Automatic loading-unloading device of machine tool

An automatic loading and unloading and machine tool technology, applied in the mechanical field, can solve problems such as inaccurate workpiece positioning, workpiece clamping deviation, and limited adjustment angle, so as to achieve accurate and stable gripping of workpieces by air grippers, stable gripping of workpieces by air grippers, Effects that are not easy to shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

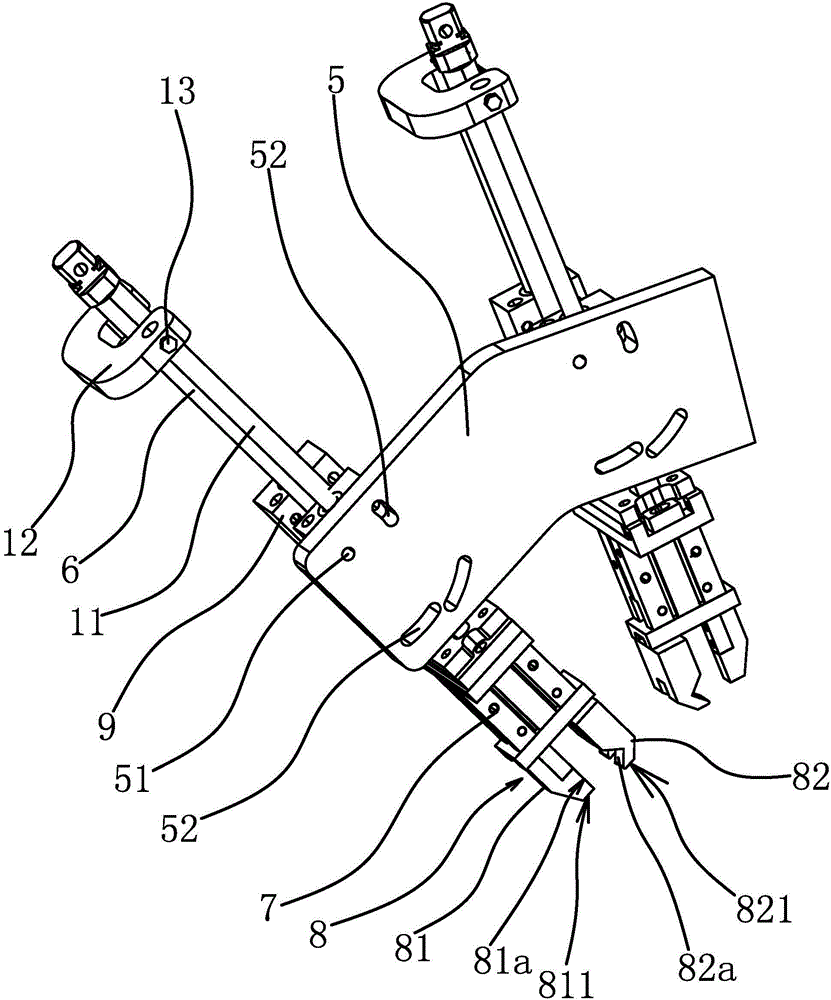

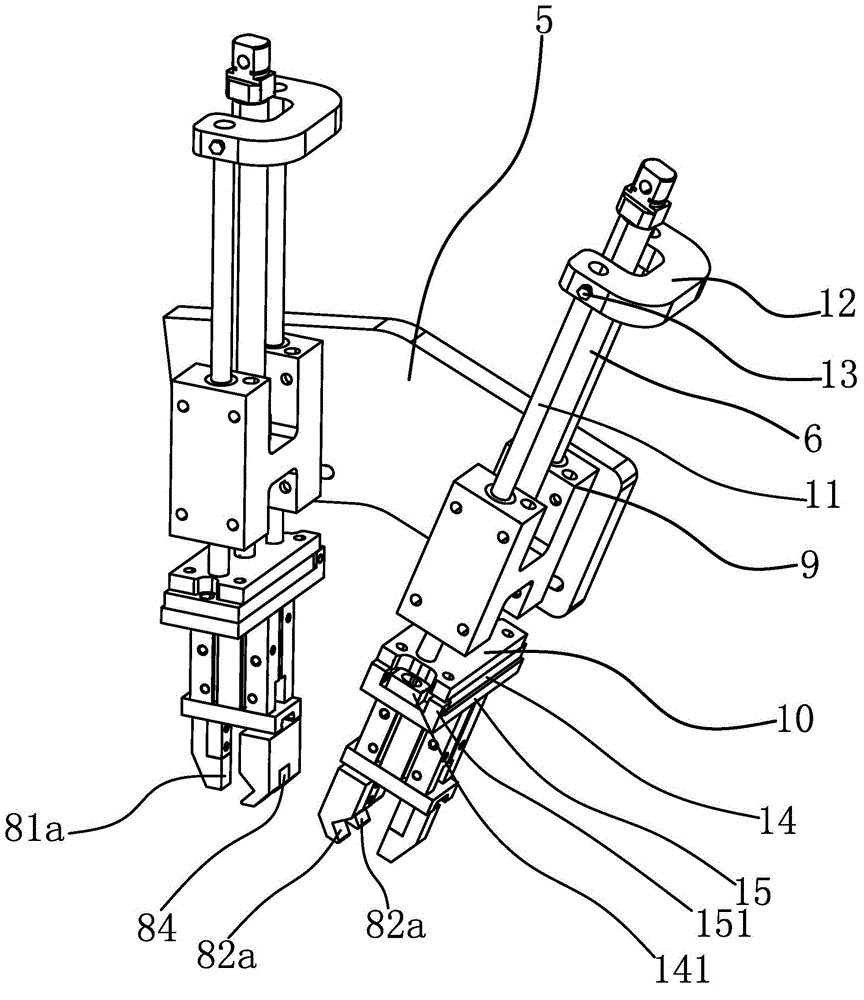

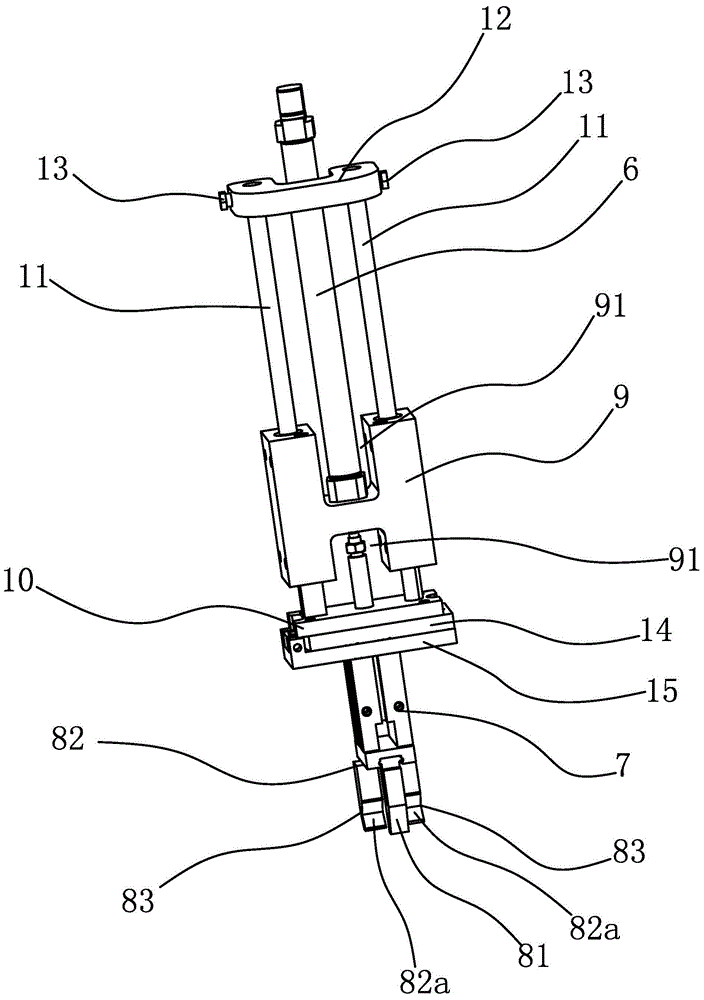

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0025] The automatic loading and unloading device of this machine tool includes installation column 1, servo motor 2, linear module 3, slider 4, connecting plate 5, hinged round hole 51, arc-shaped hole 52, telescopic cylinder 6, air claw cylinder 7, air claw 8. Claw head 1 81, clamping surface 1 81a, bottom surface 1 811, claw head 2 82, clamping surface 2 82a, bottom surface 2 821, claw toe 83, interval 84, mounting block 9, cavity 91, partition 92. Fixed plate 10, guide rod 11, limit plate 12, adjustment screw 13, angle adjustment plate 14, adjustment part 141, mounting plate 15, block 151.

[0026] Specifically, as figure 1 and Figure 4As shown, the automatic loading and unloading device includes an installation col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com