Shear-reinforced structure of steel beams

A technology for strengthening structures and steel beams, applied in truss structures, joists, girders, etc., can solve problems such as large thickness, difficulty in procurement and welding, and impact on building functions, so as to improve shear bearing capacity and avoid procurement and welding. The effect of difficult, simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

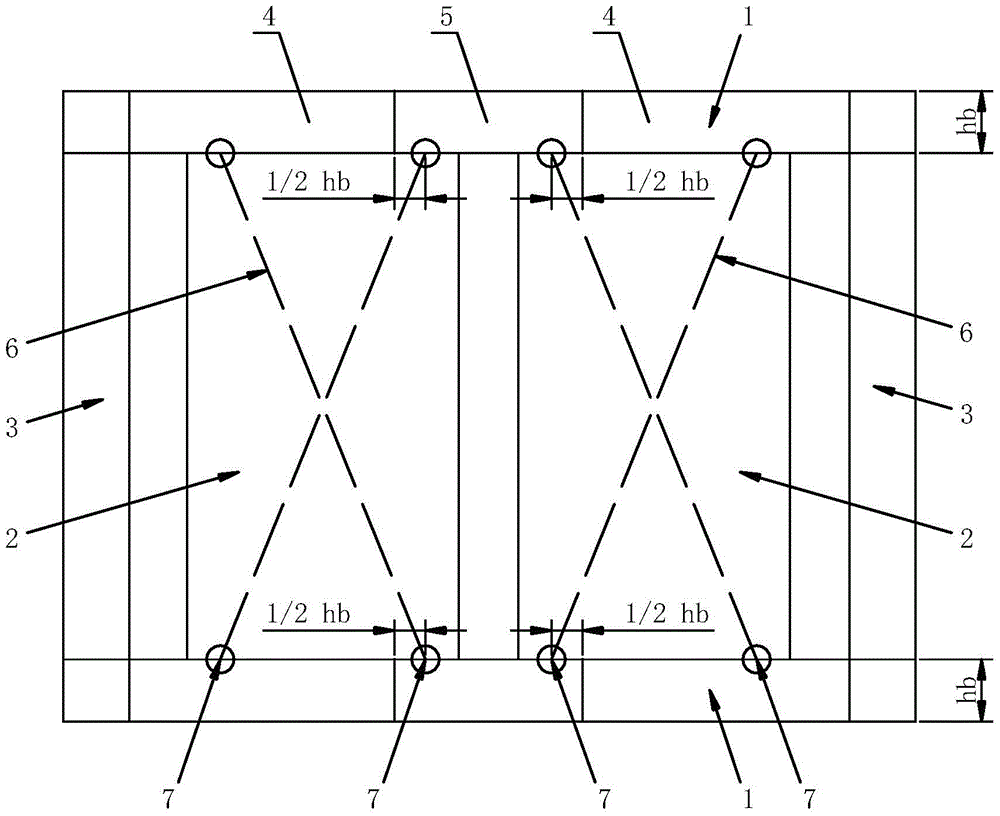

Embodiment 1

[0045] According to the requirement of shear bearing capacity, the required thickness δ of the corrugated steel plate is more than 20 mm.

