Main blade connecting arm for test table

A technology for connecting arms and main blades, which is applied in the field of inspection of helicopter main blades, can solve the problems of time-consuming and high cost, and achieve the effect of saving refitting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

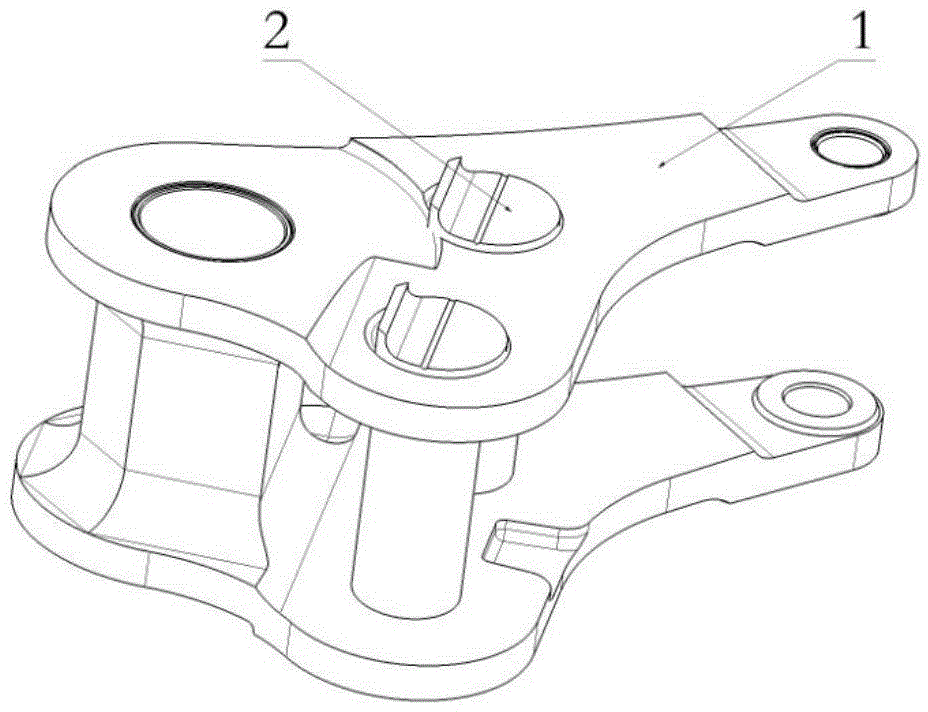

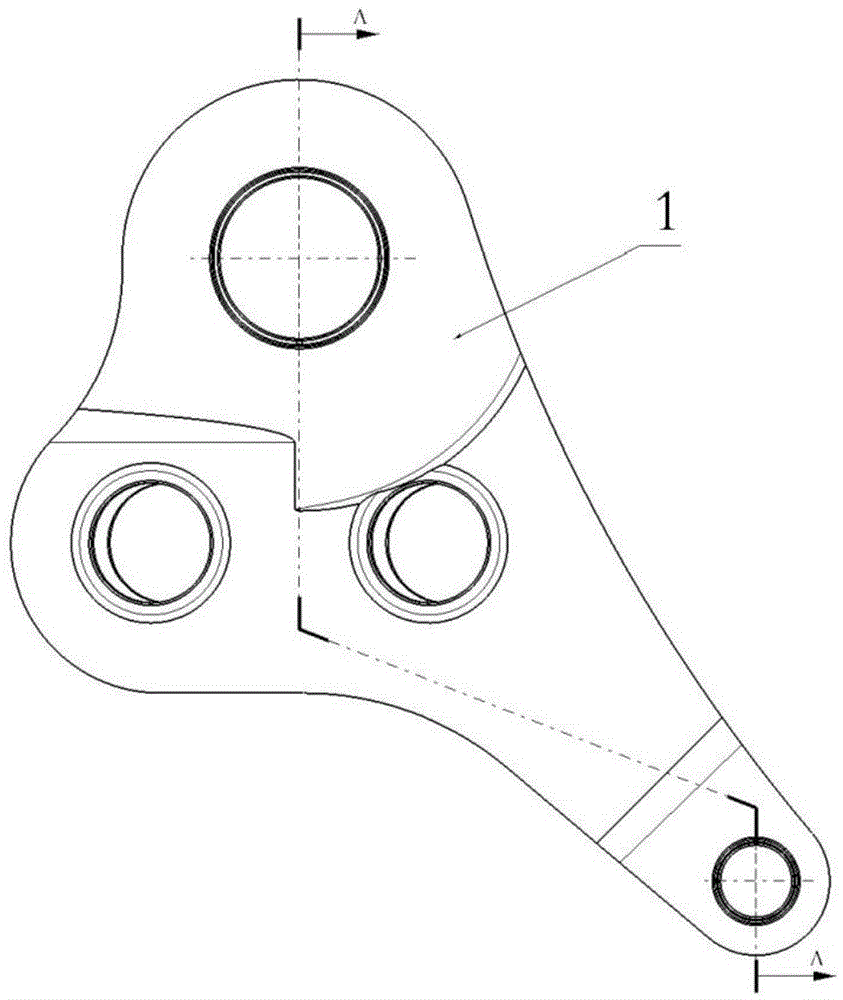

[0028] as in the present invention Figure 1-13 , the main blade connecting arm of the test bench of the present invention is mainly used for the connection and installation of the three-blade hub helicopter rotor system and the new blade, and is divided into two parts: the connecting arm (1) and the blade mounting pin:

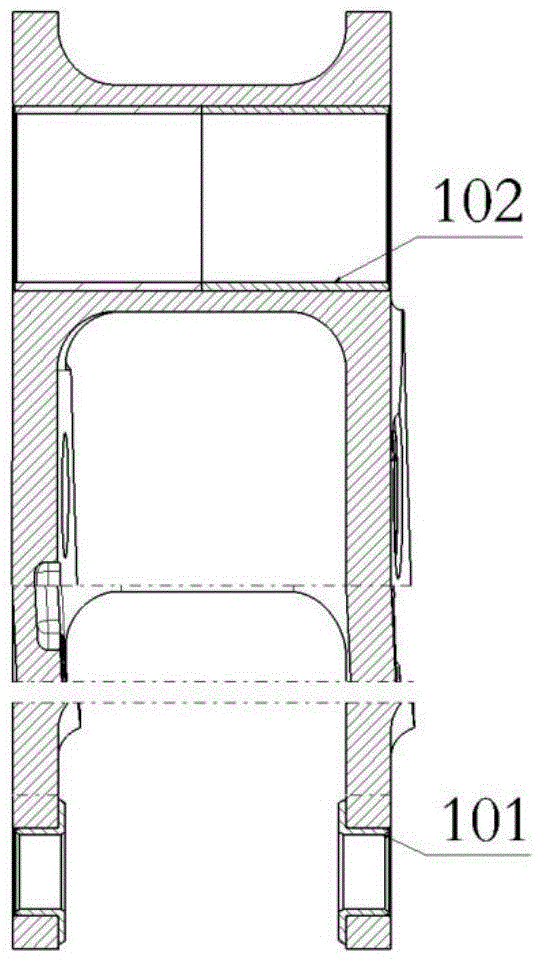

[0029] The connecting arm (1) is processed from a piece of metal, one end of the connecting arm (1) is installed on the propeller hub, and a propeller hub mounting hole of the same size is processed on the connecting arm (1) according to the propeller mounting hole of the propeller hub, In order to adapt to the installation of the propeller hub, the corners of the upper and lower surfaces of the hub mounting hole of the connecting arm (1) need to form a certain angle with the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com