Harvester header capable of realizing line spacing adjustment

A row spacing adjustment and harvester technology, which is applied in the direction of headers, harvesters, agricultural machinery and implements, etc., can solve the problems of low harvesting efficiency and few rows harvested at the same time, and achieve high harvesting efficiency, simple operation and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

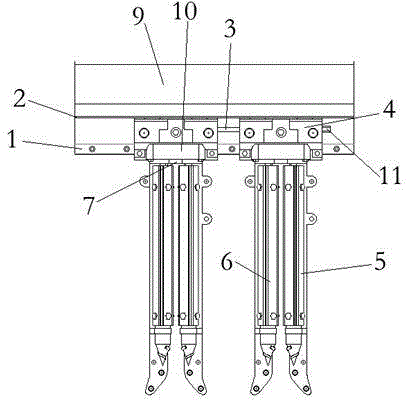

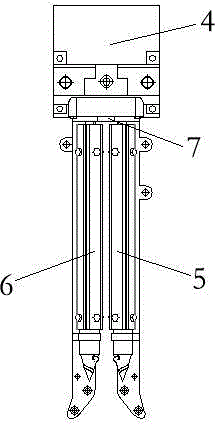

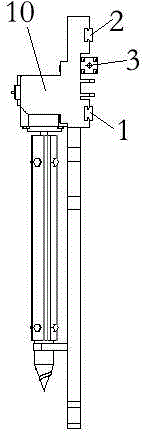

[0016] A harvester header capable of row spacing adjustment, comprising a conveyor bucket provided with a parallel I-shaped guide rail 1 and a parallel I-shaped guide rail 2 2, the two I-shaped guide rails are provided with an ear picking roller group mechanism 10. Sensor mechanism and hydraulic transmission mechanism. It is characterized in that the ear picking roller group mechanism 10 includes: a gear box 4, which is fitted on the I-shaped guide rail and can slide left and right along the guide rail; ear picking roller one 6, which is an ear picking roller that can rotate clockwise , and gear box 4 links to each other; Ear picking roller two 5, it is the ear picking roller that can turn counterclockwise, links to each other with gear box 4; Described hydraulic mechanism includes: hydraulic motor 8 and hydraulic cylinder 3.

[0017] Further, the hydraulic motor 8, which is to provide the power source for the rotation of the ear-picking roller one 6 and the ear-picking roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com