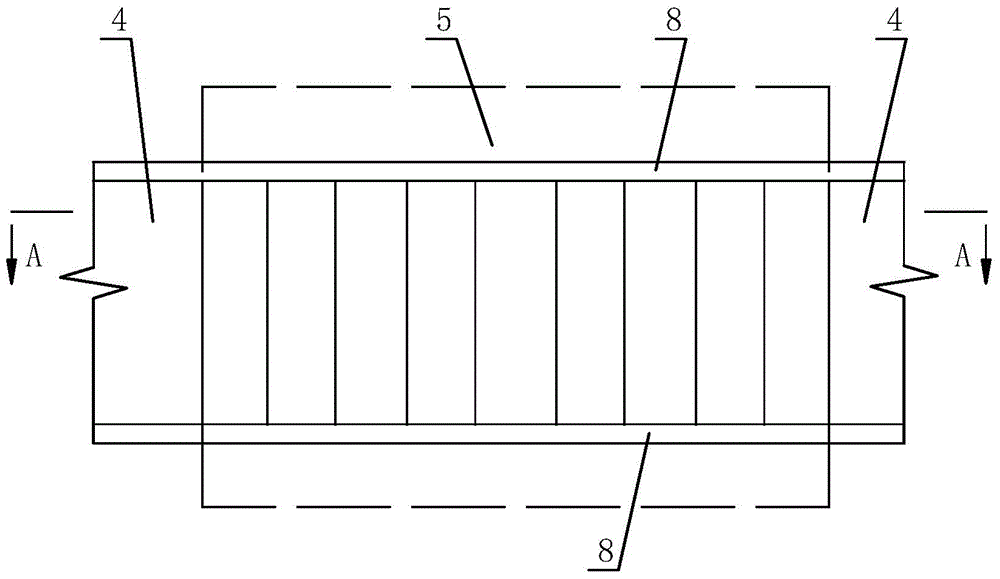

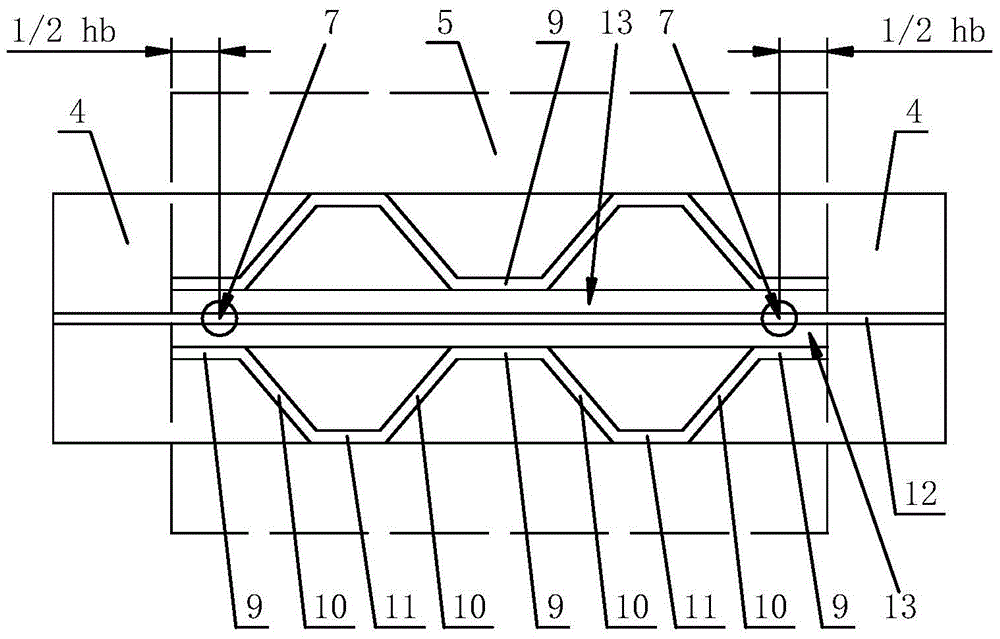

[0046] Then, if figure 2 , image 3 As shown, on both sides of the web 12 of the shear strengthening section 5, a flat steel plate 13 is welded closely to each other, and the thickness of the flat steel plate 13 is 1 / 3δ; then the corrugated steel plate is arranged on the flat steel plate 13 The outer side of the corrugated steel plate, the actual thickness of the corrugated steel plate is 1 / 6δ (in a word, the actual thickness of the corrugated steel plate is not greater than 20mm), so that the first horizontal section 9 of the corrugated steel plate is welded close to the flat steel plate 13, so that The oblique section 10 of the corrugated steel plate is welded to the two flanges 8 of the shear strengthening section 5; and the second horizontal section 11 of the corrugated steel plate is located inside the flange 8 of the shear strength...

Embodiment 2

[0048] According to the requirement of shear bearing capacity, the required thickness δ of the corrugated steel plate is not greater than 20mm.

[0049] Then, the actual thickness of the corrugated steel plate is the required thickness δ; figure 2, Figure 4 As shown, the corrugated steel plate is arranged on both sides of the web 12 of the shear strengthening section 5, and at the point 7 of the vertical resultant force, the first horizontal section 9 of the corrugated steel plate is close to the The web 12 of the steel beam 1 is welded; the oblique section 10 of the corrugated steel plate is welded to the two flanges 8 of the shear reinforcement section 5; and the second horizontal section 11 of the corrugated steel plate is located at the The inside of the flange 8 of the shear reinforcement section 5 is welded with the second horizontal section 11 and the two flanges 8 of the shear reinforcement section 5 .

[0050] The shear strengthening structure of steel girders of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com