Printed circuit board and green-oil hole sealing process

A printed circuit and oil-sealed hole technology, which is applied in printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problem that the product is difficult to fully meet the customer's quality and appearance requirements, the sealing hole is easy to leak oil to other positions, and it is difficult to control the sealing Hole depth and other issues, to achieve the effect of not easy to deform, large amount of oil, and meet the requirements of sealing depth and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present application will be further elaborated below by way of examples.

[0026] In this embodiment, a green oil sealing process for a printed circuit board comprises the following steps:

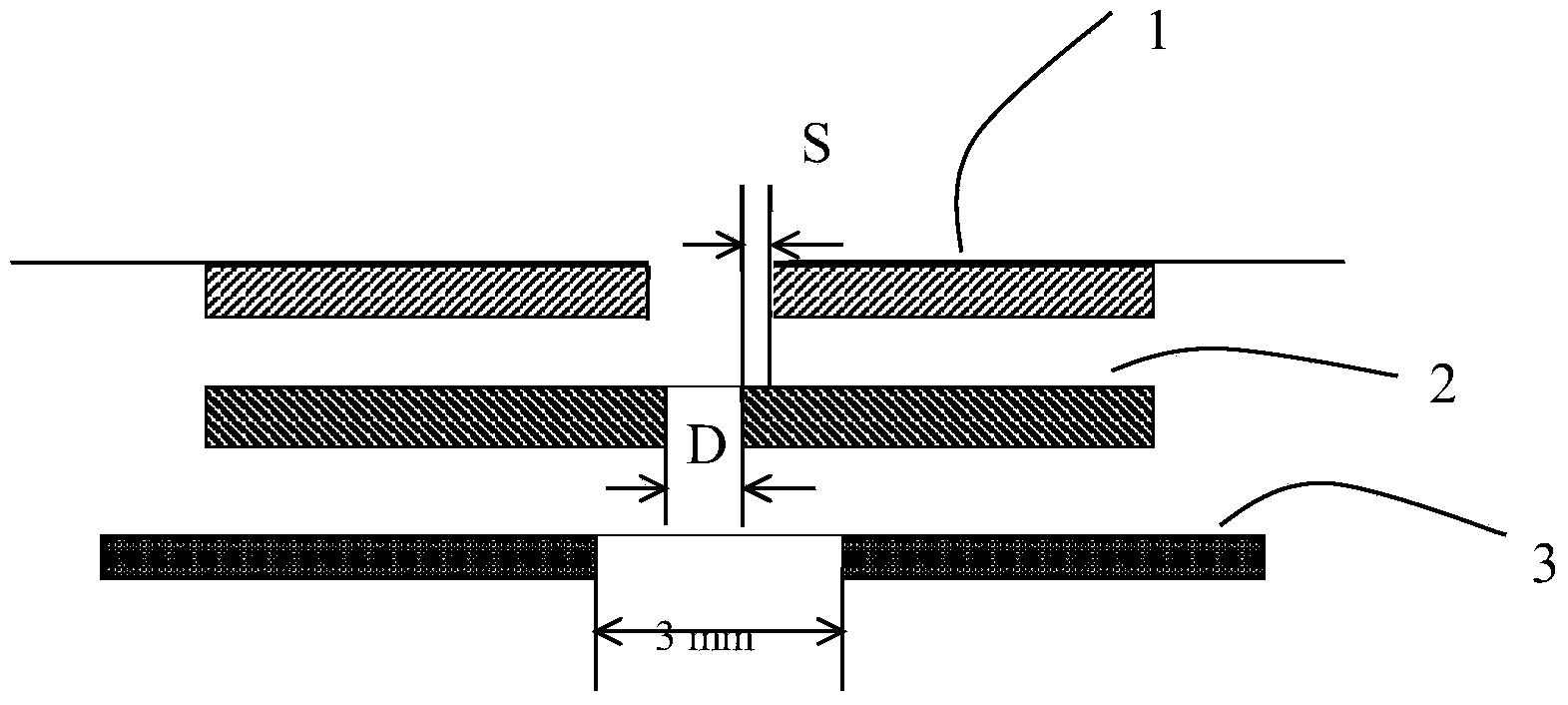

[0027] The production of the sealing bottom plate: the thickness of the sealing bottom plate is 1.0mm, the cutting size of the sealing bottom plate is 3 inches larger than each side of the sealing plate, and the hole is drilled in the area corresponding to the sealing position of the sealing plate, and the hole diameter is 3.0mm;

[0028] The area on the sealing base plate corresponding to the sealing position of the sealing plate is drilled, and the hole diameter is larger than the hole diameter of the sealing position, so that the air in the hole can be removed in time when the hole is sealed, and the formation of air bubbles in the hole will not affect the circuit board. Electrical performance.

