High-temperature-resistant hot-melt self-adhesive enameled wire

A self-adhesive paint and warm technology, applied in the field of enameled wire, can solve the problems of high manufacturing difficulty, increased diameter and high production cost, improve insulation performance and heat resistance, prevent excessive traction or pressure, and improve electrical performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

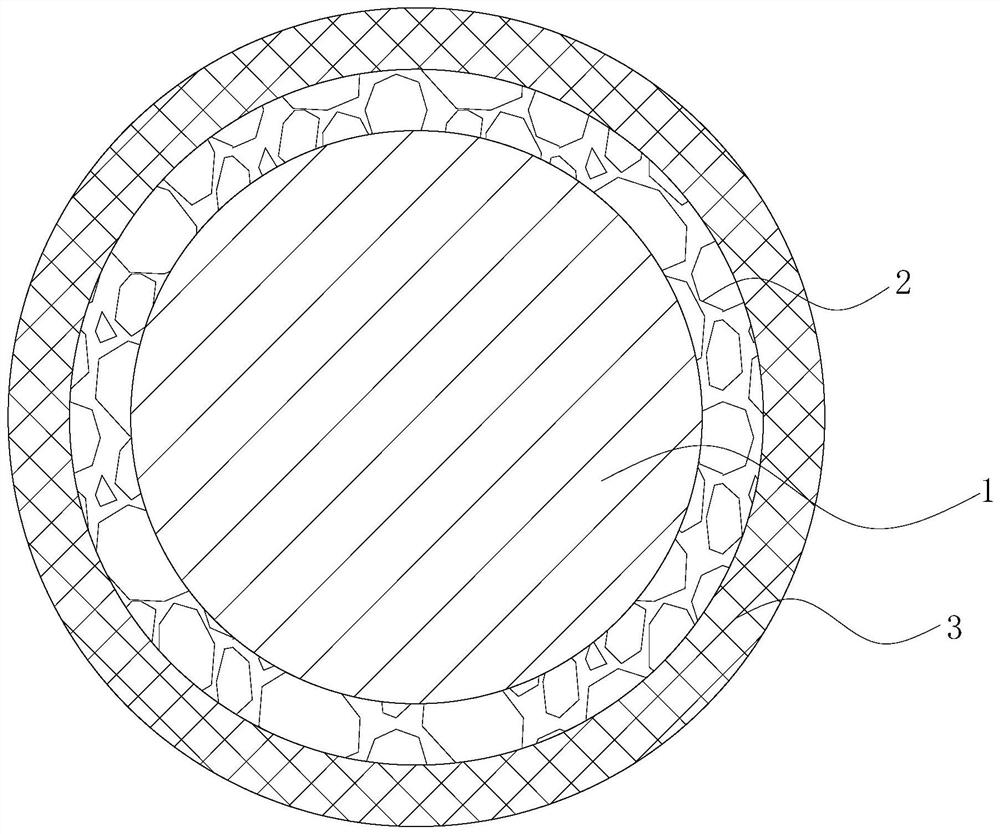

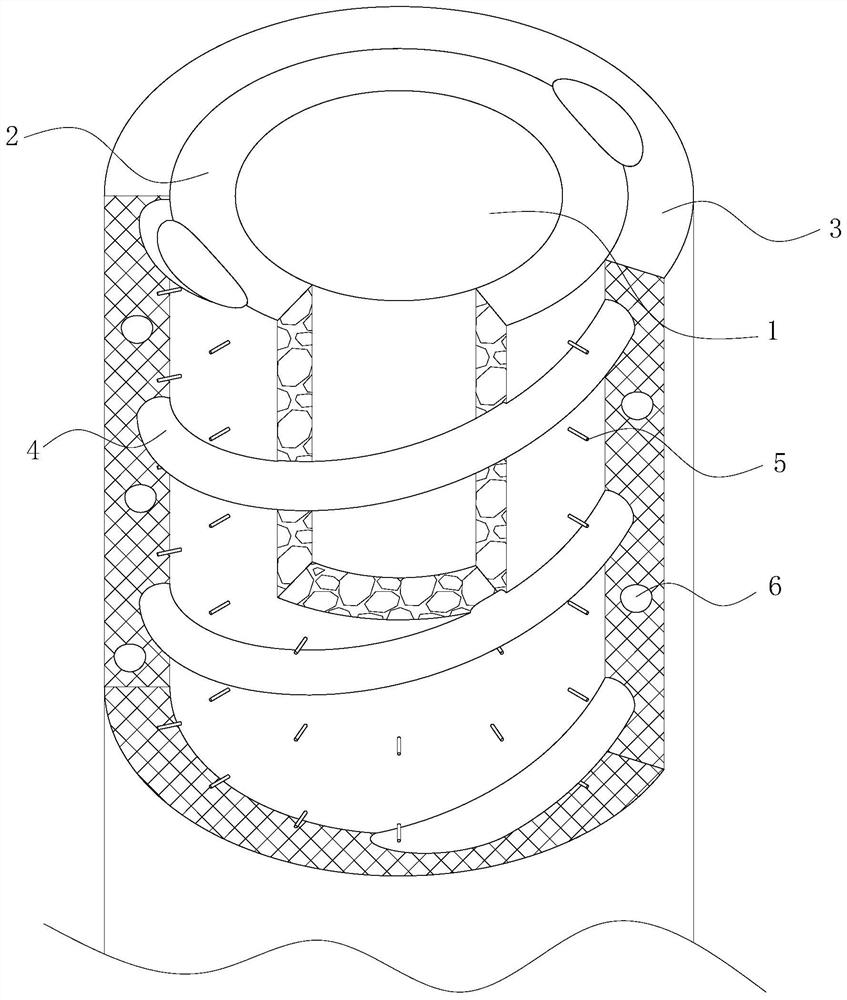

[0029] As an embodiment of the present invention, solidified particles 6 are evenly mixed in the hot-melt self-adhesive paint in the surface layer 3; the solidified particles 6 are mixed into the hot-melt self-adhesive paint by mechanical stirring; the solidified The particle size of the particle 6 is 300-400 mesh; the cured particle 6 added in the surface layer 3 is 15-18wt%; the cured particle 6 is made of a thermosetting resin; the thermosetting resin undergoes a crosslinking reaction and begins to cure , the temperature of the hot-melt self-adhesive paint in the surface layer 3 is higher than its melting point;

[0030] When working, during use, after the coil prepared by the enameled wire is heated, the surface layer 3 of the enameled wire in the coil melts, thereby bonding and fixing each other. At the same time, during the coil heating process, the surface layer 3 in the coil The mixed cured particles 6 are heated, cross-linking reaction occurs, and a network structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com