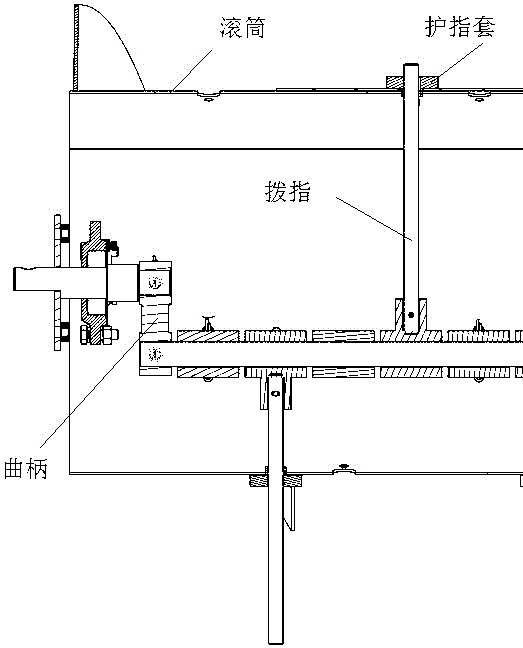

Telescopic shifting finger protecting cover structure for spiral pushing and conveying device and mounting mode

A technology of auger and installation method, which is applied in application, threshing equipment, packaging, etc., and can solve problems such as vibration and energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

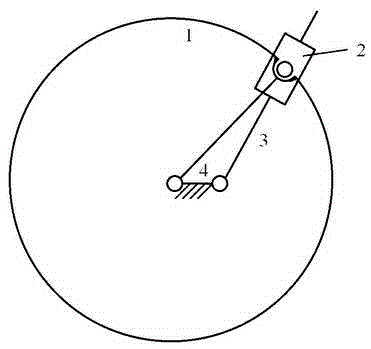

[0018] image 3 It is a schematic diagram of the mechanism movement of the new telescopic finger movement mechanism. No. 1 is the conveying roller, which rotates clockwise and is the active part of the mechanism. No. 2 is the newly added turning block, which can perform rotational movement relative to 1. No. 3 is the telescopic dial Refers to the reciprocating movement relative to the rotary block 2, which is shown as extending and retracting to the drum, and at the same time rotates clockwise with the drum 1 to realize the feeding action, which is the functional executive part of this mechanism. Number 4 is a frame, which is relatively stationary and is used to install the rotary joint of the drum and the finger.

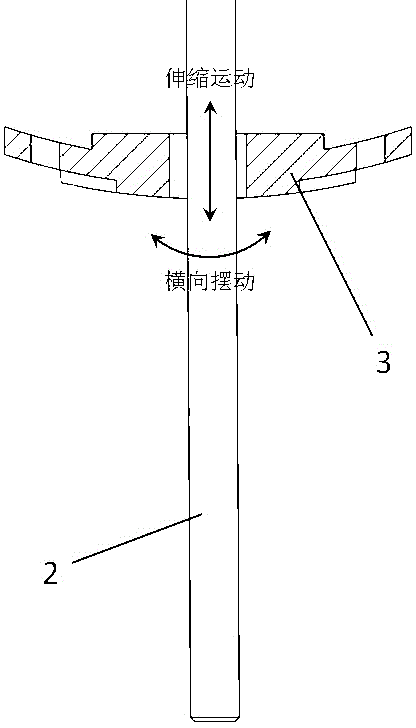

[0019] Figure 4 In the schematic diagram of the installation structure of the rotary block, the rotation between the rotary block and the telescopic fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com