Universal swinging type conveying belt error correcting device

A deviation correction device and conveyor belt technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large rotational resistance at the middle hinge, inflexible movement, and unstable swing of the swing roller frame, and achieve Space swing, improve the effect of deviation correction, and improve the effect of force condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

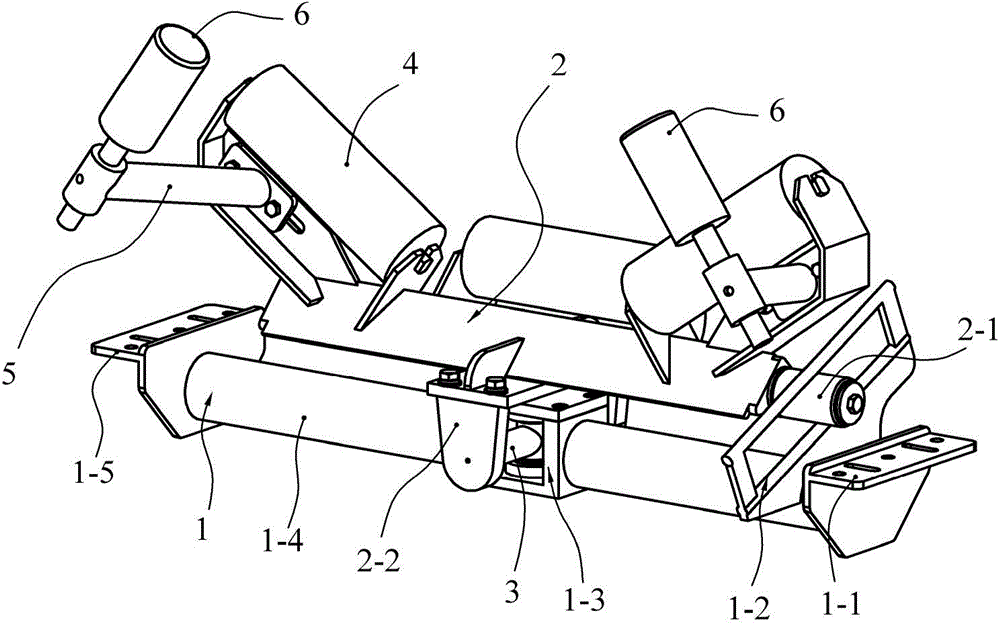

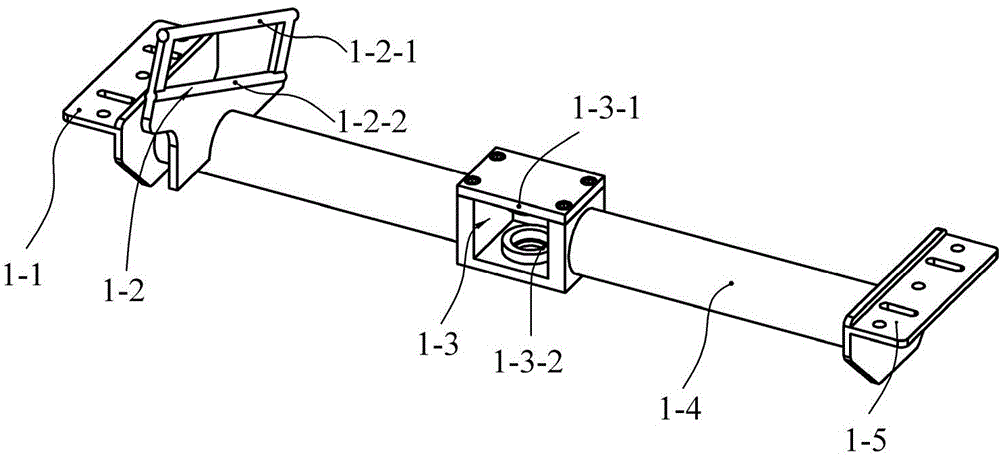

[0043] Refer to attached Figure 1 to Figure 7 .

[0044] The technical solution adopted by the present invention to solve its technical problems is:

[0045] Such as figure 1 As shown, the first embodiment of the universal swing conveyor belt correction device includes a bottom beam 1, a swing idler frame 2, an idler roller 4, a guide roller frame 5, and a guide roller 6, and the idler roller 4 is clamped on the swing idler frame 2, the guide rollers are symmetrically installed on both ends of one side of the swing roller frame 2 through the guide roller frame 5; Universal structure; the supporting connector 3 is hinged with the bottom beam 1 to form a rotating pair, and the supporting connecting member 3 is hinged with the swing idler frame 2 to form a rotating pair, and the axes of the two rotating pairs are orthogonal; the One end of the bottom beam 1 is provided with a longitudinal oblique guide unit, and one end of the swing roller frame 2 is provided with an end guid...

Embodiment 2

[0053] Refer to attached Figure 8 .

[0054] The structure of the second embodiment is similar to that of the first embodiment, the difference is that the oblique guide unit of the bottom beam 1 of the second embodiment adopts a helical curved groove 1-6, and the helical curved groove 1-6 includes an upper curved track 1-6-1 and the next track 1-6-2. The design of the spiral curved groove 1-6 can reduce the axial displacement of the guide roller 2-1 of the swing idler frame 2 relative to the inclined guide unit when moving in the spiral curved groove 1-6.

Embodiment 3

[0056] Refer to attached Figure 9 , 10 .

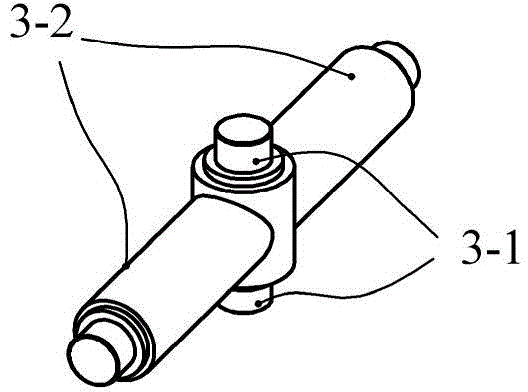

[0057] Figure 9 In the third embodiment shown, the swing idler frame 2 and the bottom beam 1 are connected together through the supporting connector 3 to form a universal structure. Such as Figure 10 As shown, the support connector 3 includes a vertical connector and a horizontal connector, and the vertical connectors are connected orthogonally in the middle of the horizontal connector to form a T-shaped structure; the vertical connector is a vertical half Axis 3-3, the horizontal connecting piece is the horizontal axis 3-2; the two ends of the bottom beam 1 are symmetrically provided with two longitudinal oblique guide units, and the oblique guide units adopt oblique guide rails, which are respectively denoted as oblique Guide rail one 1-7 and inclined guide rail two 1-9, described inclined guide rail is higher than the other end at one end in longitudinal direction; The middle part of described bottom beam 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com