Pop-up shelving system

A shelf and floor technology, applied in the field of shelf systems, can solve problems such as time-consuming, difficult assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

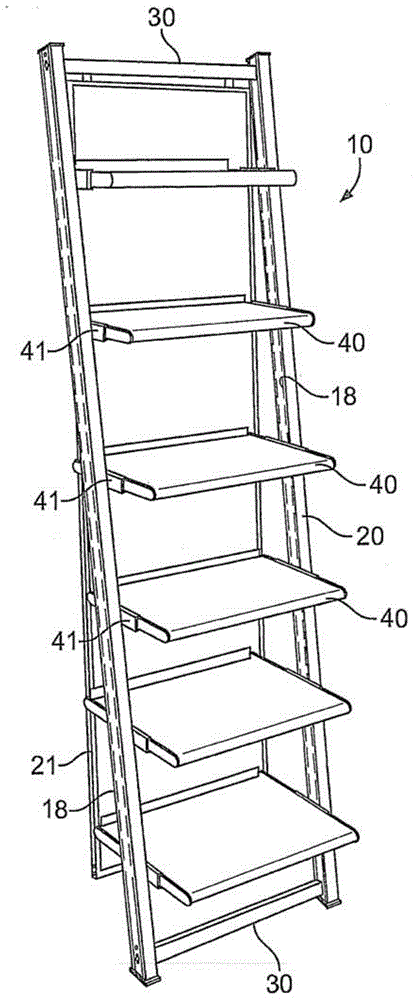

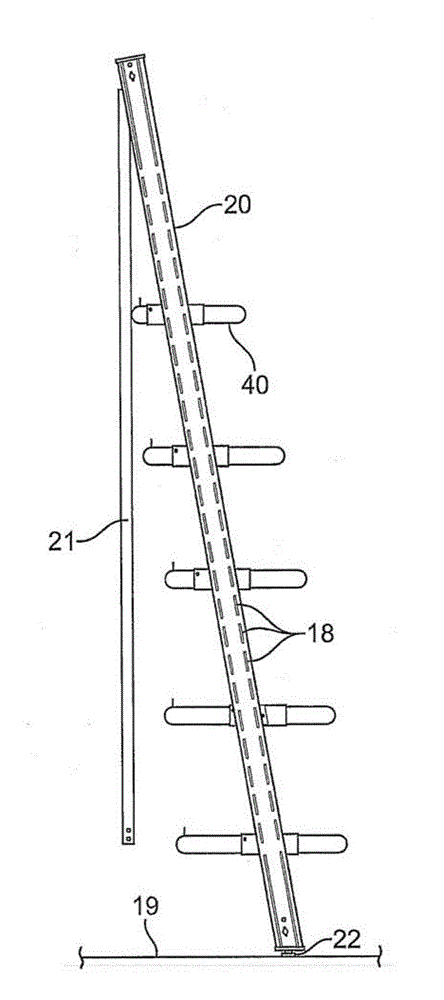

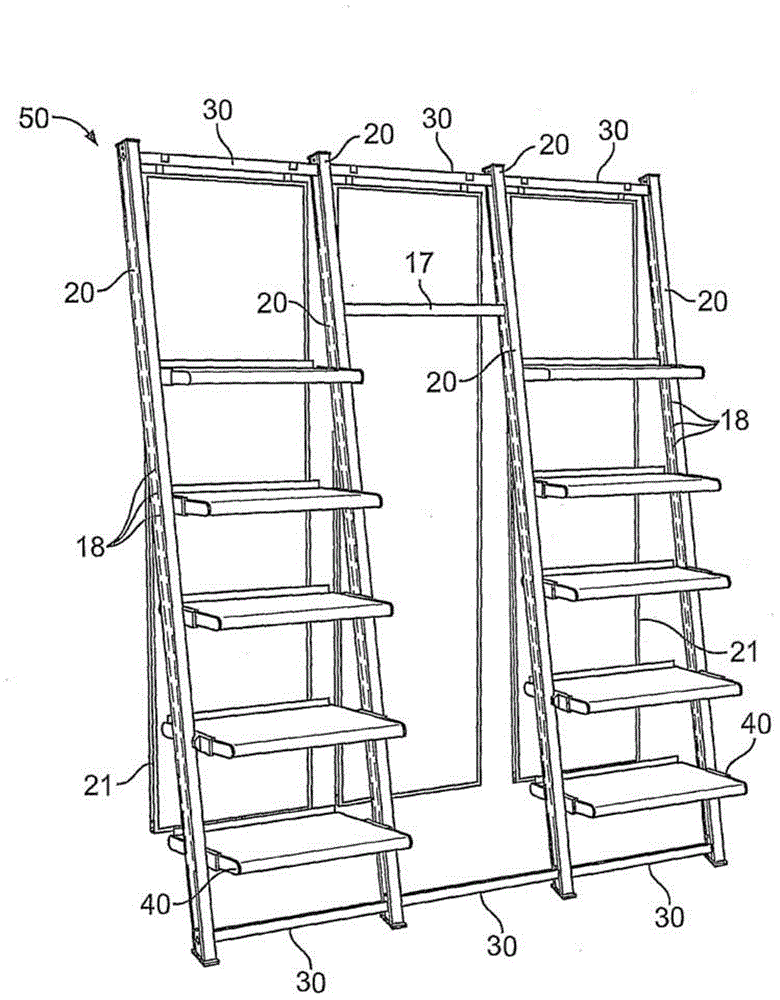

[0020] refer to figure 1 and figure 2 , shows a shelf assembly 10 with vertical support columns 20 . The supports 20 are secured together in spaced relation by tie rods 30 at upper and lower locations of the shelf assembly 10 . Shelves 40 or other accessories (such as booms 17 (see image 3 )) is secured between the vertical supports 20 by brackets 41 on both sides of the shelf. The back panel 21 may be a laminate and serves as a decorative backdrop for items displayed on the shelf. Thus, such a rear panel 21 may have a decorative design, as desired. figure 2 The rear panel 21 , best seen in , does not support the shelf assembly nor touch the floor 19 .

[0021] The vertical support column 20 leans against the wall at an angle of about 10°-20° and preferably 10°. Each vertical support may have non-slip feet 22 . image 3 A further embodiment is shown wherein the shelf assembly 50 is a multi-unit assembly having interconnected upright supports 20 with rods 30 between a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com