A kind of anti-tarnish protective agent for gold and silver plating and its preparation method and use method

An anti-discoloration and protective agent technology, applied in the direction of metal material coating process, etc., can solve the problem of gold and silver plating layer refusal to solder, etc., to prevent discoloration, oxidation resistance and vulcanization performance, without affecting appearance and conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

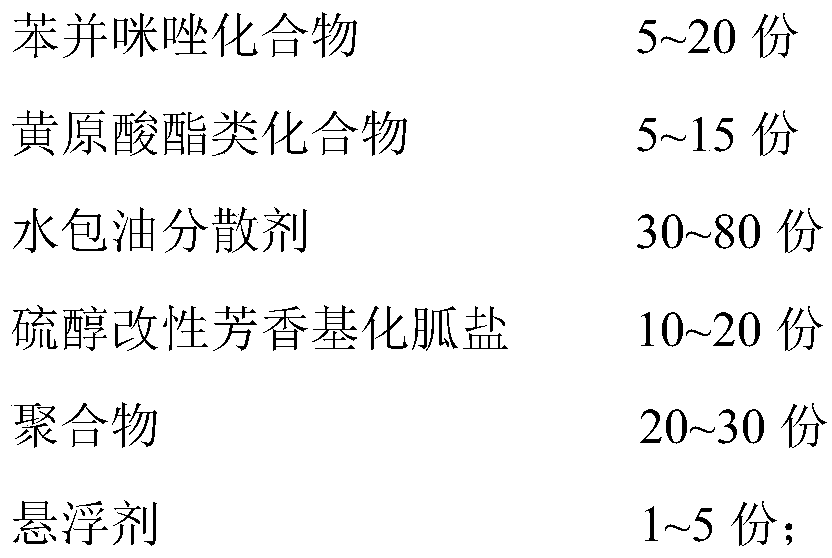

[0041] Specific embodiment 1 (1kg is example)

[0042] 2-Phenylthiobenzimidazole 100g

[0043] Ethyl xanthate formate 50g

[0044] Oil-in-water dispersant 480g

[0045] Chiral mercaptan modified arylated guanidine salt 110g

[0046] Polyvinyl alcohol 250g

[0047] o-toluic acid 6g;

[0048] Phosphorus oxychloride 4g

[0049] Preparation method:

[0050] (1) Add 100g of 2-phenylthiobenzimidazole and 50g of ethyl xanthate ethyl formate into the oil-in-water dispersant and keep stirring for 30min in a constant temperature water bath at 55°C;

[0051] (2) Keeping the temperature constant, in the state of continuous stirring, slowly add 4g phosphorus oxychloride and 6g o-tolylacetic acid dropwise after adding 250g polyvinyl alcohol in (1), and stir for 5min;

[0052](3) Keeping the temperature constant, add 110 g of chiral mercaptan-modified arylated guanidine salt to (2) under continuous stirring, continue stirring for 1 hour, mix well, keep warm at 55° C. for 3 hours, and ...

specific Embodiment 2

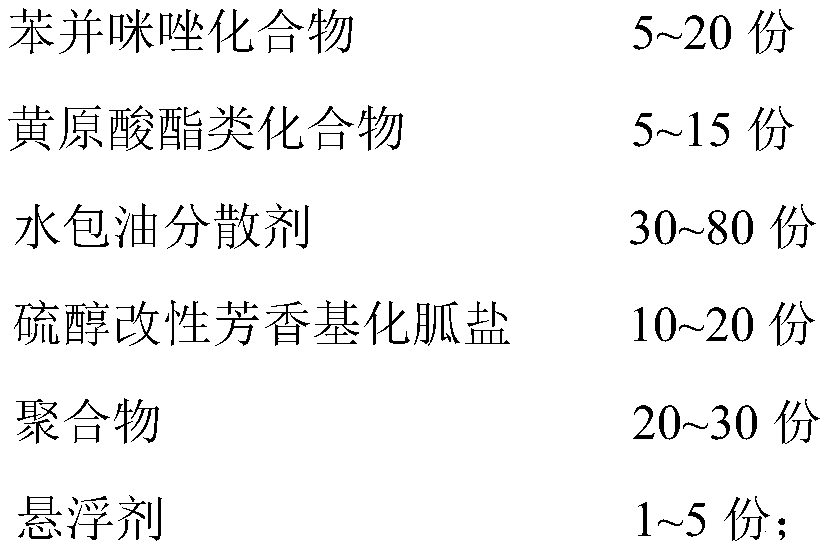

[0058] Specific embodiment 2 (1kg is example)

