Electric vehicle charging pile for automatically controlling and performing fire extinguishing

A technology for electric vehicles and charging piles, which is applied to electric vehicles, battery circuit devices, current collectors, etc., can solve the problems of inconvenient fire extinguishing, difficult fire extinguishing, and high fire occurrence rate, so as to achieve good fire extinguishing effect and ensure safe charging. , the effect of ensuring charging safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

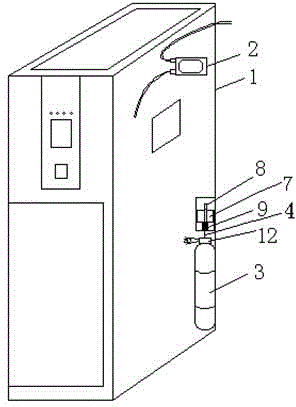

[0020] Such as Figure 1-3 As shown, an electric vehicle charging pile with automatic control and fire extinguishing includes a charging pile body 1 and a fire extinguisher 3 arranged inside the charging pile body 1. The charging pile body 1 is connected to a charging plug, and the charging plug is connected to the charging pile. A thermal protector 2 is connected between the main body 1, and the thermal protector 2 forms a parallel circuit with a 17AM1 thermal protector and a PTC, and then forms a series circuit with the charging pile body.

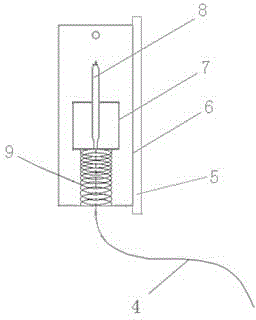

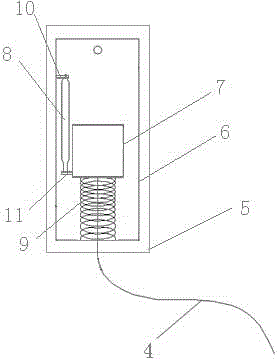

[0021] The start switch 12 of the fire extinguisher 3 is connected to the fire extinguishing switch through the steel wire rope 4, and the fire extinguishing switch includes a fire-fighting temperature-sensitive glass ball 8 and a shaft core 7 arranged in the casing 6, and a spring 9 is connected to the bottom end of the shaft core 7 , the bottom end of the spring 9 is connected to the bottom surface of the shell 6, and the top is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com