Welding system and welding method for metal parts and coaxial cables

A coaxial cable and welding system technology, applied in welding equipment, metal processing equipment, connection, etc., can solve problems such as inability to effectively ensure electrical connection continuity, high pollution of waste water and waste gas, and low processing efficiency, so as to reduce labor costs Labor, automatic processing, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] welding system

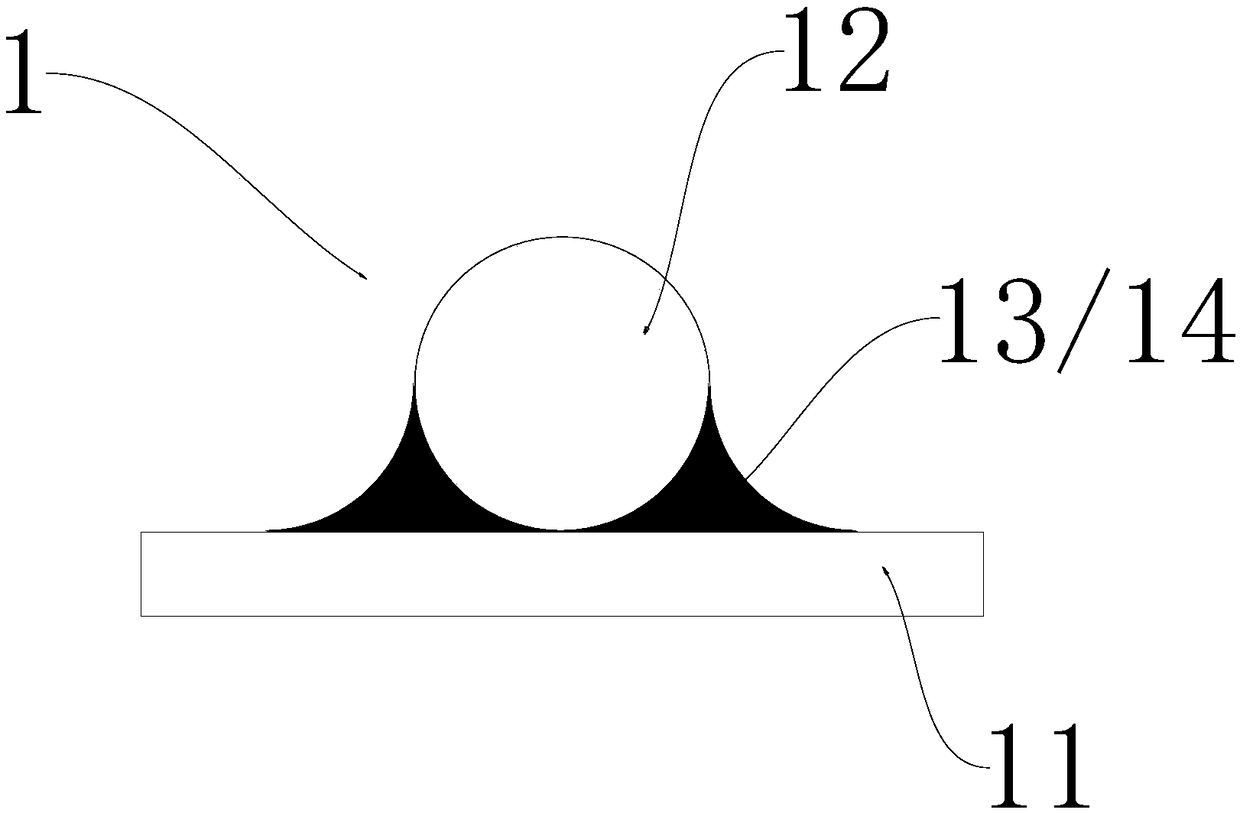

[0053] refer to figure 1 , shows a welded structure 1 to be obtained by welding a metal part and a coaxial cable. The welded structure 1 includes a metal part 11 providing a welding base, a coaxial cable 12 and solder 13 filled in a weld 14 . figure 1 In the illustrated embodiment, the metal piece 11 provides a plane as a soldering surface, and the solder 13 extends from the lower half of the coaxial cable 12 to the surface of the metal piece 11 due to gravity in a molten state. , and diffuse from directly below the coaxial cable 12 to both sides until the molten solder 13 no longer diffuses based on its own material properties and cooling effect, and finally the solder 13 is between the metal piece 11 and the coaxial cable 12 solidification to form solder joints.

