an electrical connector

A technology for electrical connectors and connecting parts, which is applied in the direction of connection, parts and circuits of connecting devices, etc., can solve the problems of terminal elastic collapse, high cost of electrical connectors, and affecting the electrical performance of electrical connectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A detailed description will be given below in conjunction with the accompanying drawings and embodiments.

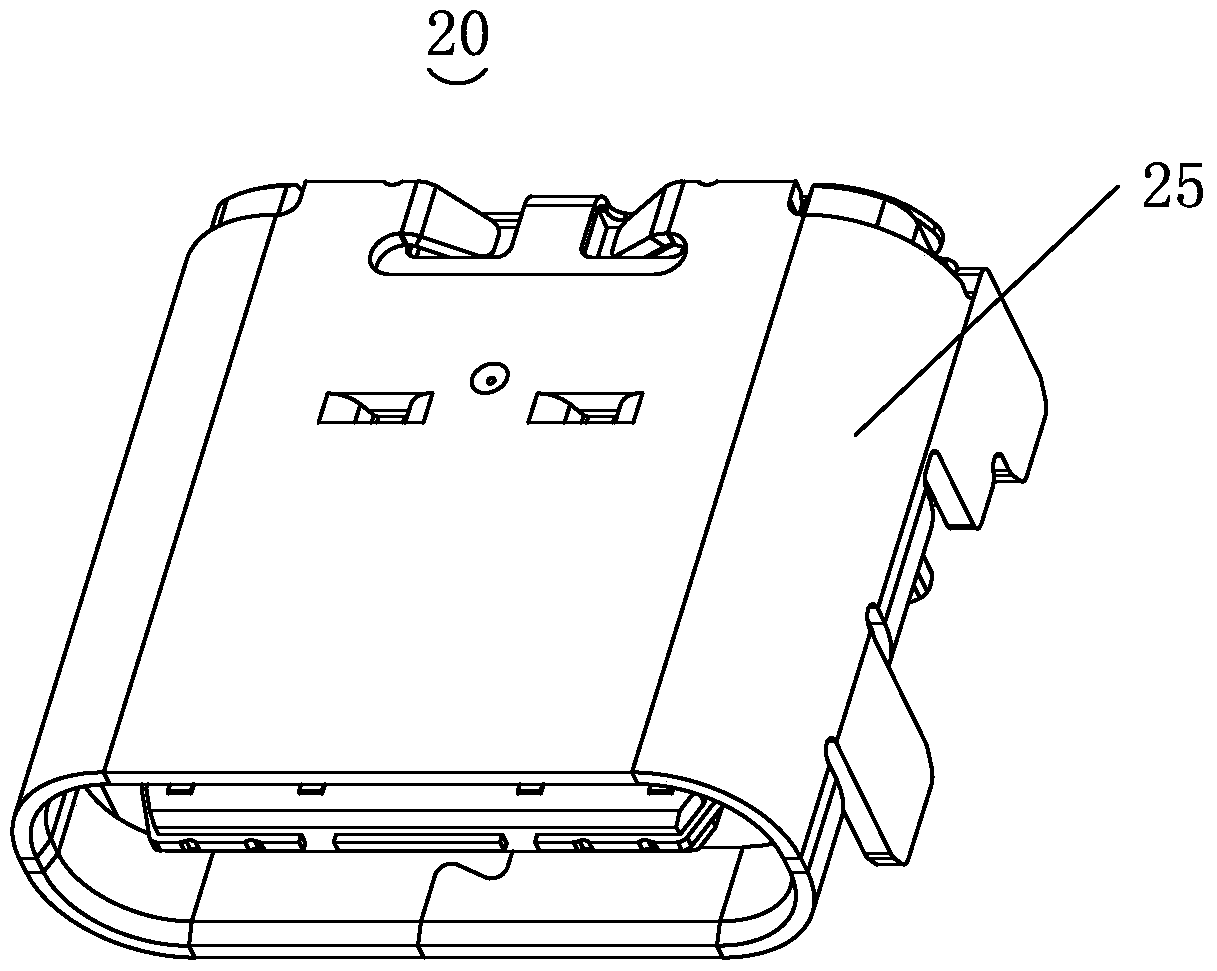

