A composite insulator with alumina porcelain core rod and its manufacturing method

A composite insulator and a manufacturing method of technology, which are applied to insulators, clay products, other household appliances, etc., can solve the problems that affect the normal use and promotion of insulators, reduce the bonding force of silicone rubber sheds, and increase the cost of resin cores, and improve the bending strength. , The effect of improving the interface stress and improving the bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

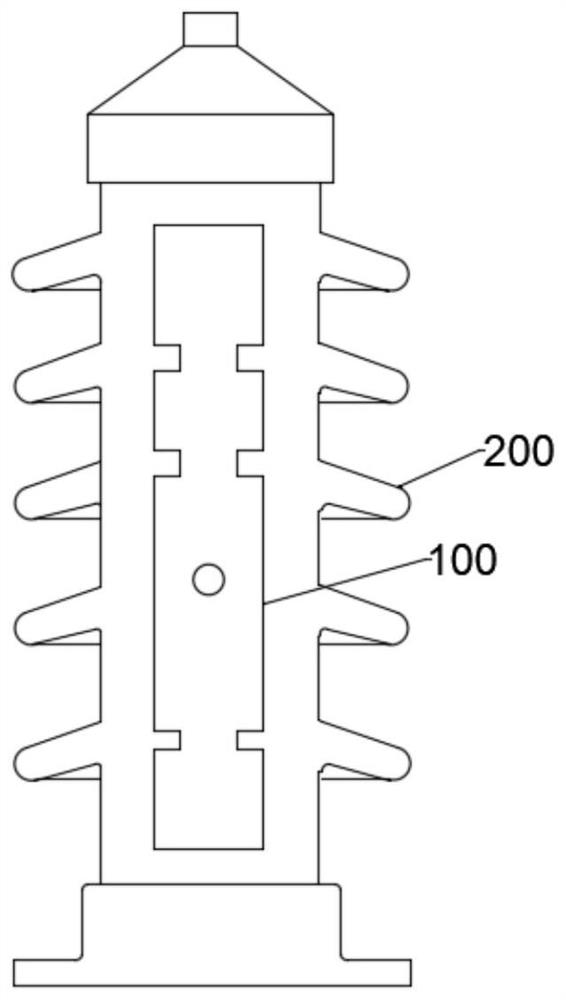

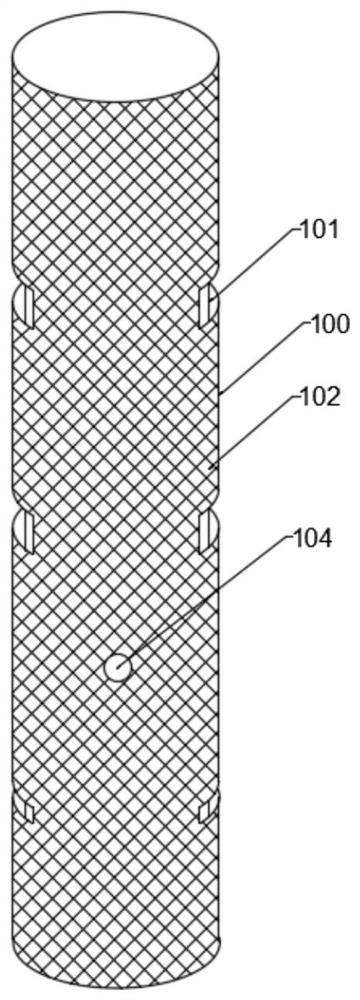

[0037] Such as Figure 1-3 As shown, an alumina ceramic core rod composite insulator includes an alumina ceramic core rod 100 and an shed jacket 200 covering the outside of the alumina ceramic core rod 100. The alumina ceramic core rod 100 is cylindrical, and the At least one groove 101 is provided on the side of the alumina ceramic mandrel 100;

[0038] The outer wall of the alumina ceramic core rod 100 is provided with a reinforcing part.

[0039] In a specific implementation, the reinforcing part includes grooves or protrusions, and the grooves or protrusions enclose a grid-like region 102 on the outer surface of the alumina ceramic core rod.

