Automatic mechanism for rapid switching of following positioning tooling

A technology of fast switching and positioning tooling, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problem that the conveying trolley cannot be used for multiple purposes, and achieve the effect of reducing positioning correction procedures, fast switching speed, and occupying less rhythm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

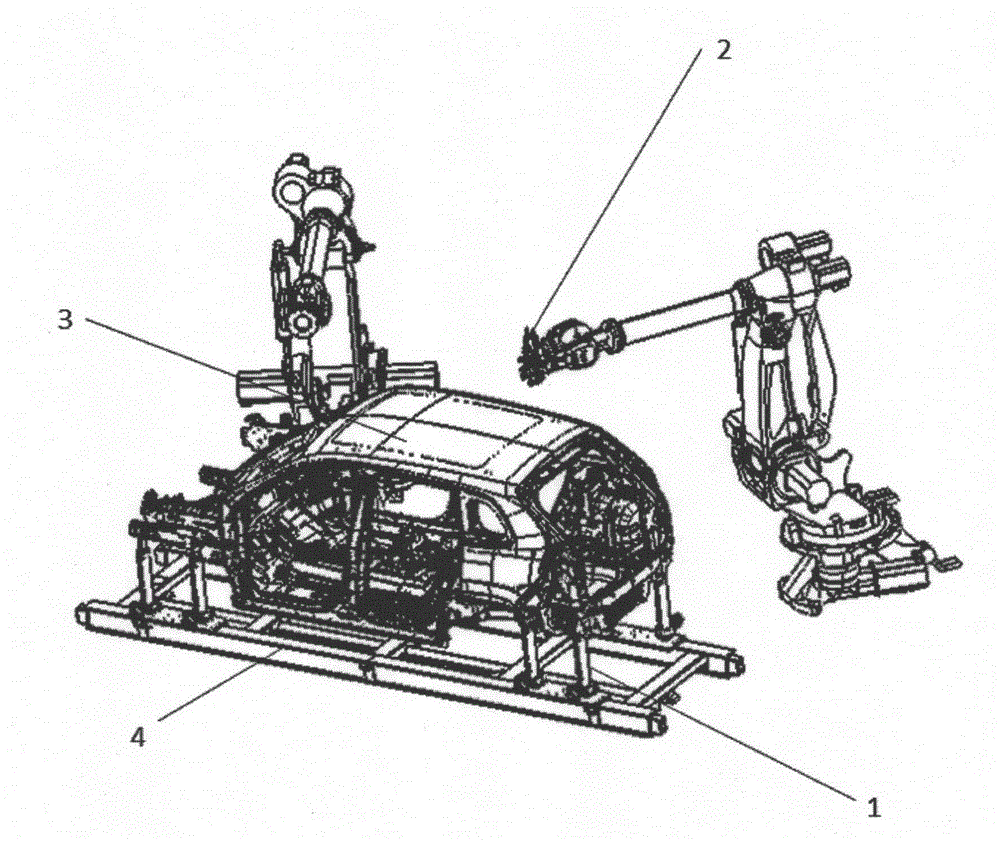

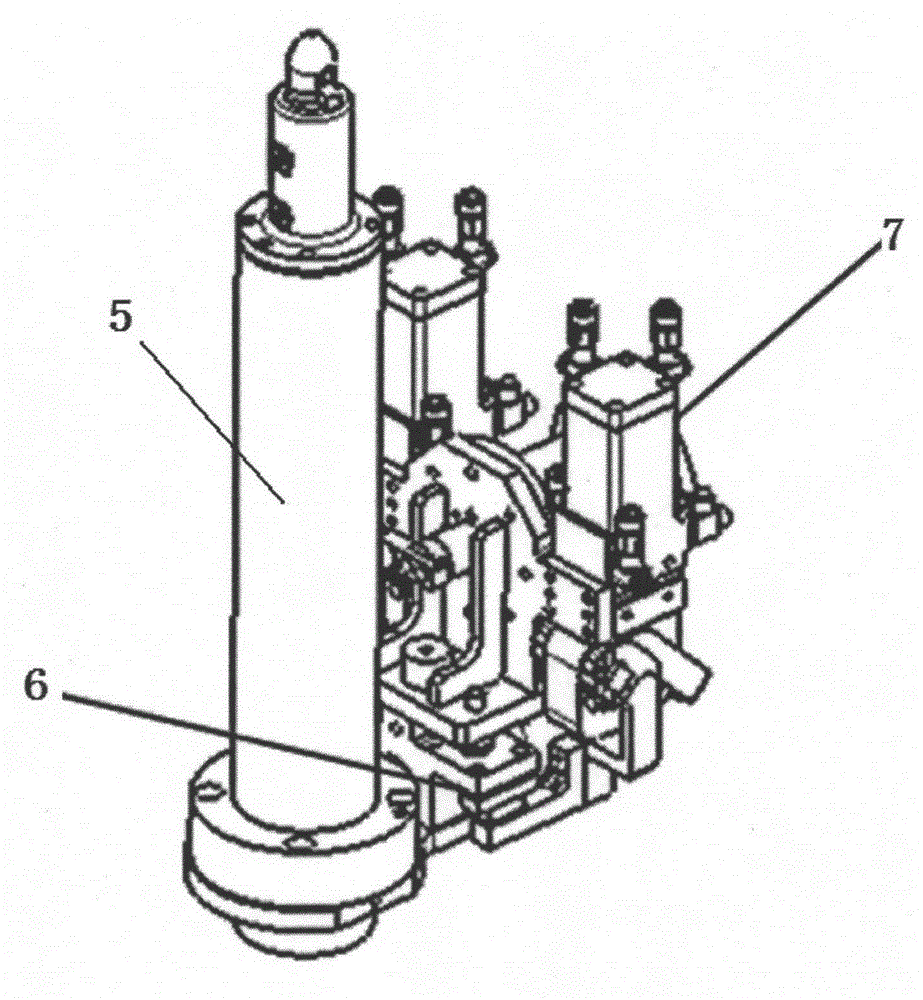

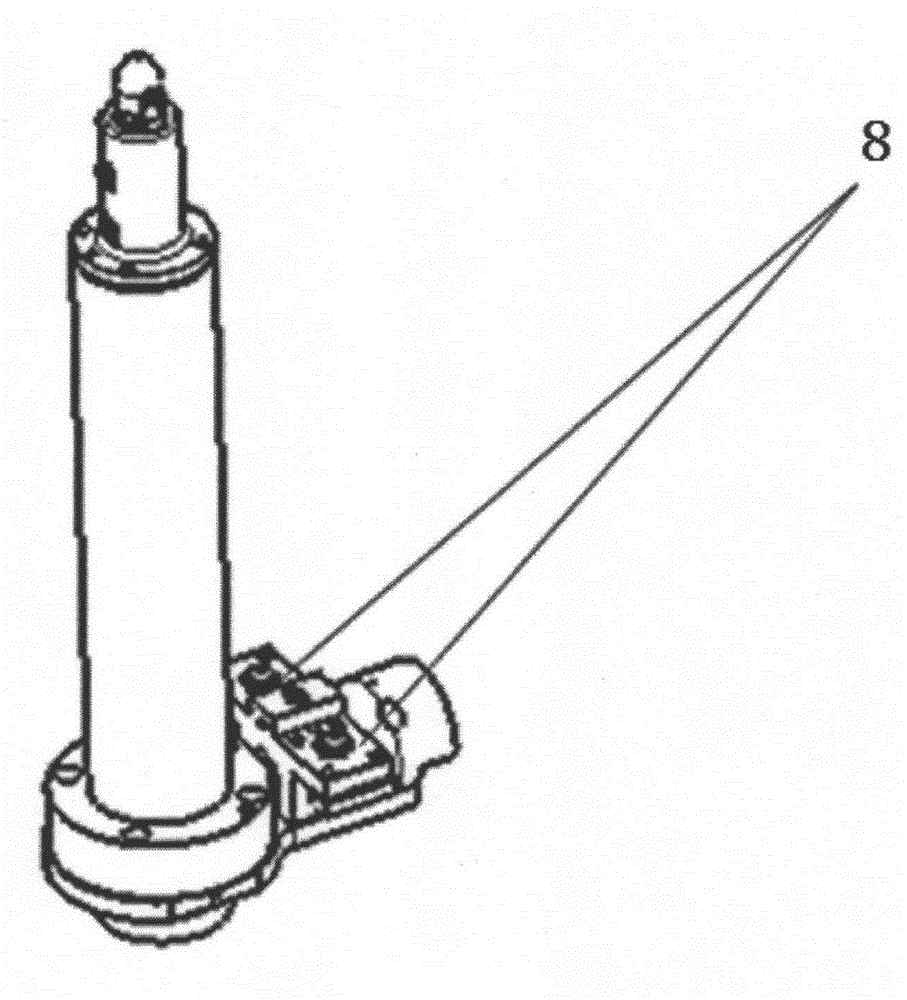

[0019] The invention provides an automatic mechanism for fast switching of accompanying positioning tooling, combined with figure 2 , including replaceable column 5. Usually, a robot is used to grasp the column 5 and move the column 5 close to the position that needs to be positioned on the pallet trolley 4 . Pre-fix and lock the female head at the position to be positioned. Since the robot cannot meet the precise positioning when it is grasped and placed, rely on the guide groove on the female head to guide the male head to be accurately positioned and then locked.

[0020] In order to allow the column 5 on the pallet trolley 4 to be quickly replaced with the assistance of the industrial robot arm, as figure 2 As shown, the present invention adds a positioning and guiding mechanism 6 on the side of the column 5 to cooperate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com