Barrier-crossing mechanism of transmission line deicing robot

A technology of power transmission lines and robots, applied in the installation of cables, electrical components, overhead installation, etc., can solve the problems of high requirements for distance and angle, high cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

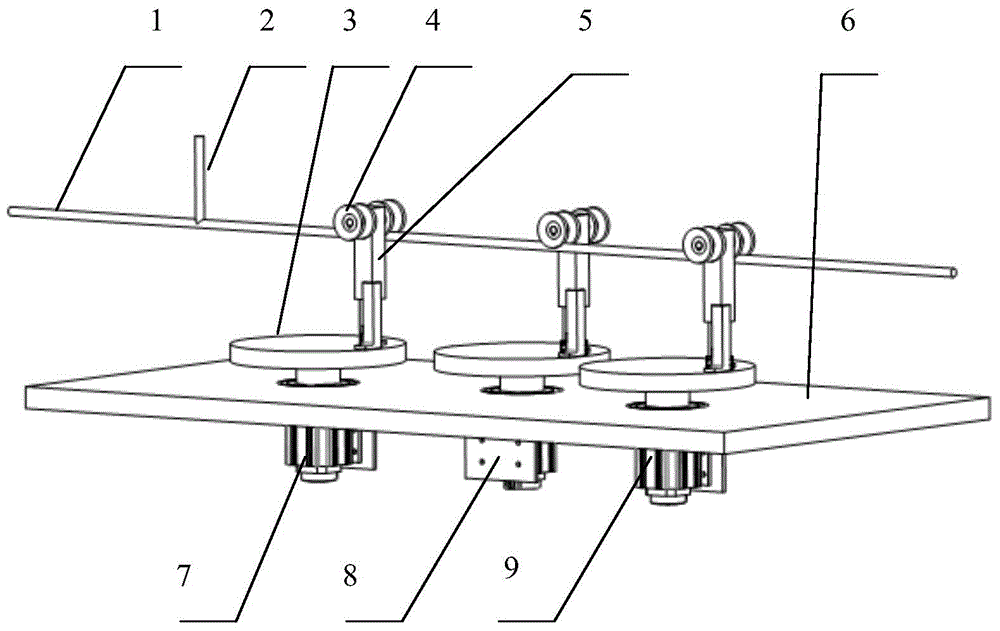

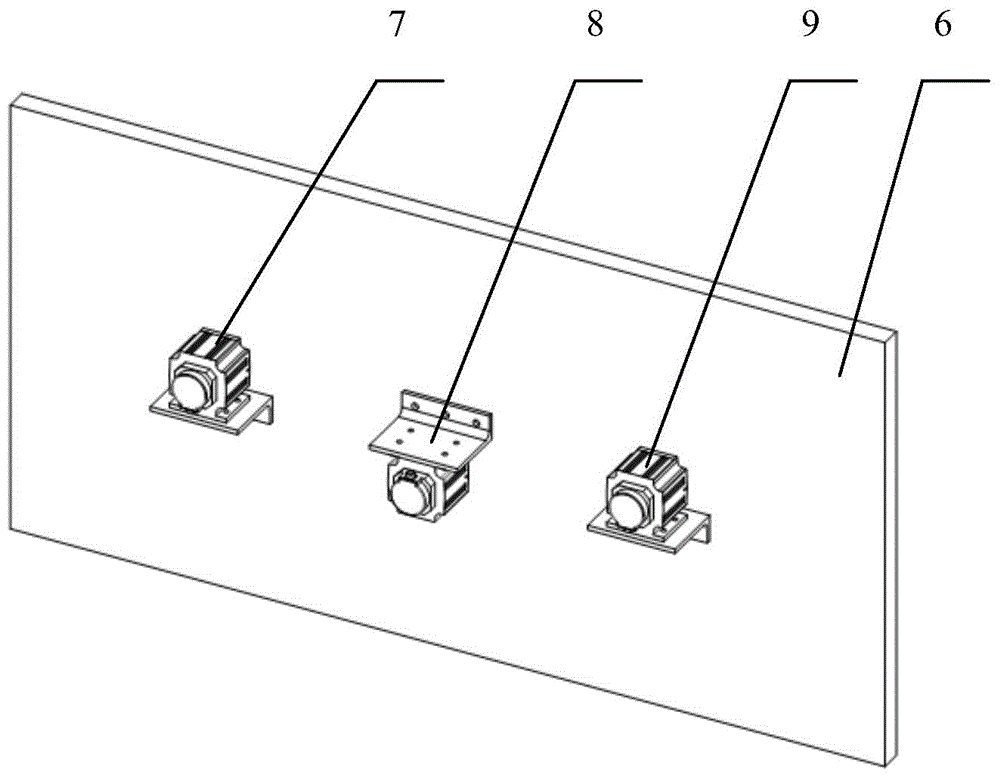

[0022] Such as figure 1 As shown, the obstacle surmounting mechanism of the present invention includes three sets of independent operation front and rear obstacle surmounting devices composed of a