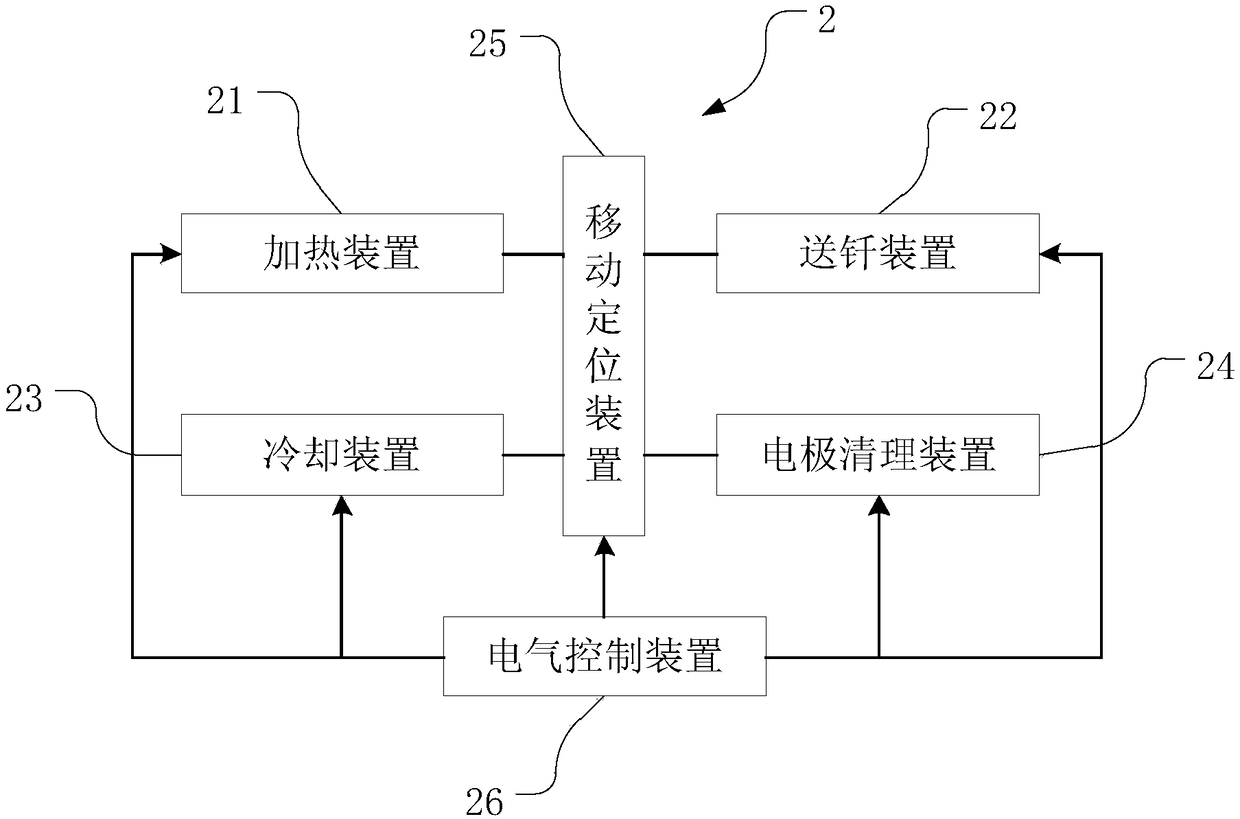

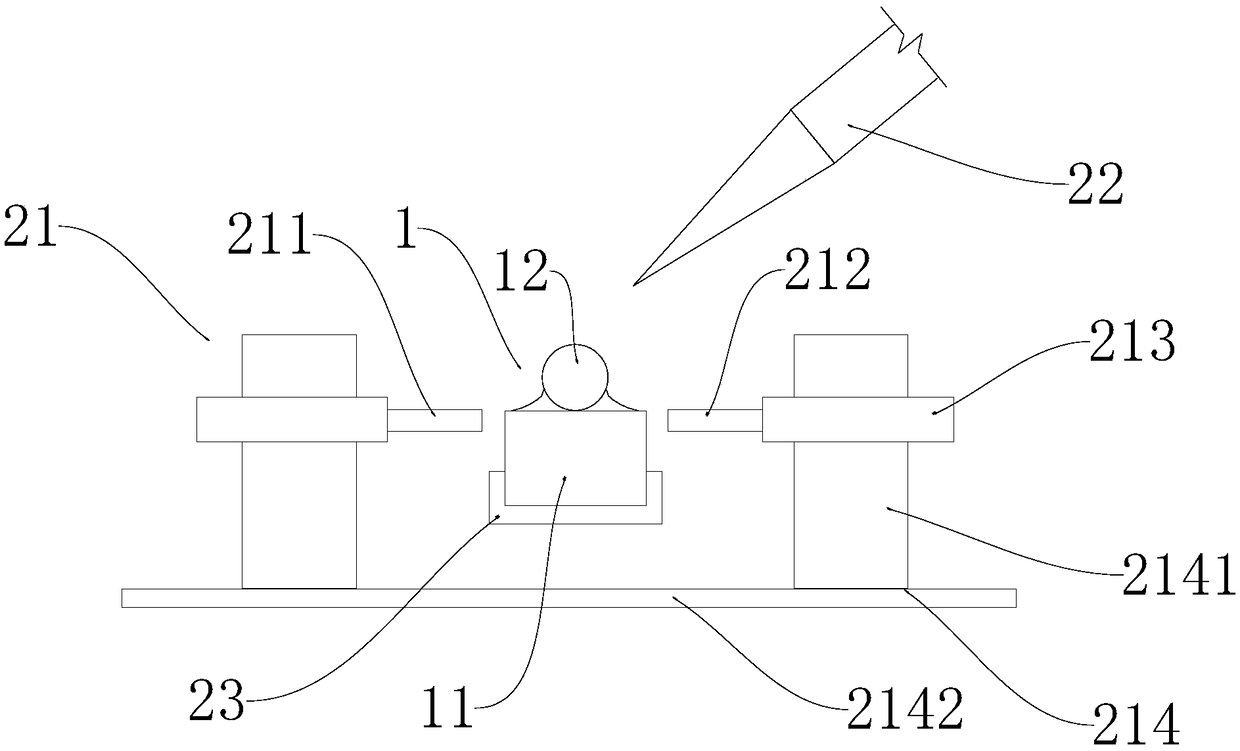

[0054] refer to figure 2, which shows a welding system 2 of metal parts and coaxial cables, the welding system 2 is used to form the welding structure 1 . Specifically, the welding syst...

Embodiment 2

[0065] Welding method

[0066] refer to Figure 5 , the present invention also provides a welding method of a metal part and a coaxial cable, which comprises the following steps:

[0067] S1: Prepare the metal parts and coaxial cables and transfer them to the processing station;

[0068] Specifically, the metal part and the coaxial cable are moved to the processing station by the moving positioning device 25 . Firstly, by manual operation, the metal part 11 and the coaxial cable 12 are fixed on the workpiece fixture to maintain the preset positional relationship, so as to facilitate subsequent welding to form the welding structure 1; then, the clamping A workpiece fixture with a metal piece 11 and a coaxial cable 12 is fixed on the delivery mechanism, and the workpiece fixture is moved to the processing station by manual push or motor drive.

[0069] Those skilled in the art should understand that in the case of mature automated production, the above-mentioned procedures th...

Embodiment 3

[0083] The condition of the welding surface of the metal parts

[0084] refer to figure 1 , Figure 6 and Figure 7 , the welding structure 1 is roughly divided into three implementations based on the welding surface provided by the metal piece 11:

[0085] Such as figure 1 The illustrated implementation manner has been described in detail in the foregoing embodiment 1 and will not be repeated.

[0086] Such as Figure 6 and Figure 7As shown, in order to facilitate the positioning between the metal part 11 and the coaxial cable 12, the welding surface located on the surface of the metal part 11 will be set in the groove 111 that can accommodate the coaxial cable 12, the groove After accommodating the coaxial cable 12 in 111 , there is a gap between the bottom of the groove 111 and the coaxial cable 12 .

[0087] When the bottom of the groove 111 is a curved surface, the welding surface has a curved surface, and the gap also has a curved surface. The brazing material 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com