Oil press

An oil press and drive shaft technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of low oil yield, insufficient heating material, and poor extrusion material effect, so as to improve the oil yield and ensure Oil-pressing effect and balanced extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

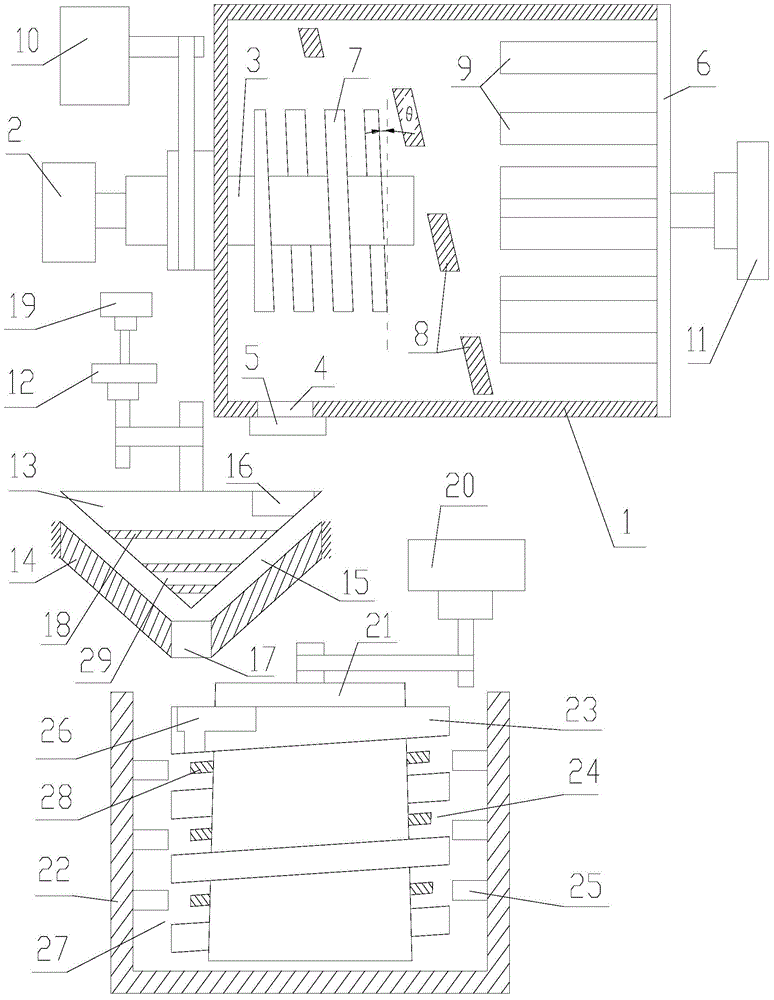

[0040] refer to figure 1 , 2 ;

[0041] An oil press provided by the present invention includes a frying part and an oil pressing part;

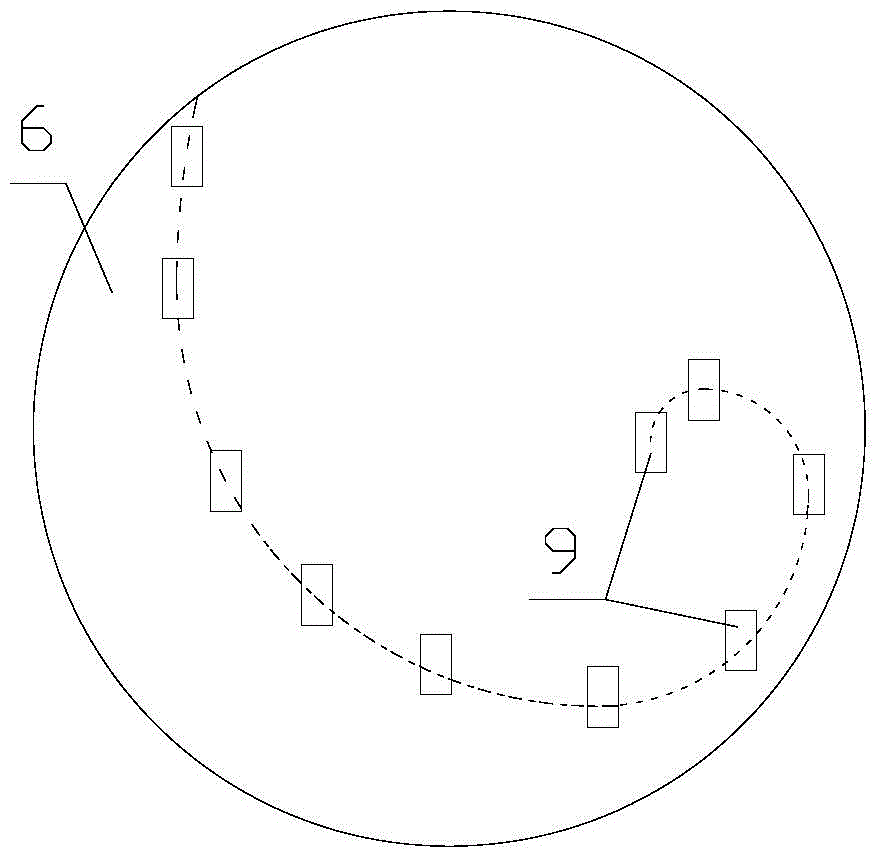

[0042] The frying section includes a frying box 1, a first motor 2, and a drive shaft 3. The frying box 1 is provided with a material port 4 for adding materials and discharging materials. The material port 4 is provided with a cover 5. The frying box One side of 1 is provided with a cover plate 6:

[0043] The first motor 2 is in drive connection with the transmission shaft 3, one end of the transmission shaft 3 is placed in the frying box 1, and the end of the transmission shaft 3 located in the frying box 1 is provided with a helical main stirring blade along the axial direction of the transmission shaft 3 7. The angle between the lower surface of the main stirring blade 7 and the plane perpendicular to the axial direction of the transmission shaft is θ, 5°≤θ≤10°, and the length of the main stirring blade 7 along the radial direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com