lifting device and a rotating device. On the rotating disk 3 of the rotating device, the rotating disk 3 of the rotating device is connected with the rotating motor 7 arranged on the fixed plate 6 to realize the rotation of the rotating disk;

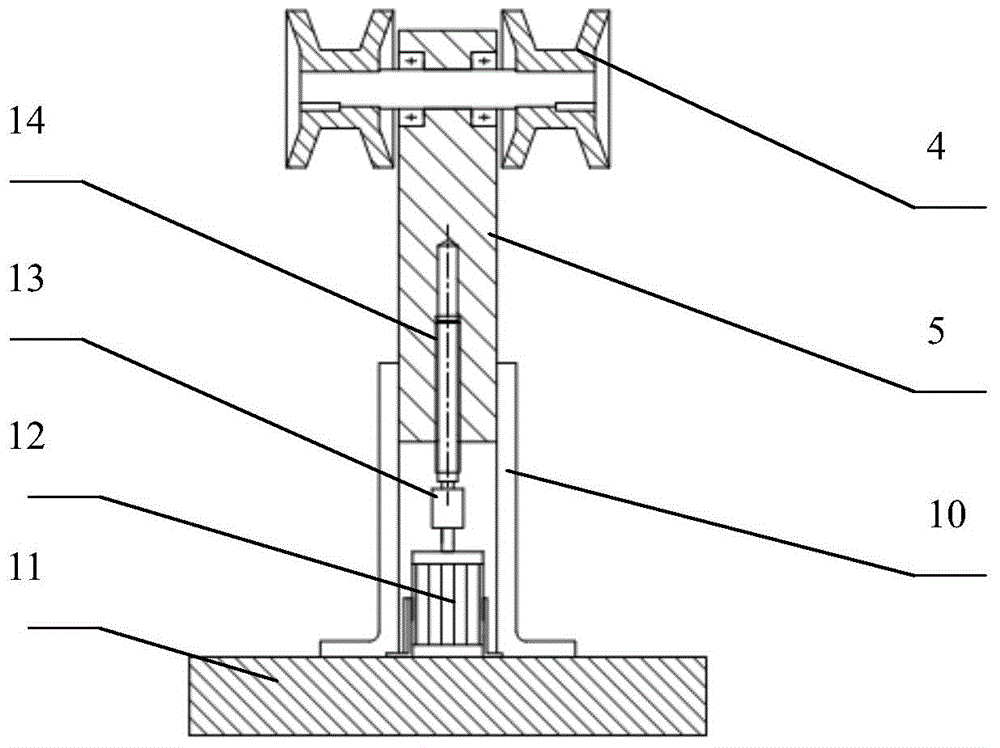

[0023] The pulley 4 is arranged on the top of the lifting device, and is used to clamp the transmission line 1 and can roll and walk on the transmission line 1. The pulley 4 is arranged on the telescopic column 5, and rises or falls with the telescopic column 5.

[0024] See imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com