A high-speed railway catenary anti-positioning elastic damper support mechanism

An elastic damper, high-speed railway technology, applied in the direction of power lines, transportation and packaging, vehicle components, etc., can solve the problems of train speed sensor failure, poor contact of wires, and reduced operating speed, so as to reduce wind damage loss and overall The structure is compact and reasonable, and the effect of improving wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

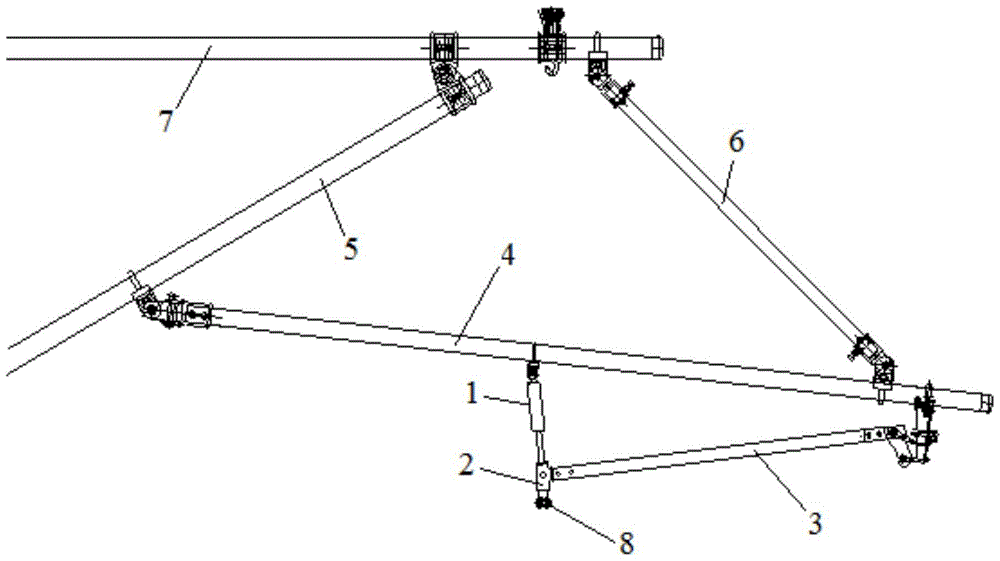

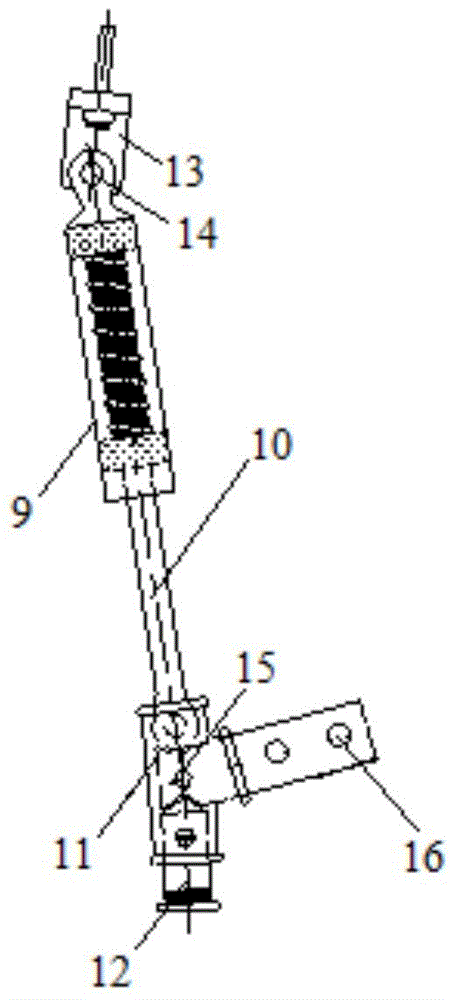

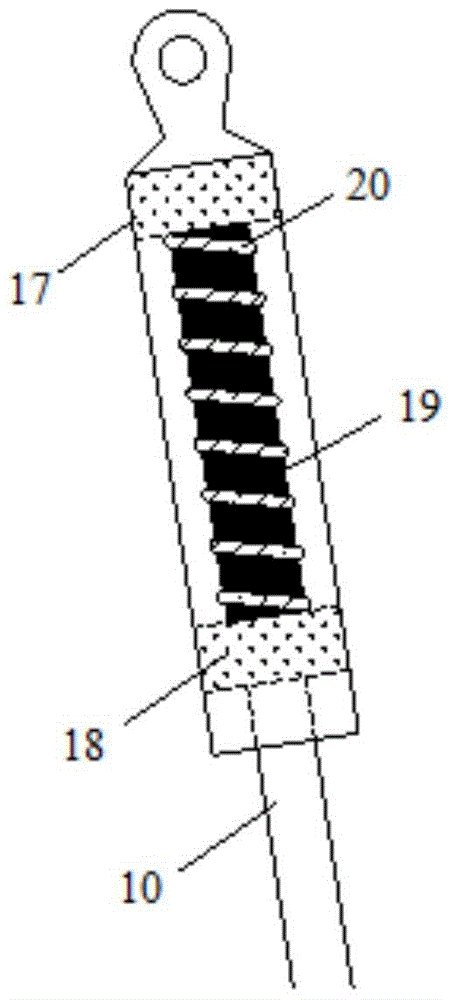

[0033] Such as figure 1 As shown, a high-speed railway catenary anti-positioning elastic damper support mechanism, the support mechanism is used to support and fix the arm structure in the high-speed railway catenary system, the arm structure includes a flat arm 7, an inclined arm 5, The positioning tube 4, the positioner 3 and the positioning tube support 6, the inclined arm 5 and the positioning tube support 6 are respectively hinged with the flat arm 7, one end of the positioning tube 4 is hinged with the inclined arm 5, and the other end is hinged with the positioning tube support 6, One end of the locator 3 is hinged to the connecting frame of the positioning tube 4, and the other end is fixedly connected to the supporting mechanism. The supporting mechanism includes a damping generating unit 1 and a positioning pin unit 2. One end of the damping generating unit 1 is fixedly connected to the positioning tube 4, and the other end is fixed by positioning The pin unit 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com