Supply apparatus and sewing system

A technology for supplying devices and placing parts, applied to sewing equipment, sewing machine components, textiles and papermaking, etc., to achieve the effect of suppressing deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

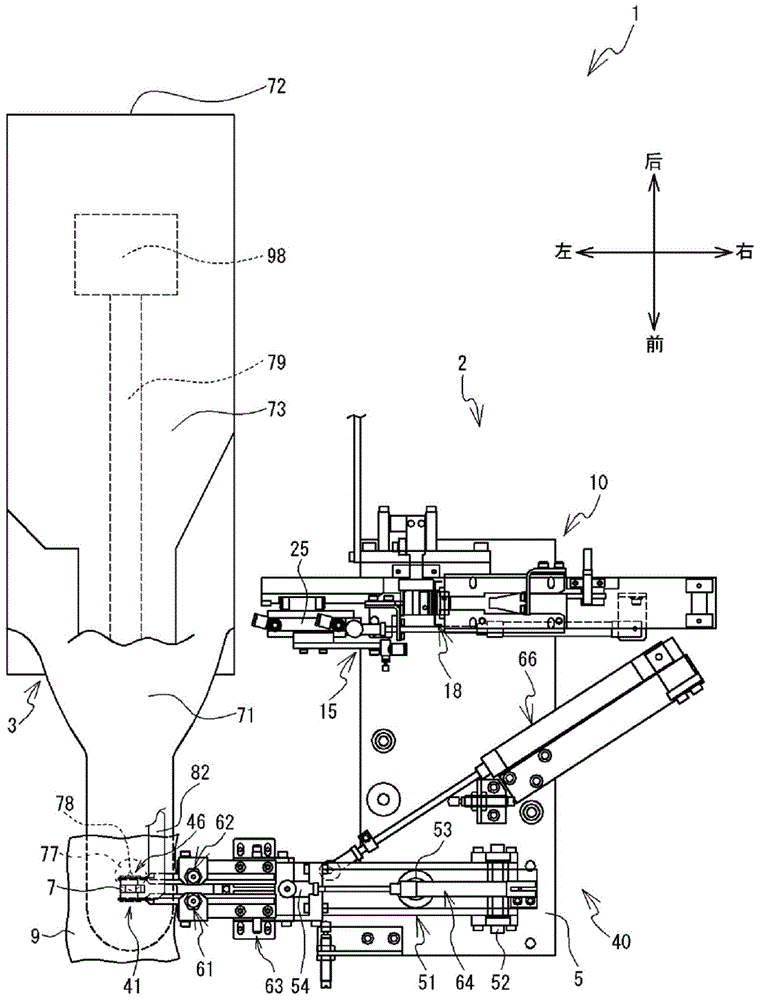

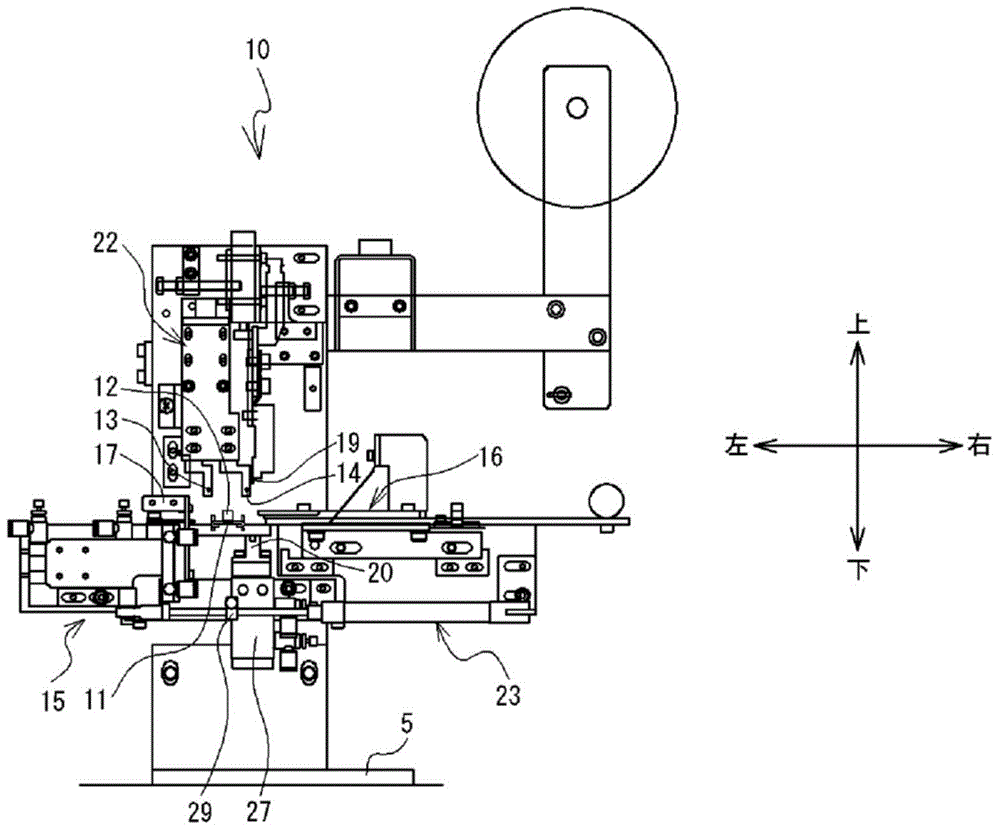

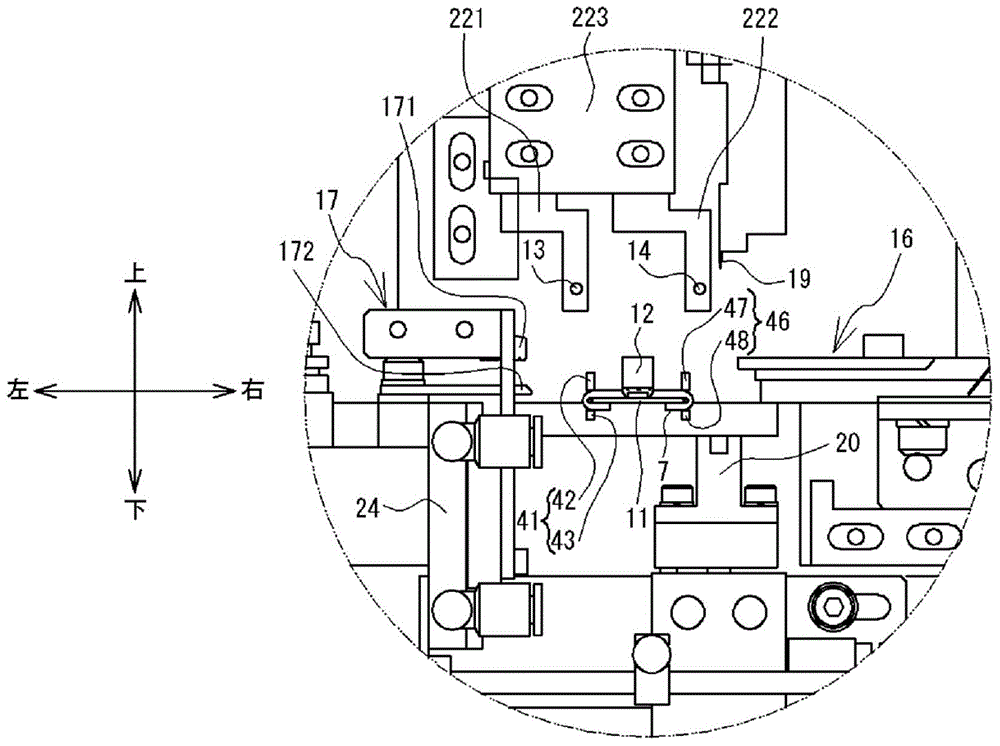

[0042] One embodiment of the present invention will be described with reference to the drawings. refer to Figure 1 ~ Figure 3 The configurations of the sewing system 1 , the loop piece supply device 2 and the sewing machine 3 will be described. In the following description, up and down, left and right, and front and rear indicated by arrows in the figure are used.

[0043] The sewing system 1 produces a strap piece 7 for thread-like members to pass through. Then, the sewing system 1 sews the strap piece 7 to the object to be sewed (cloth or leather). The sewing system 1 includes a belt piece supply device 2 and a sewing machine 3 . The strap sheet 7 is a belt-shaped member 8 (refer to Figure 11 ) is a member formed by bending the strip-shaped member 8 in the longitudinal direction. The loop piece supply device 2 bends both ends of the belt-shaped member 8 in the longitudinal direction, respectively, to manufacture the loop piece 7 . The loop piece supply device 2 suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com