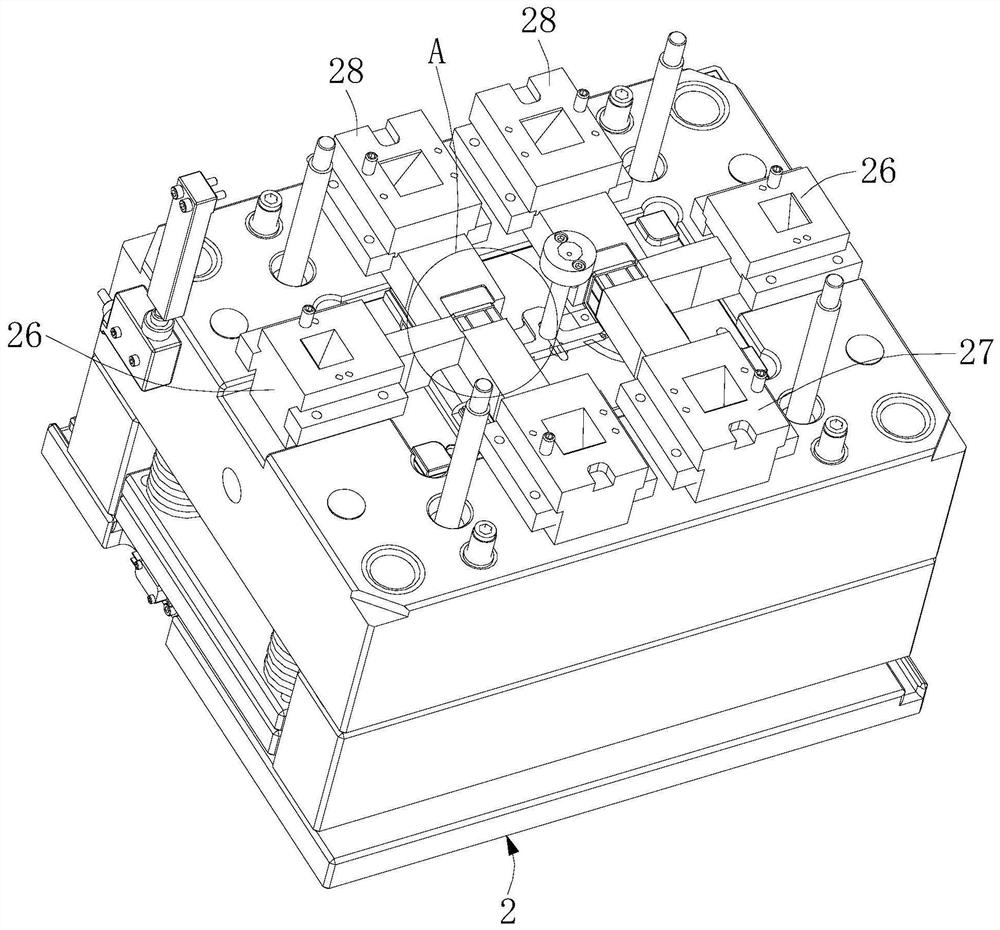

[0052] refer to Figure 1 to Figure 8 , an injection molding method for preventing deformation of large-area metal parts, comprising the following steps:

[0053] Step 1. Determine the stressed area 411 of the metal part 41 through mold flow analysis;

[0054] Step 11, open a plurality of glue passing holes 412 and a plurality of positioning holes 413 at intervals in the stressed area 411 of the metal part 41, so that the plurality of glue passing holes 412 are located at the edge of the metal part 41, and the plurality of positioning holes 413 and the injection mold A plurality of supporting pillars 253 in one-to-one correspondence;

[0055] Step 2. Put the metal part 41 into a fixed position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com