[0059]

[0060] Chiral mercaptan modified arylated guanidine salt 100g

[0061] Polystyrene 80g

[0062] Polyethylene glycol 150g

[0063] 13g o-methylphenylacetic acid;

[0064] Phosphorus oxychloride 7g

[0065] Preparation method:

[0066] (1) Add 50g of 2-phenyl-5-benzimidazole sulfonic acid and 150g of ethyl cellulose xanthate formate to 480g of oil-in-water dispersant and continue stirring for 30min in a constant temperature water bath at 58°C;

[0067] (2) Keeping the temperature constant, under continuous stirring, add 80g polystyrene and 150g polyethylene glycol to (1) and slowly add 7g phosphorus oxychloride and 13g o-tolylacetic acid dropwise, and stir for 5min ;

[0068] (3) Keeping the temperature constant, add chiral thiol-modified arylated guanidine salt to (2) under continuous stirring, continue stirring for 1 hour, mix well, keep warm at 58° C. for 2.5 hours, and then pack and use.

[0069] Instructions...

specific Embodiment 3

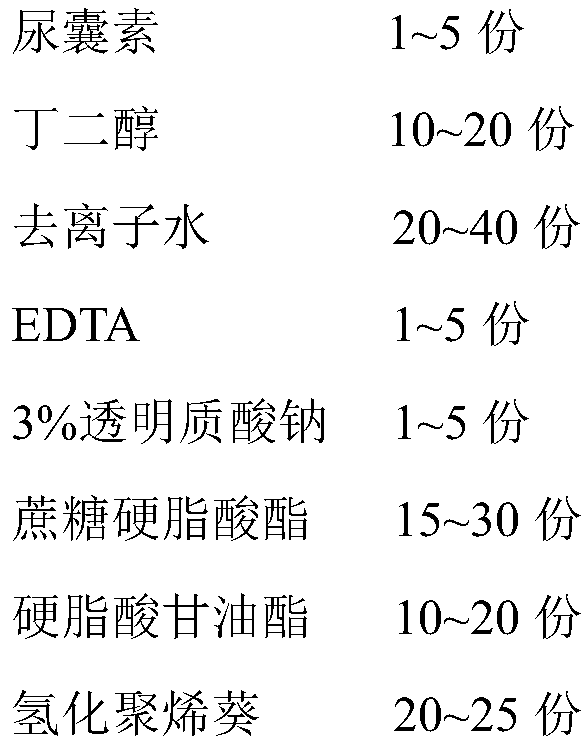

[0074] Specific embodiment 3 (1kg is example)

[0075]

[0076]

[0077] Preparation method:

[0078] (1) Add 80g of 2-(2-aminophenyl)-1H-benzimidazole and 100g of ethyl isobutylxanthate formate to 550g of oil-in-water dispersant and keep stirring for 30min in a constant temperature water bath at 60°C;

[0079] (2) Keeping the temperature constant, in the state of continuous stirring, slowly add 3g of phosphorus oxychloride and 2g of 3-mercaptobenzoic acid dropwise after adding 100g of polyvinyl chloride in (1), and stir for 5min;

[0080] (3) Keeping the temperature constant, add 165g of chiral thiol-modified arylated guanidine salt to (2) under continuous stirring, continue stirring for 1 hour, mix well, keep warm at 60°C for 3 hours, and then pack it for use.

[0081] Instructions:

[0082] (1) Put 500 g of deionized water in a beaker, add 50 g of the protective agent composition of Example 3, stir to dissolve it completely, and add deionized water to make the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com