Overhead cultivation matched rice seedling transplanting robot and control method thereof

A technology of an elevated cultivation and control method is applied in the field of an elevated cultivation supporting seedling transplanting robot and its control field, which can solve the problem that the transplanting of seedlings to an elevated cultivation bed cannot be satisfied, and achieve the effect of meeting the needs of automatic transplanting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

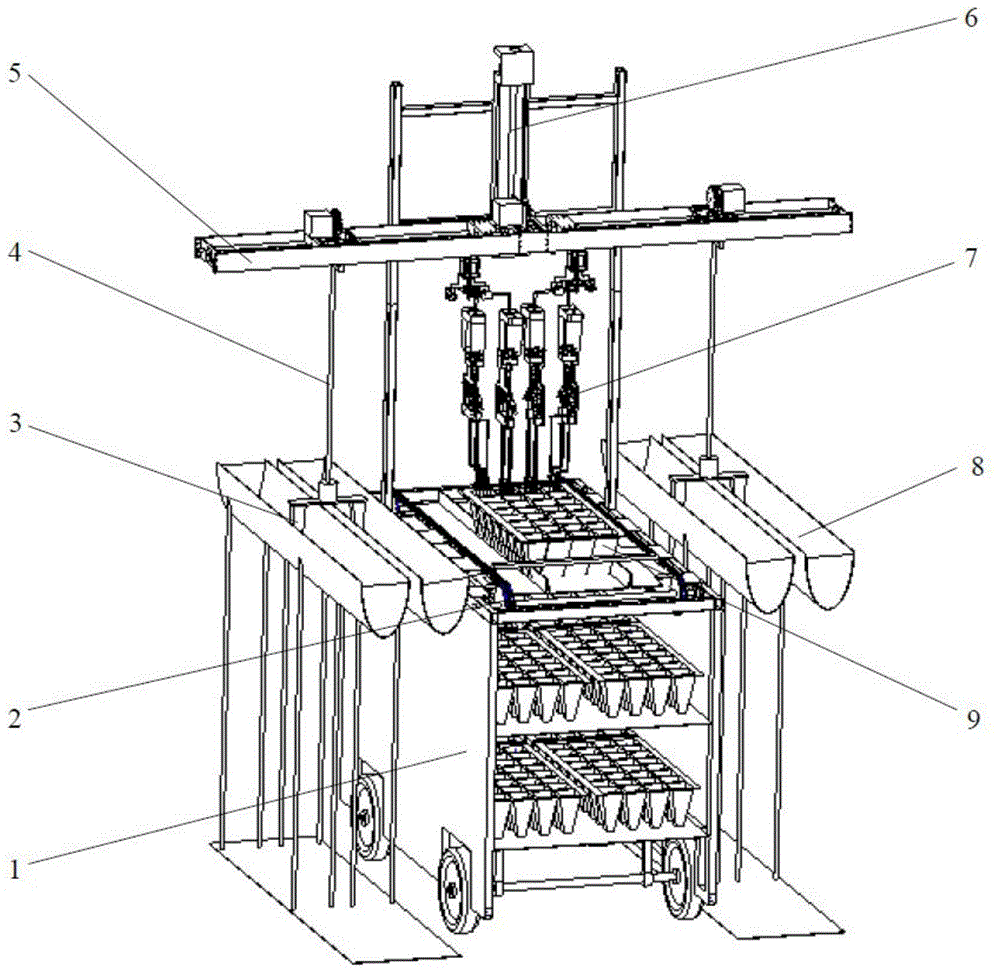

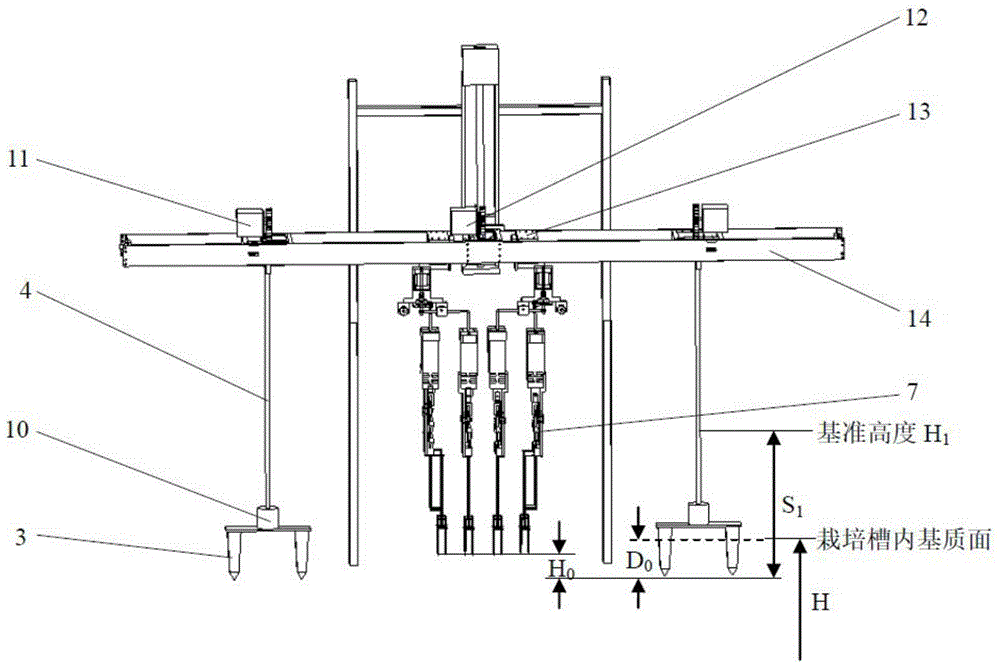

[0045] Such as figure 1 and figure 2 As shown, the elevated cultivation supporting rice seedling transplanting robot of the present invention is composed of