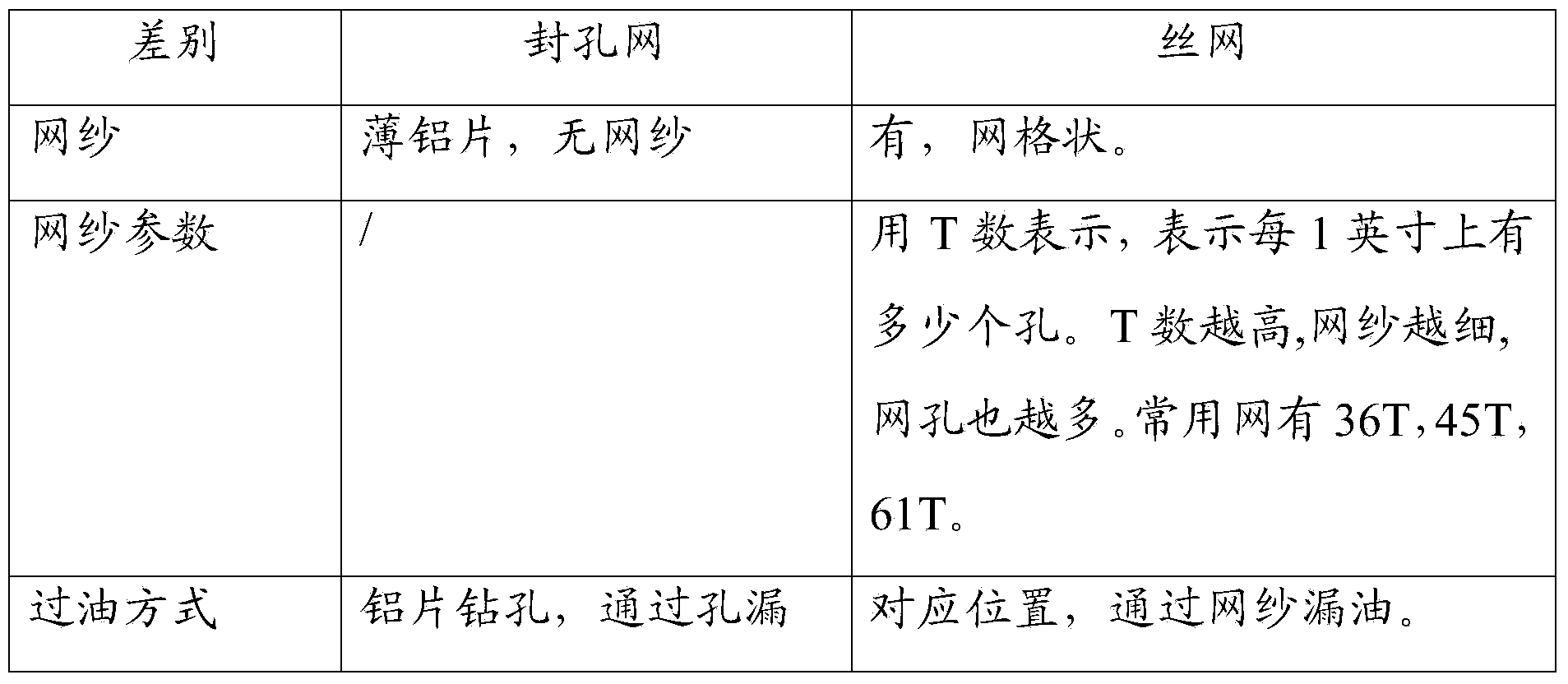

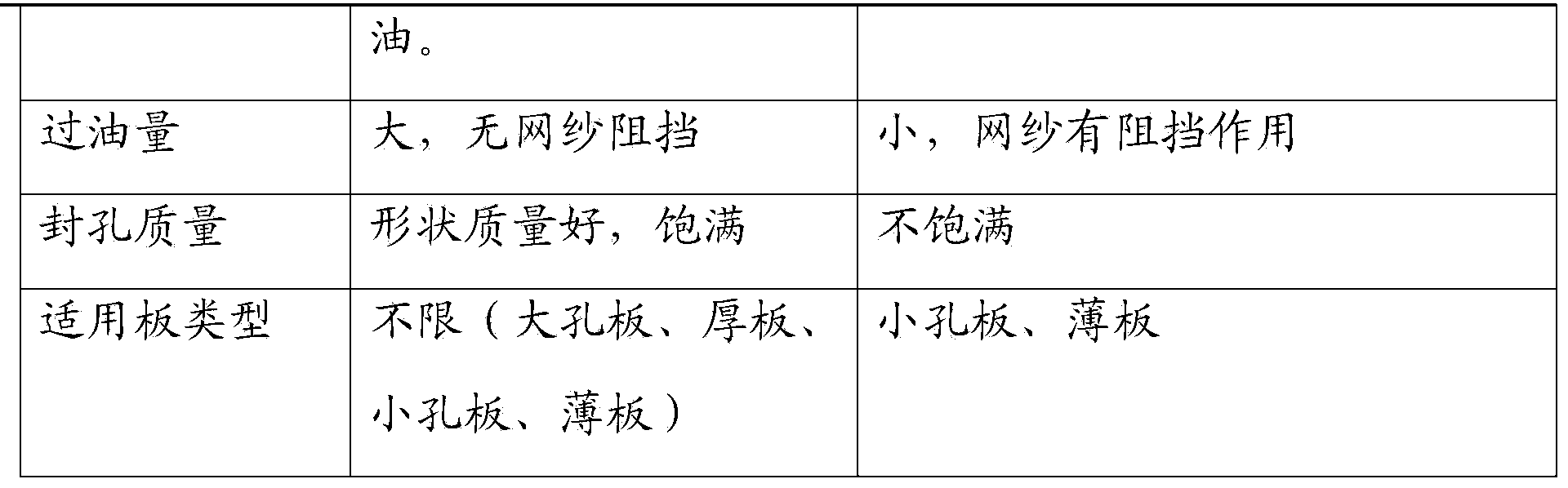

[0029] Production of the sealing mesh (made of aluminum sheet): the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com