Special compatibilizer and alloy for improving hydrolytic thermal stability of pc/abs alloy

A stability and compatibilizer technology, applied in the field of special compatibilizers and alloys, can solve the problems of black spots or gel points of materials, the need for master batches in use, insufficient heat resistance, etc., and achieve high use efficiency and high use Low cost, good cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

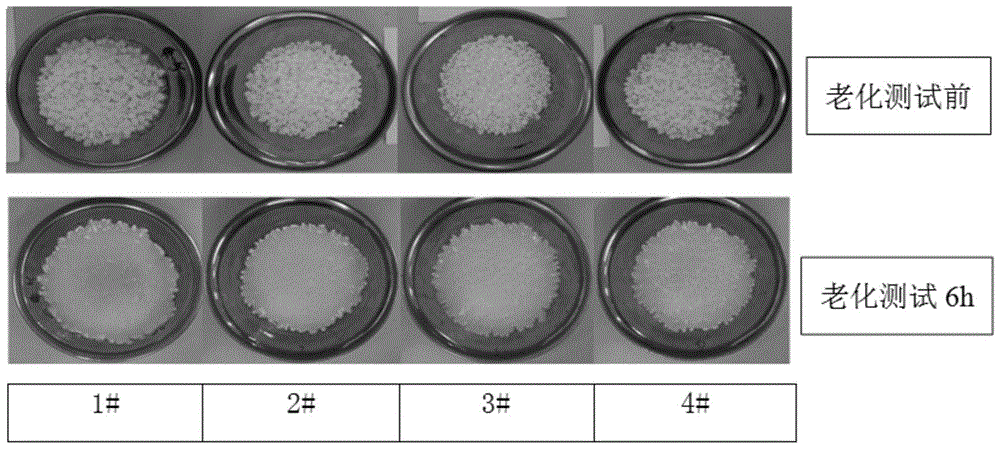

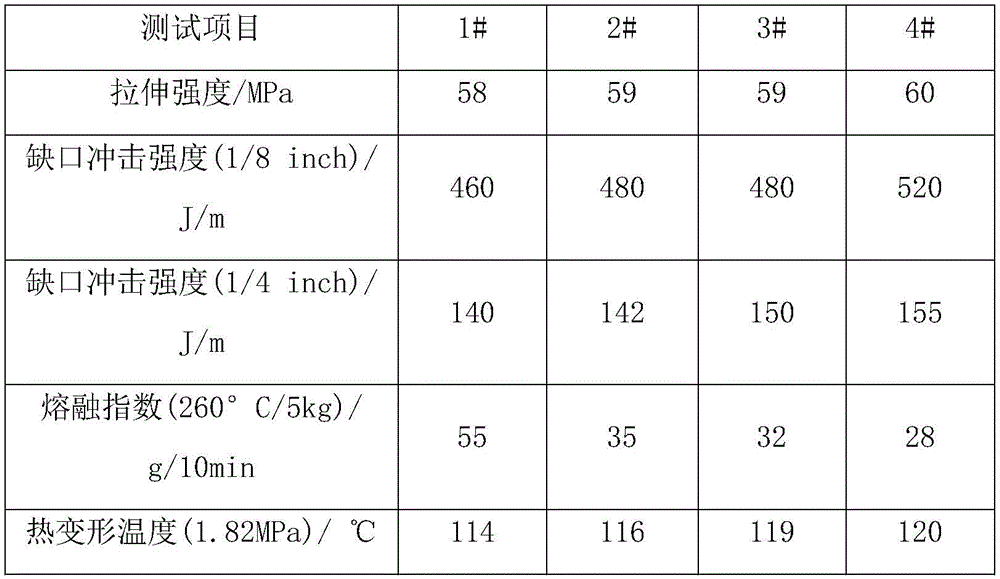

Embodiment 1~4

[0034] The PC resin is PCI250WP (the relative number average molecular weight is 22,000g / mol, and the glass transition temperature is 140°C) from Teijin Corporation of Japan; the ABS resin is P / D190 (the relative weight average molecular weight is 120,000g / mol , wherein the weight percentage content of butadiene is 50%, the weight percentage content of acrylonitrile is 15%, and the weight percentage content of styrene is 35%.

[0035] Table 1 Raw materials and proportions of Examples 1 to 4

[0036] raw material name Example 1 (wt%) Example 2 (wt%) Example 3 (wt%) Example 4 (wt%) PC 70 70 70 70 ABS 29.3 28.8 28.3 27.3 ST-AN-6MA Terpolymer 1 0 0.5 1 2 antioxidant 0.3 0.3 0.3 0.3 lubricant 0.4 0.4 0.4 0.4

[0037] Put the above components into the high mixer according to the proportion and mix them for 1-5 minutes, discharge the material, then extrude and granulate with a screw extruder, the processing temperature ...

Embodiment 5~7

[0046] The PC resin is PCI250WP (the relative number average molecular weight is 22,000g / mol, and the glass transition temperature is 140°C) from Teijin Corporation of Japan; the ABS resin is P / D190 (the relative weight average molecular weight is 120,000g / mol , wherein the weight percentage content of butadiene is 50%, the weight percentage content of acrylonitrile is 15%, and the weight percentage content of styrene is 35%.

[0047] Table 3 Raw materials and proportioning of Examples 5-7

[0048] raw material name Example 5 (wt%) Embodiment 6 (wt%) Example 7 (wt%) PC 70 70 70 ABS 28.8 28.8 28.8 ST-AN-GMA Terpolymer 2 0.5 ST-AN-GMA Terpolymer 3 0.5 SMA 0.5 antioxidant 0.3 0.3 0.3 lubricant 0.4 0.4 0.4

[0049] Put the above components into the high mixer according to the proportion and mix them for 1-5 minutes, discharge the material, then extrude and granulate with a screw extruder, the process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com