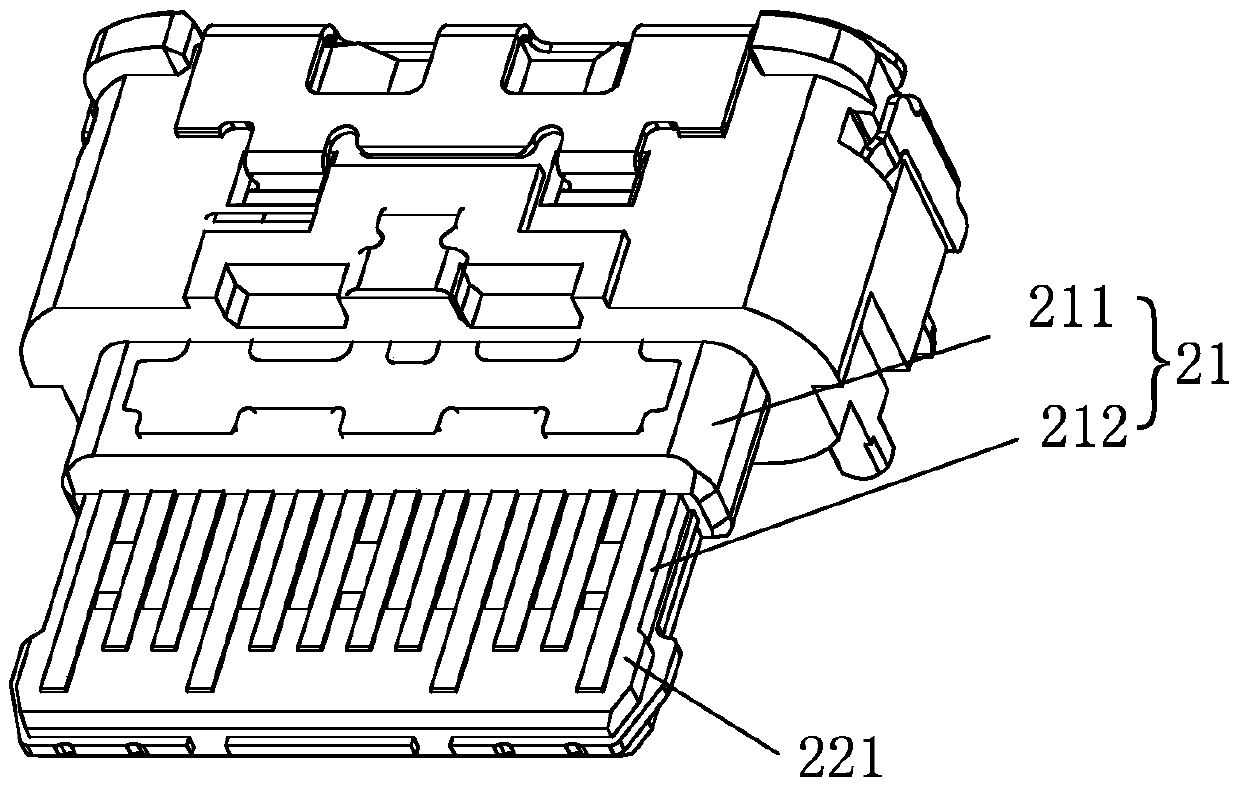

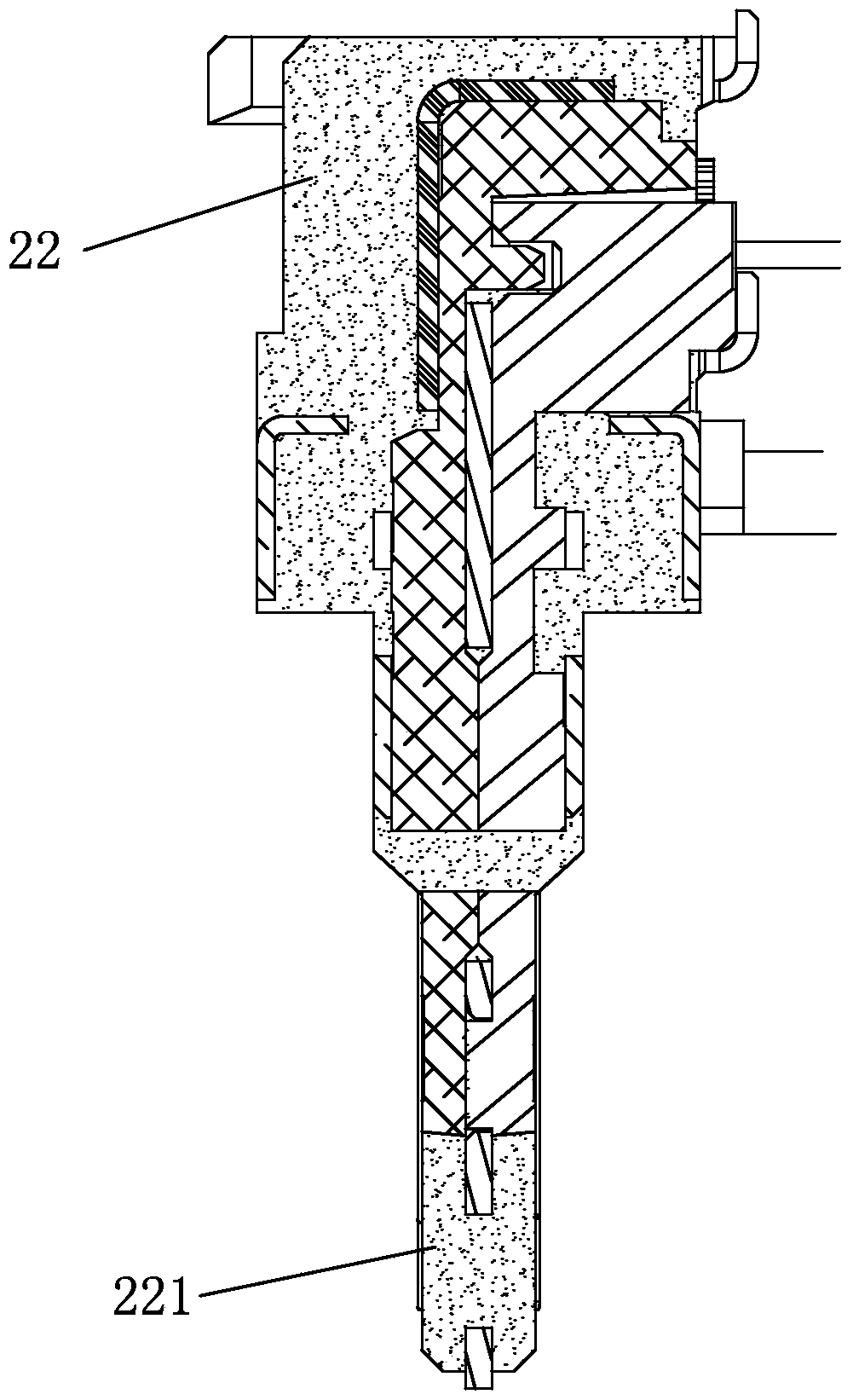

[0028] see Figure 1 to Figure 6 , the electrical connector 20 includes an insulating inner shell 21 , an insulating outer shell 22 , a first terminal 23 , a second terminal 24 and a metal shell 25 .

[0029] The insulating inner shell 21 includes a base 211 and a tongue 212 extending from the base 211 , wherein the tongue 212 is airtight. The insulating shell 22 wraps the outer surface of the insulating inner shell 21 , and the insulating shell 22 has a docking portion 221 extending toward the front end of the tongue plate 212 . It is worth noting that: the insulating shell 22 means that the plastic is heated and melted, and then coated on the surface of the insulating inner shell 21 to form a butt plate, while the airtight mentioned in this specification means that the insulating shell 22 does not extend to the tongue plate 212's interior. Further, the tongue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com