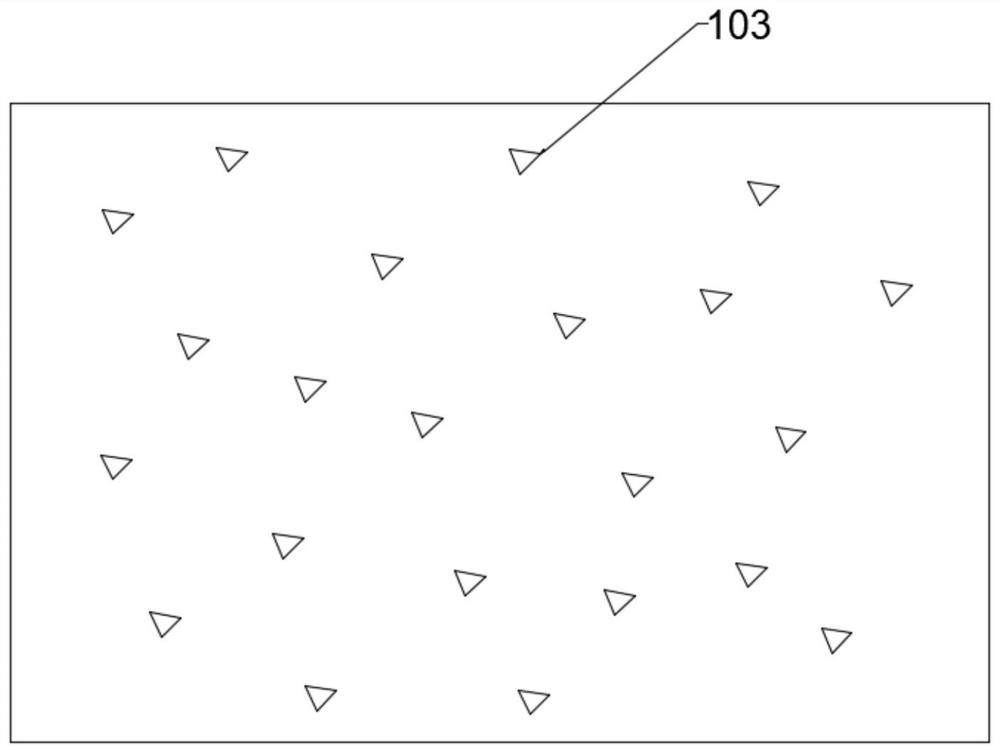

[0040] Specifically, a number of triangular positioning blocks 103 arranged in disorder are arranged on the grid-shaped area 102 .

[0041] Specifically, one of the included angles of the triangular positioning blocks 103 is 30-40°, and each side of adjacent triangular positioning blocks 103 is not on the same straight line.

[00...

Embodiment 2

[0045] A method for manufacturing an alumina porcelain core rod composite insulator, comprising the following steps:

[0046]S1: Mix 10 parts by weight of industrial alumina powder, 5 parts of calcined bauxite powder, 20 parts of feldspar, 25 parts of clay, and 20 parts of calcined kaolin, and wet grind until the particle size of the powder is less than 5 μm Slurry, press the qualified mud to vacuum mud;

[0047] S2: Using the mold forming method to prepare the alumina ceramic mandrel green body; in the specific implementation, the mold adopts a mold with a grid shape and a triangular positioning block;

[0048] S3: Spraying or dipping glaze on the green body of alumina ceramic mandrel and firing it once to obtain a semi-finished porcelain mandrel; the glaze contains the following raw materials in parts by weight: 3 parts of silica sol, 1 part of methyl silane, 15 parts of acetic acid parts, 75 parts of propanol, and 10 parts of prefabricated glass flakes; the processing proc...

Embodiment 3

[0052] A method for manufacturing an alumina porcelain core rod composite insulator, comprising the following steps:

[0053] S1: Mix 20 parts by weight of industrial alumina powder, 10 parts of calcined bauxite powder, 20 parts of feldspar, 35 parts of clay, and 20 parts of calcined kaolin, and wet grind until the particle size of the powder is less than 5 μm Slurry, press the qualified mud to vacuum mud;

[0054] S2: Using a mold forming method to prepare a green body of alumina ceramic core rod;

[0055] S3: Spraying or glazing the green body of the alumina ceramic mandrel and firing it once to obtain a semi-finished porcelain mandrel; the glaze contains the following raw materials in parts by weight: 3 parts of silica sol, 2 parts of methyl silane, and 20 parts of acetic acid parts, 80 parts of propanol, and 20 parts of prefabricated glass flakes; the treatment process of the prefabricated glass flakes is to immerse the glass flakes in a coupling agent solution for 4 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com