Multi-machine free moving mold changing vehicle

A mold car and mobile mechanism technology, applied in the field of mold changing cars, can solve the problems of lower production efficiency, easily damaged injection guns, inaccurate mold changing, etc., and achieve the effect of satisfying mold replacement, reducing risk factor, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

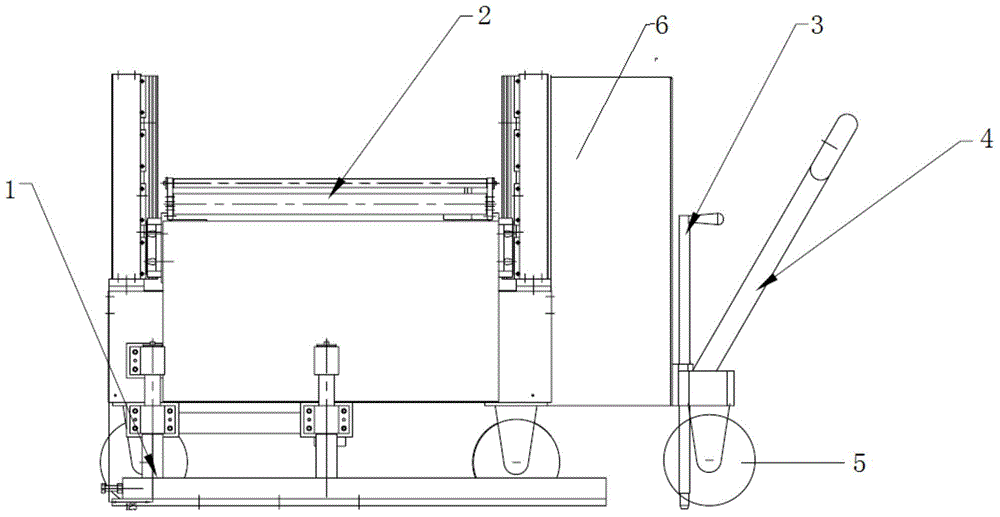

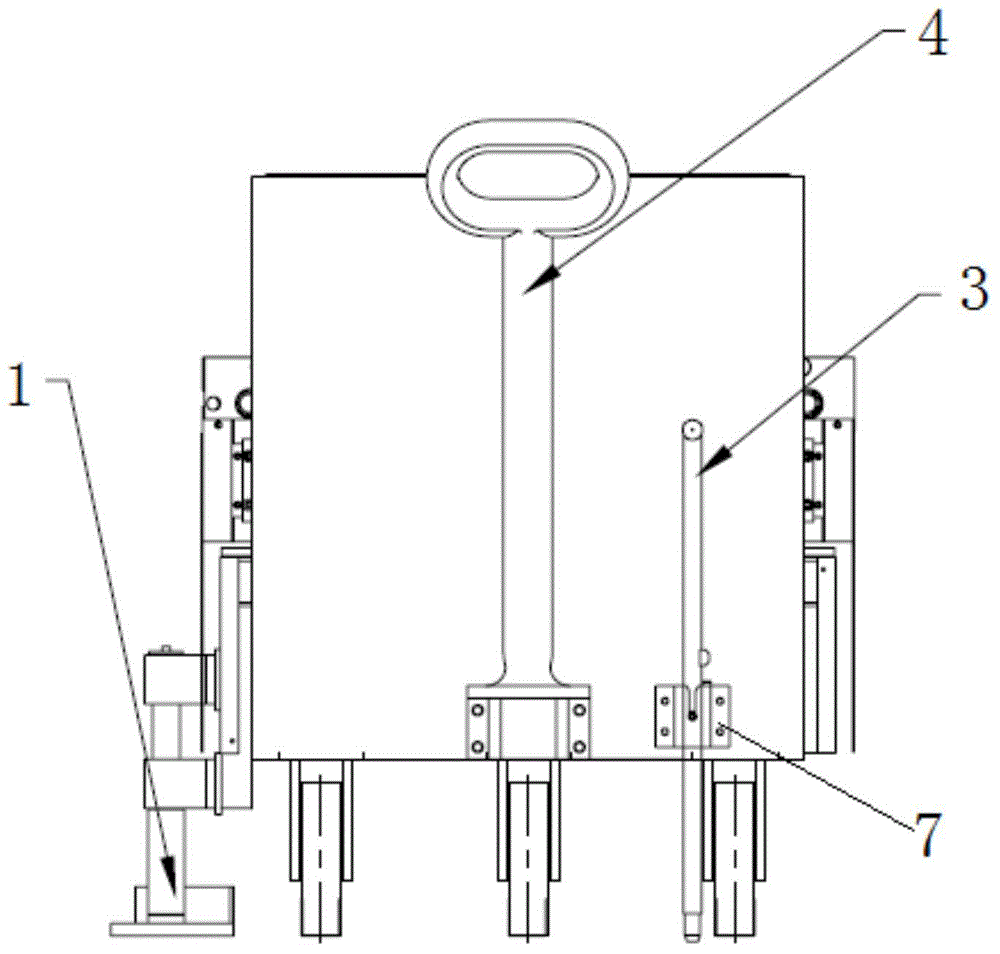

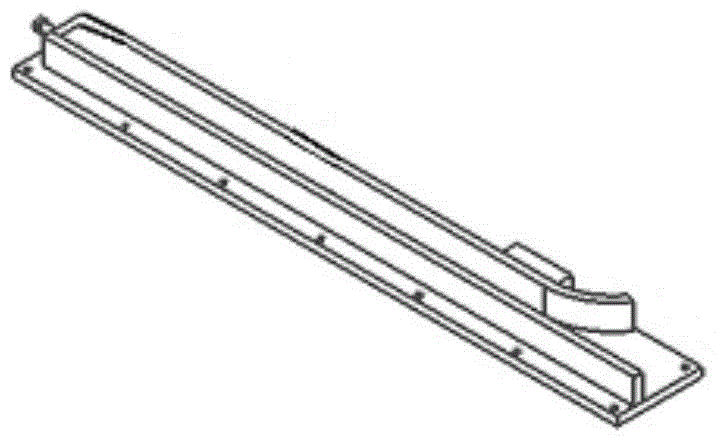

[0029] Such as Figure 1-4 As shown, the multi-machine mobile mold changing vehicle includes a rectangular parallelepiped frame, on which a moving mechanism, a lifting mechanism for lifting the conveying roller table and a positioning mechanism for positioning the mold changing vehicle and the injection molding machine are set. The mobile mechanism includes a storage battery, a first motor and wheels, the storage battery provides electric power to drive the wheels to rotate for the first motor, the wheels are arranged on the bottom of the vehicle frame, and a control box 6 is fixedly arranged on the vehicle frame, the storage battery, the first motor and the lifting mechanism The power source is set in the control box, and an operating rod is movably installed on one side of the control box. The bottom end of the operating rod is fixed on the side wall of the control box, and the movement of the mold changing vehicle is realized by manually moving the operating rod 4 and the wh...

Embodiment 2

[0035] The multi-machine mobile mold changing vehicle includes a rectangular parallelepiped frame, a moving mechanism, a lifting mechanism for lifting the conveying roller table and a positioning mechanism for positioning the mold changing vehicle and the injection molding machine on the frame; the moving mechanism It includes a storage battery, a first motor and wheels. The storage battery provides electric power for the first motor to drive the wheels to rotate. It is installed in the control box, and the operating rod is installed on one side of the control box. The bottom end of the operating rod is fixed on the side wall of the control box. The movement of the mold changing vehicle is realized by manually moving the operating rod 4 and the wheels. There are five wheels in total. One of them is set on the lower end of the operating rod 4 as the steering wheel 5, and the other four wheels are fixed below the vehicle frame and are directional wheels. The first motor drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com