a mobile trolley 1, a tray intermittent feeding unit 2, a vertical movement unit 6, a horizontal symmetrical movement unit 5, an end effector 7, and a punching unit. Wherein the frame of the vertical movement unit 6 is fixed on the car body of the mobile trolley 1, and the moving part of the vertical movement unit 6 is fixed with the frame 14 of the horizontal symmetrical movement unit 5. The frame of the tray intermittent feeding unit 2 is fixed on the car body of the mobile trolley 1, and the tray 9 to be transplanted is horizontally placed on the moving surface of the tray intermittent feeding unit 2.

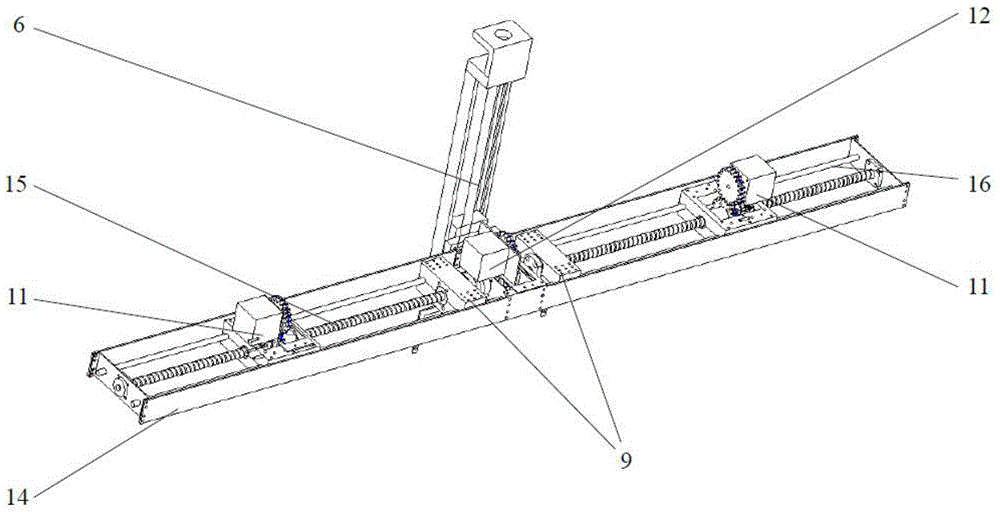

[0046] Such as image 3 Yes, the horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com