Array substrate, preparation method of array substrate, display panel and display device

A technology for array substrates and substrates, applied in optics, instruments, electrical components, etc., can solve problems such as poor light leakage in the screen, inability to cover the interval area 6, and offset in the long side direction of pixels, and achieve the effect of avoiding poor light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

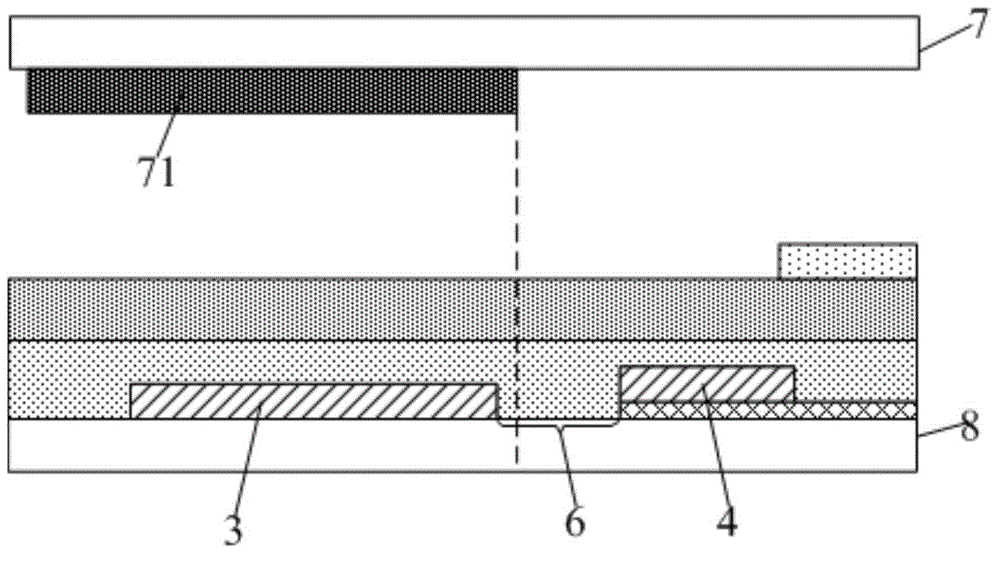

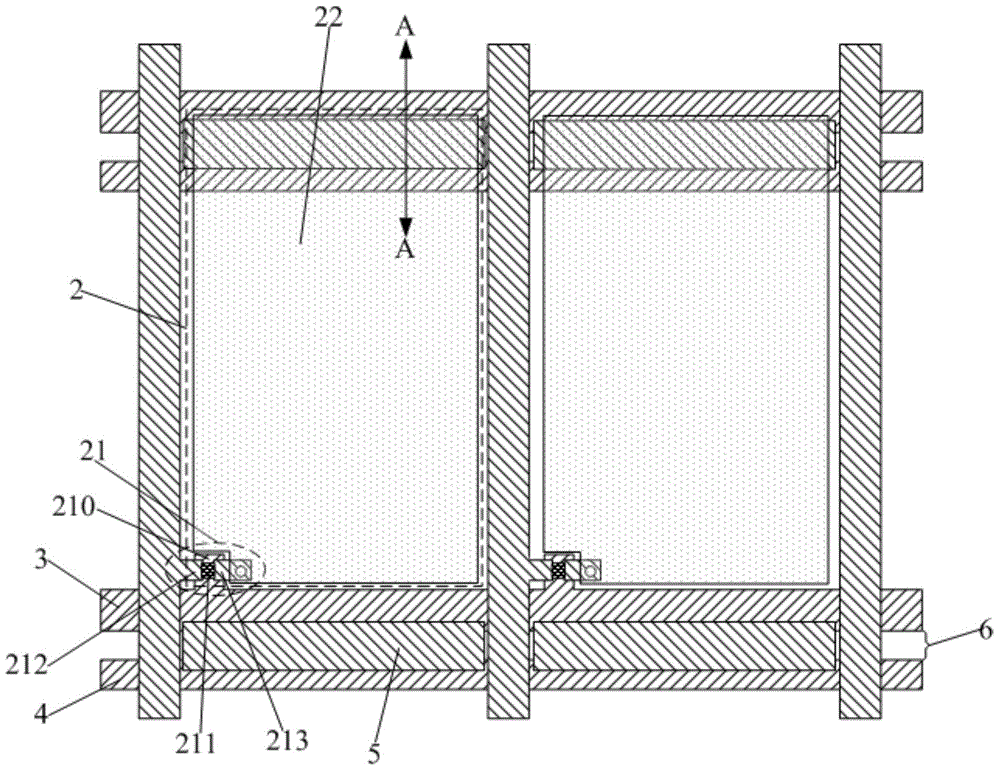

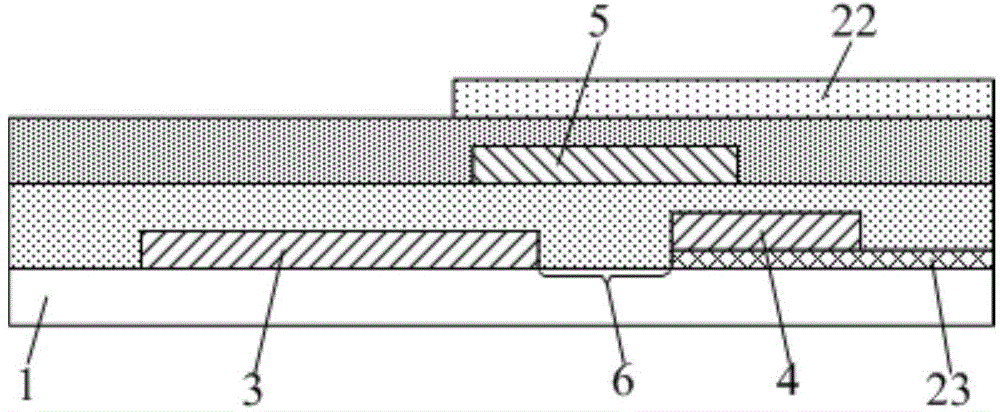

[0031] This embodiment provides an array substrate, such as figure 2 and image 3 As shown, it includes a substrate 1 and a plurality of pixel units 2 arranged in an array arranged on the substrate 1, a plurality of gate lines 3 and a plurality of common electrode lines 4, and each row of pixel units 2 corresponds to one gate line 3 and one common electrode line. The electrode lines 4, the gate lines 3 and the common electrode lines 4 corresponding to the pixel units 2 in each row are located on the same side of the pixel units 2 in each row, and are parallel to and spaced from each other, and also include a light-shielding strip 5, which is connected with the gate line 3 and the common electrode. The spacing regions 6 between the lines 4 correspond to each other, and the orthographic projection of the light-shielding strip 5 on the substrate 1 shields the spacing regions 6 .

[0032] The array substrate can shield the space region 6 between the gate line 3 and the common el...

Embodiment 2

[0046] This embodiment provides an array substrate. The difference from Embodiment 1 is that the pixel unit further includes a pixel electrode and a common electrode, the pixel electrode is arranged above the common electrode, the common electrode is arranged above the light-shielding strip, and the common electrode completely covers the light-shielding strip .

[0047] Such setting enables the common electrode to effectively shield the electric field between the light-shielding strip and the grid line and the common electrode line, so that the liquid crystal molecules correspondingly distributed in this area during display will not be disordered or the degree of disorder will be reduced. Furthermore, it is ensured that the electric field between the light-shielding strips, the grid lines and the common electrode lines will not affect the normal display.

[0048] The array substrate in this embodiment is also an array substrate in an ADS mode (Advanced Super Dimensional Field ...

Embodiment 3

[0054] This embodiment provides an array substrate. The difference from Embodiment 1-2 is that the pixel unit further includes a pixel electrode and a common electrode, the common electrode is arranged above the pixel electrode, the pixel electrode is arranged above the light-shielding strip, and the pixel electrode completely covers the Blackout strips.

[0055] Such setting also enables the pixel electrodes to effectively shield the electric field between the light-shielding strips, the gate lines and the common electrode lines, so that the liquid crystal molecules correspondingly distributed in this area will not be disordered or the degree of disordering will be reduced during display. , so as to ensure that the electric field between the light-shielding strips, the grid lines and the common electrode lines will not affect the normal display.

[0056] The array substrate in this embodiment is also an array substrate in an ADS mode (Advanced Super Dimensional Field Switchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com