Vertical continuous discharge sedimentation centrifuge

A settling centrifuge and centrifuge technology, applied to centrifuges, centrifuges with rotating drums, etc., can solve the problems of low moisture content, unsatisfactory speed difference, and poor speed, and achieve simple production and manufacturing , the control part is simple, and the speed difference ratio is constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The vertical continuous unloading sedimentation centrifuge of the present invention will be further described below in conjunction with the drawings and specific embodiments:

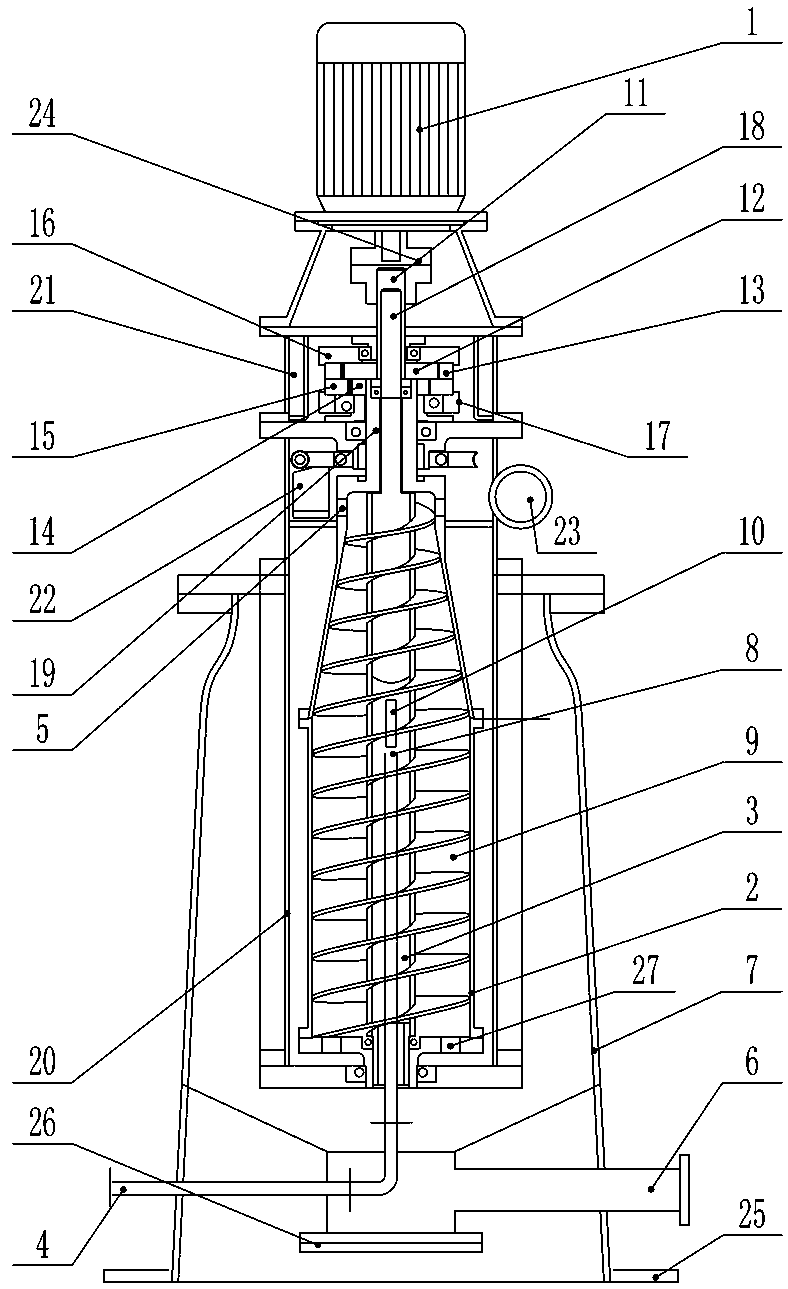

[0017] Such as figure 1 As shown, the vertical continuous discharge sedimentation centrifuge of the present invention includes a motor 1, a rotating drum 2, a screw pusher 3, a feed pipe 4, a slag outlet 5, a liquid outlet 6, an overflow port 27, and a base 7. And the centrifuge housing 20. The feed pipe 4 communicates with the distribution chamber 8 in the screw pusher 3, and the screw pusher 3 is provided with a discharge port 10 communicating with the drum cavity 9 of the rotating drum 2. The centrifuge housing 20 is vertically installed on the base 7, and the motor 1 is installed on the top of the centrifuge housing 20. The liquid outlet 6 and the inlet of the feed pipe 4 are both located below the centrifuge housing 20, the slag outlet 5 is arranged at the upper small end of the rotating drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com