Coaxial load with radial radiating structure

A technology of heat dissipation structure and coaxial load, applied in electrical components, circuits, waveguide devices, etc., can solve the problems of high product cost, increased cumulative error of product mechanical parameters, small competitive advantage, etc., to achieve product consistency guarantee , The effect of reducing raw material waste and shortening processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

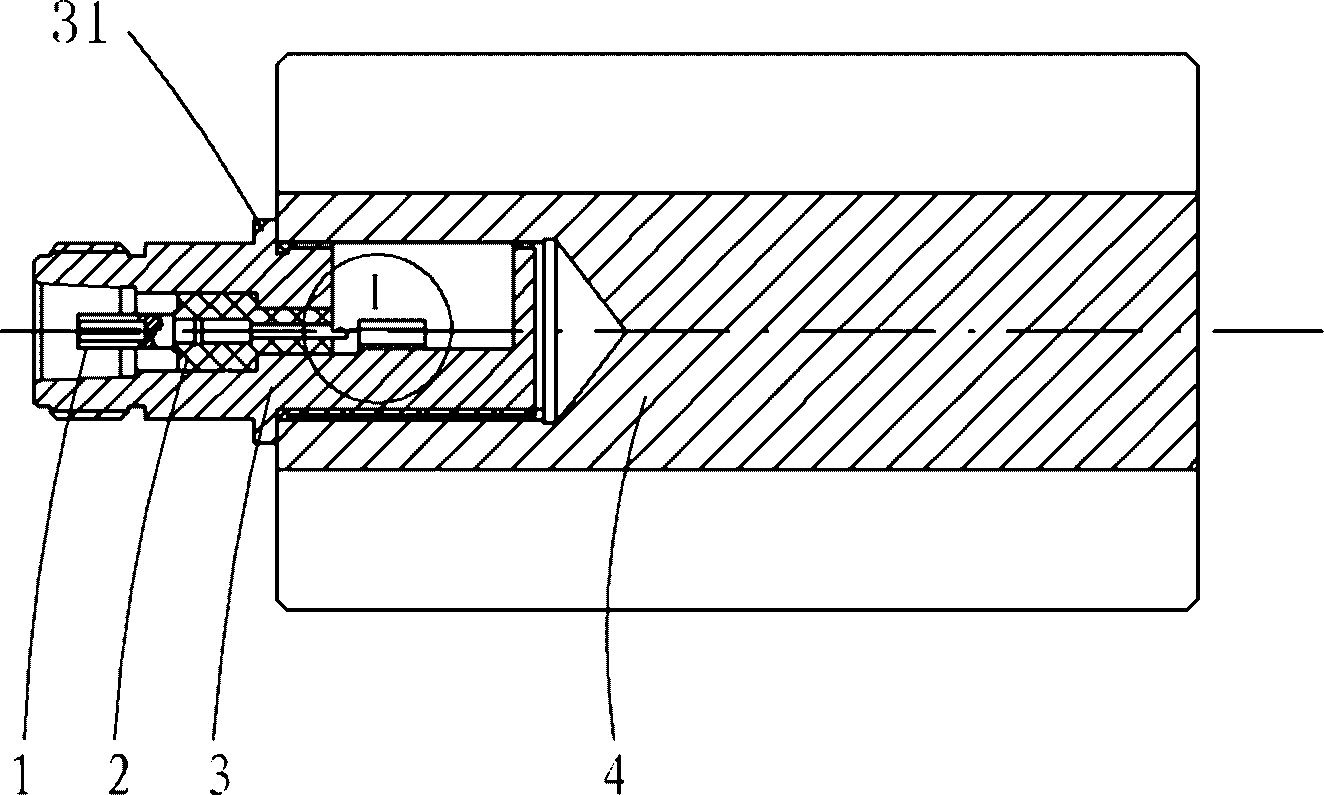

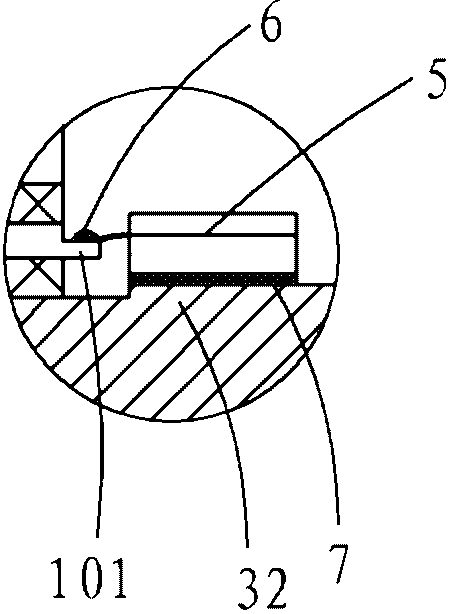

[0017] Example: see Figure 1A-Figure 1C , the coaxial load of this embodiment, its heat dissipation part is a radiator with a radial heat dissipation structure, the coaxial load of this embodiment includes a connector and a radial radiator 4 threaded with the connector, and the connector is from the inside to the The outer part is composed of an inner conductor 1, an insulating medium 2 and an outer conductor 3 arranged coaxially. The tail of the outer conductor 3 is screwed into the inner hole of the end face of the radial radiator 4, and an absorber is fixedly connected in the inner cavity of the tail of the outer conductor 3. The resistance 5 and the absorption resistance 5 are welded and fixed to the welding platform 101 provided at the end of the inner conductor 1 .

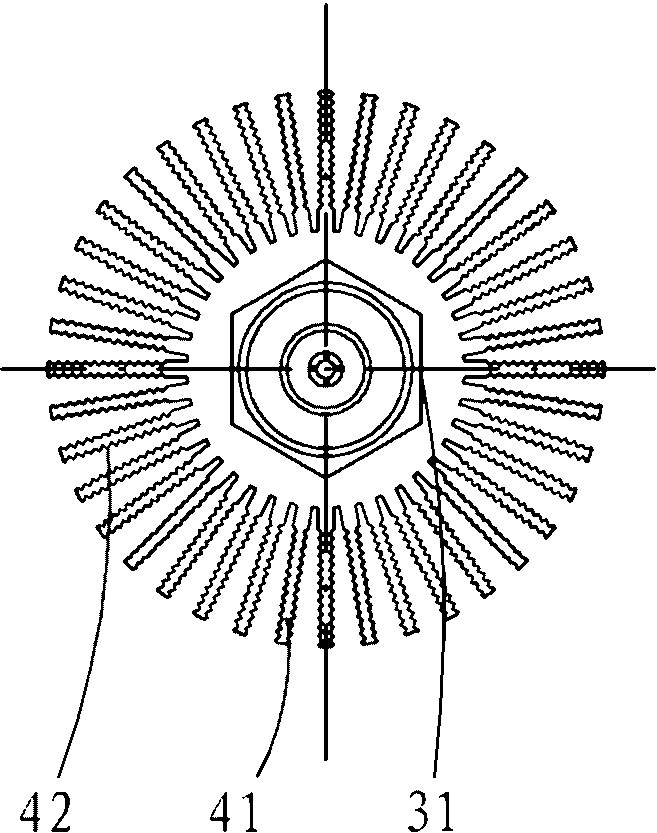

[0018] In specific settings, Figure 1B As shown, the radial radiator 4 has a cylindrical shape as a whole, and a plurality of cooling fins 41 are arranged on the outer circumference of the radiator, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com