Single-liquid type low-temperature cured special glue for temperature fuse and preparation method thereof

A thermal fuse, low temperature technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of affecting the electrical performance of fuses, deterioration of fuse performance, low bonding strength of glue, etc., to achieve good bonding performance, The effect of low curing temperature and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

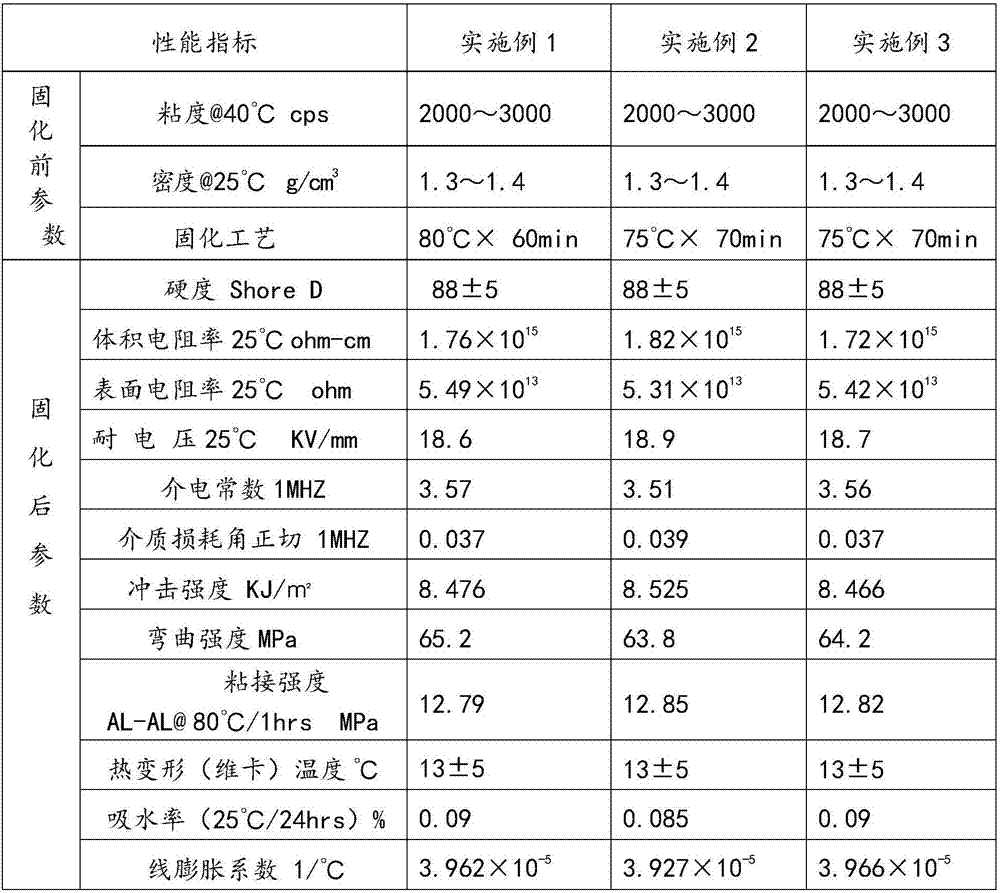

Embodiment 1

[0029] A single-component low-temperature curing thermal fuse special adhesive, which is made of the following components in parts by weight: 45 parts of bisphenol A epoxy resin, 8 parts of flexible epoxy resin, 8 parts of rutile titanium dioxide, 0.7 parts of defoaming and leveling agent, 15 parts of diaminoimidazole triazine complex and 25 parts of phenoxy polyphosphazene.

[0030] The bisphenol A type epoxy resin is rectified bisphenol A type epoxy resin, its viscosity at 40°C is 1000-1500cps, the epoxy equivalent is 184-190, and the total chlorine content is lower than 1200ppm, specifically Shell 828E resin.

[0031] The flexible epoxy resin is a flexible long-chain epoxy resin with a viscosity of 100-150 cps at 40° C., an epoxy equivalent of 120-140, and zero halogen content. Specifically, Taiwan Nanya 331L modified resin can be selected.

[0032] The VOC content of the defoaming and leveling agent is less than 2wt%.

Embodiment 2

[0044] A single-component low-temperature curing special adhesive for thermal fuses, which is made of the following components in parts by weight: 40 parts of bisphenol A epoxy resin, 10 parts of flexible epoxy resin, 5 parts of nano-scale carbon black, 0.5 parts of defoaming and leveling agent, 25 parts of diaminoimidazole triazine complex and 20 parts of phenoxy polyphosphazene.

[0045] The bisphenol A type epoxy resin is rectified bisphenol A type epoxy resin, its viscosity at 40°C is 1000-1500cps, the epoxy equivalent is 184-190, and the total chlorine content is lower than 1200ppm, specifically Shell 828E resin.

[0046] The flexible epoxy resin is a flexible long-chain epoxy resin with a viscosity of 100-150 cps at 40° C., an epoxy equivalent of 120-140, and zero halogen content. Specifically, Taiwan Nanya 331L modified resin can be selected.

[0047] The VOC content of the defoaming and leveling agent is less than 2wt%.

[0048] The particle size of the nano-scale ca...

Embodiment 3

[0059] A single-component low-temperature-cured thermal fuse special adhesive, which is made of the following components in parts by weight: 50 parts of bisphenol A epoxy resin, 5 parts of flexible epoxy resin, 3 parts of rutile titanium dioxide, 2 parts of defoaming and leveling agent, 20 parts of diaminoimidazole triazine complex and 30 parts of aluminum hydroxide.

[0060] The bisphenol A type epoxy resin is rectified bisphenol A type epoxy resin, its viscosity at 40°C is 1000-1500cps, the epoxy equivalent is 184-190, and the total chlorine content is lower than 1200ppm, specifically Shell 828E resin.

[0061] The flexible epoxy resin is a flexible long-chain epoxy resin with a viscosity of 100-150 cps at 40° C., an epoxy equivalent of 120-140, and zero halogen content. Specifically, Taiwan Nanya 331L modified resin can be selected.

[0062] The VOC content of the defoaming and leveling agent is less than 2wt%.

[0063] The particle size of the rutile titanium dioxide is 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com