A vibration energy harvesting device

A vibration energy collection and vibrator technology, applied in electromechanical devices, electrical components, etc., can solve the problems of high magnetic flux leakage, low energy conversion rate, poor movement flexibility, etc., to improve utilization, eliminate positioning force, and ensure free movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

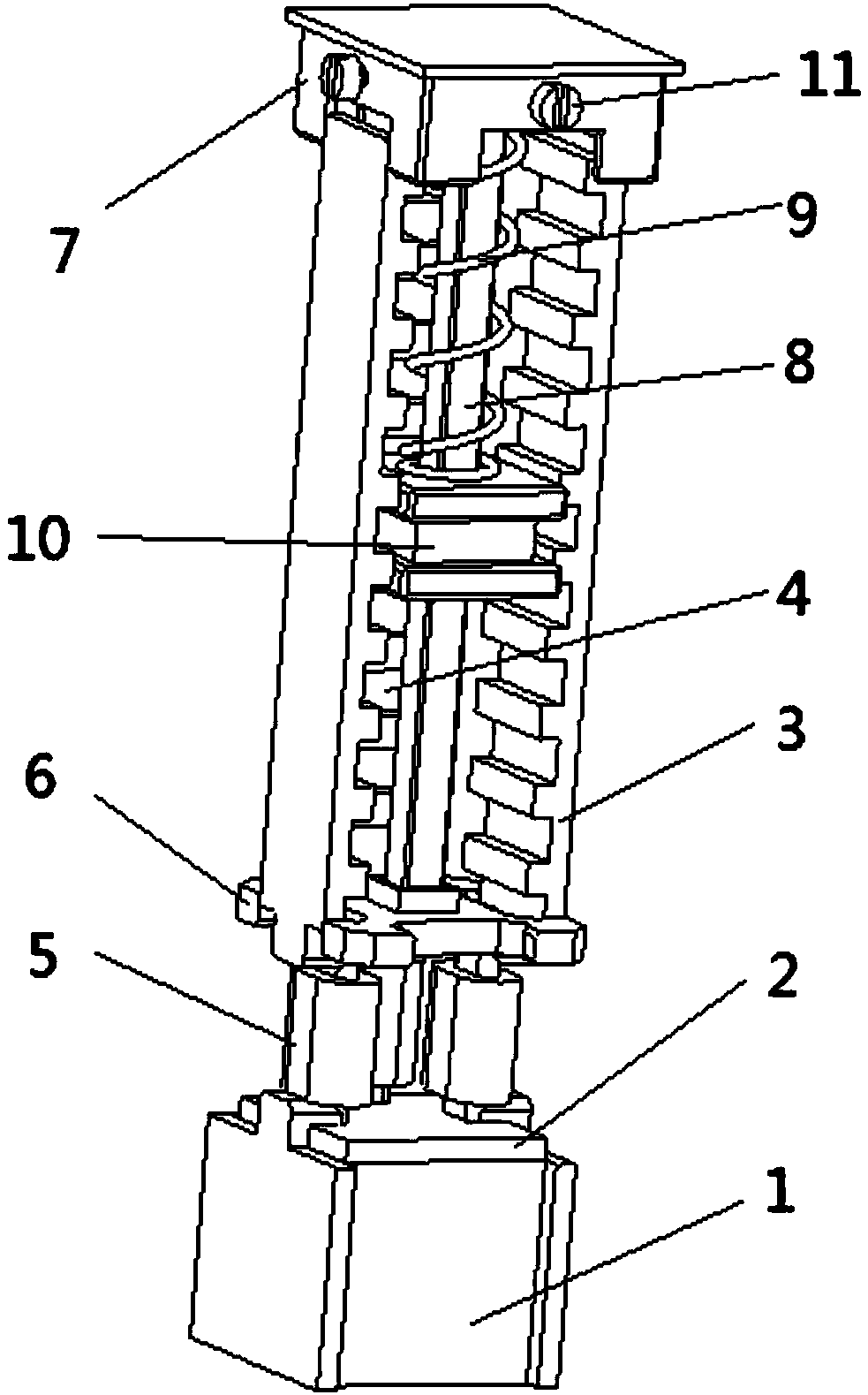

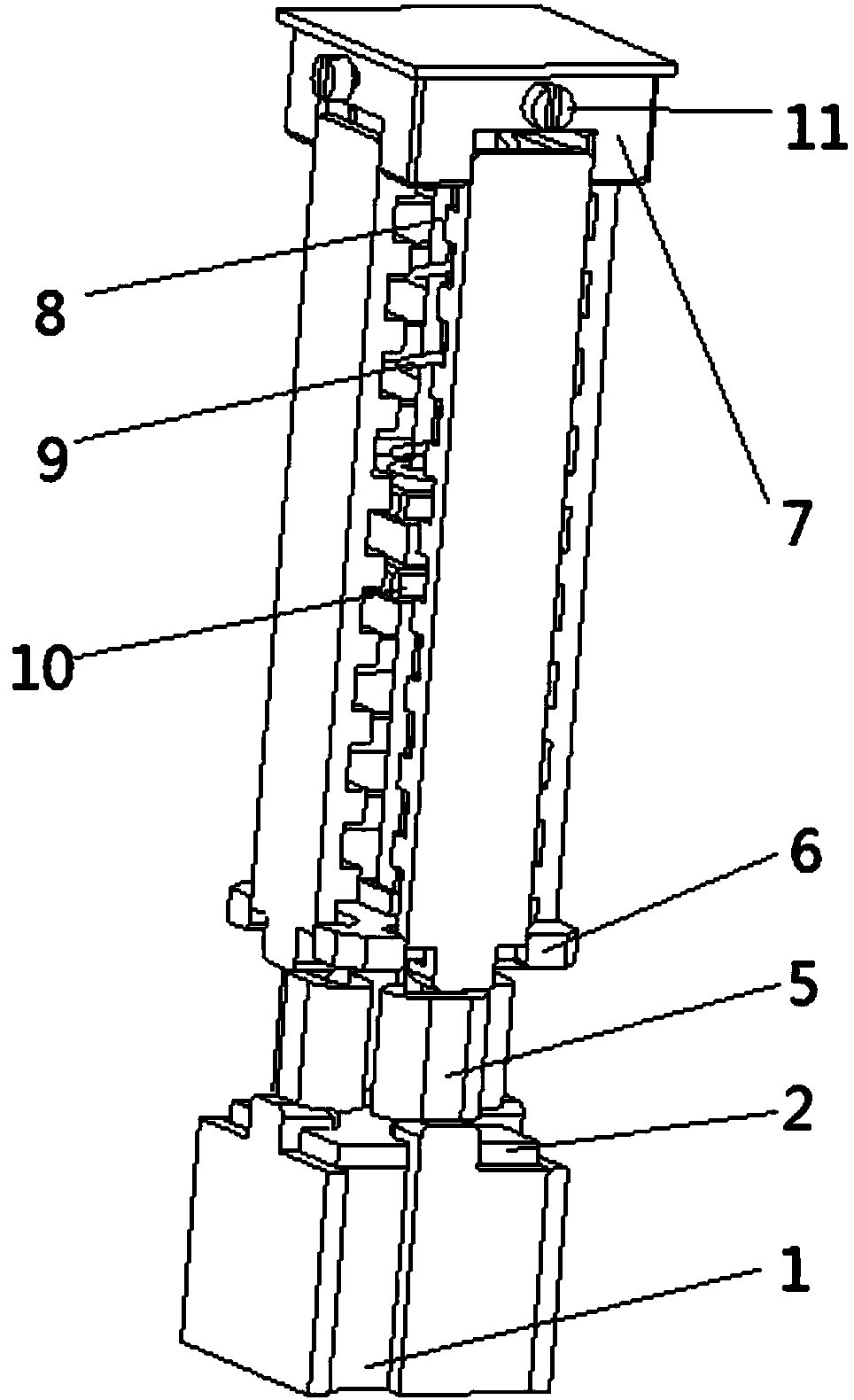

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] refer to Figure 1 ~ Figure 3 , a vibration energy harvesting device, comprising a housing 12, a permanent magnet 1 located in the housing 12, a left and right yoke 3, a front and rear yoke 4, a coil 5 and a ferromagnetic vibrator 10, the permanent magnet 1 includes an N pole and an S pole, so The permanent magnet 1 is lined with a rubber pad 2, and the N pole and S pole of the permanent magnet 1 are respectively placed on the left and right yokes 3, and the shape and size of the left and right yokes are completely consistent. The two sides of the permanent magnet 1 Part of the attached front and rear yokes 4, the yoke connected to the right yoke is the front yoke, the yoke connected to the left yoke is the rear yoke, the shape and size of the front and rear yokes are exactly the same, each yoke It includes a lower part, a middle part and a lower part, the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com