Rocker overturning testing method for jacket launching barge

A technology of overturning test and jacket, which is applied in the direction of barge/flat-bottomed boat, etc. It can solve the problems of a lot of preparation and finishing work, difficult manual work, and long test cycle, so as to reduce the mooring test cycle and reduce the The effect of test tooling preparation and finishing work, shortening test cycle

Active Publication Date: 2015-09-09

CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the field of shipbuilding, after the production and installation of the rocker arm is completed, a series of overturning tests are required, and during the test, check the contact between the rocker arm leveling gasket and the deck reinforcement doubler plate, check the rotating shaft, the semi-circular sleeve and the lock Check the hinge condition, check the contact between

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

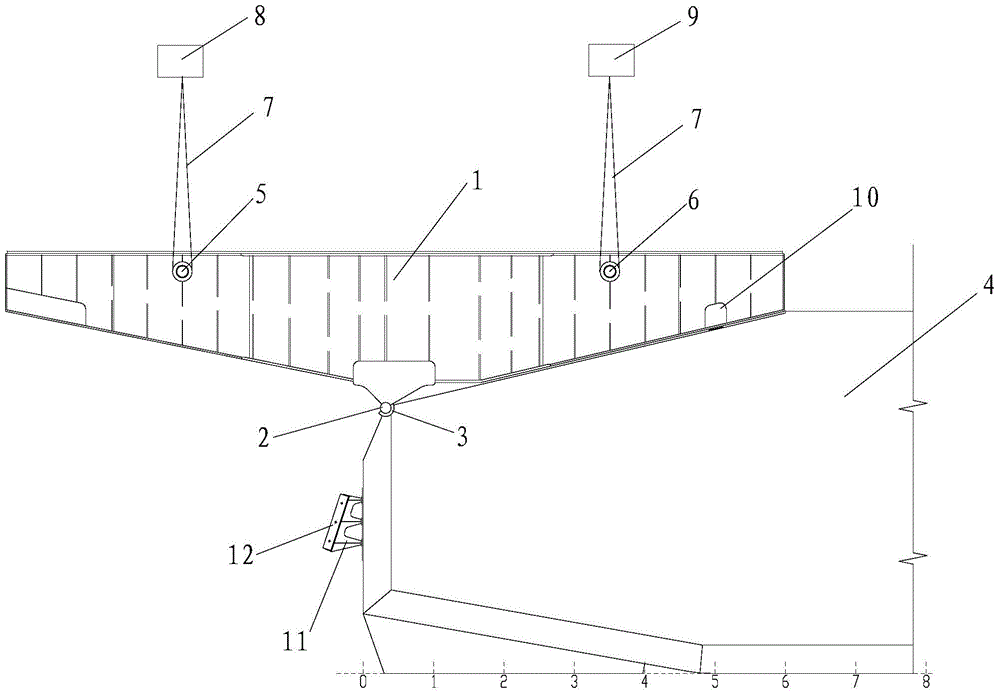

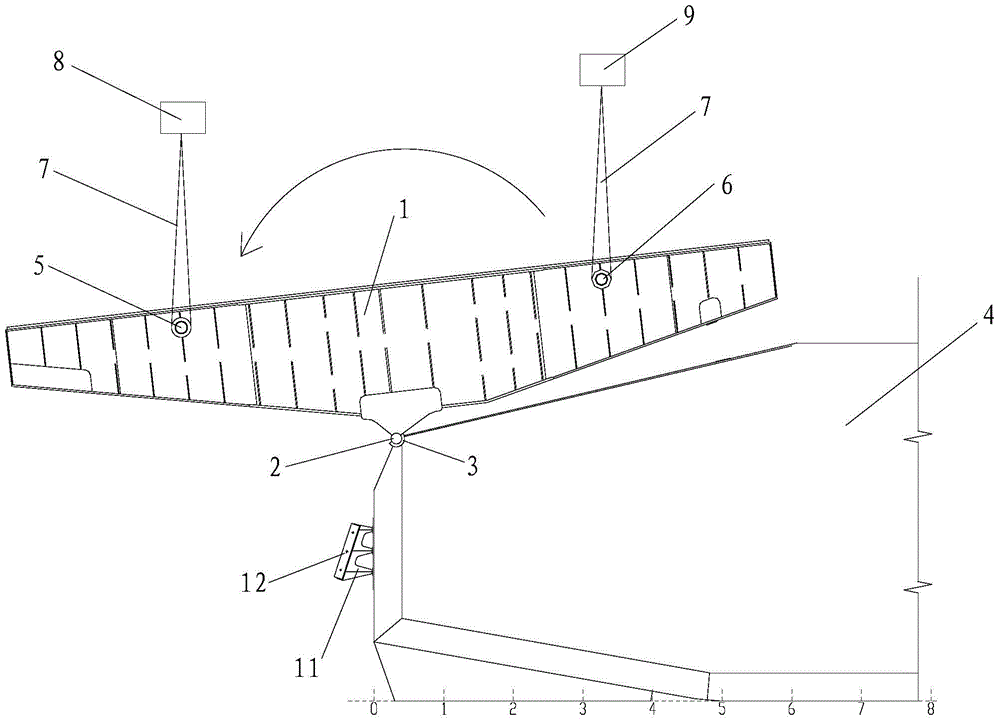

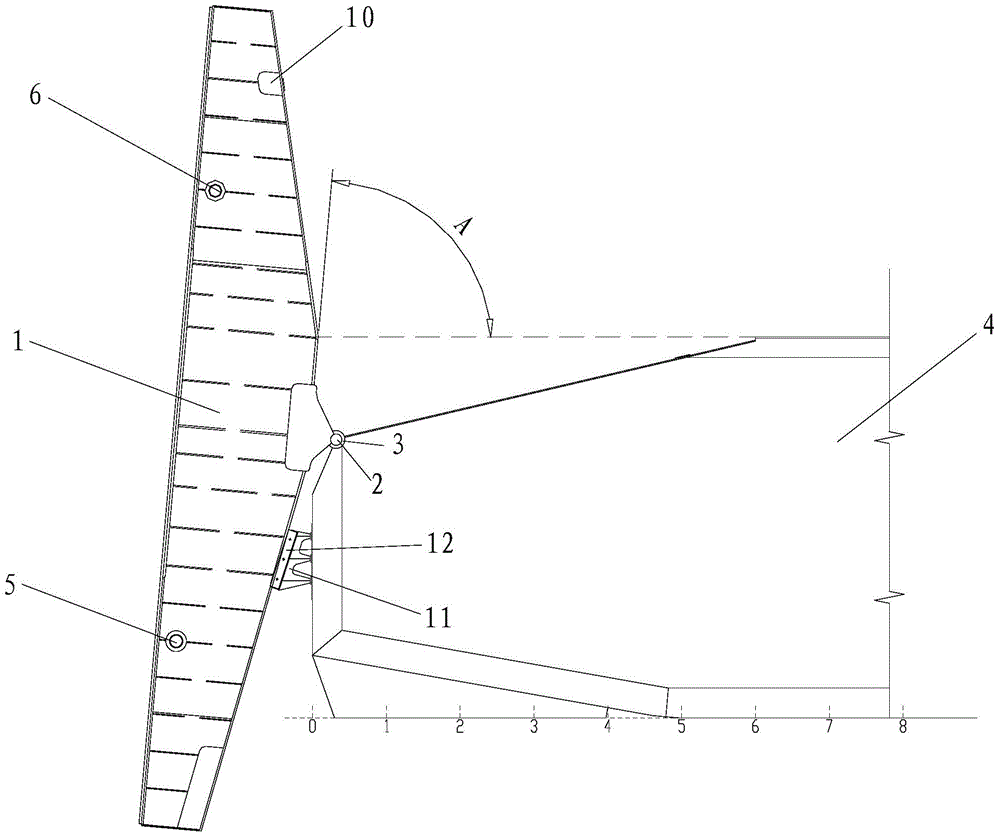

The invention relates to the technical field of marine installation testing, in particular to a rocker overturning testing method for a jacket launching barge. In the testing process, the rocker overturning lifting force is provided through a crane in a dock, and the adjustable and controllable crane lifting force is capable of guaranteeing the precise and safe regulation and control in the rocker overturning process and convenient for controlling the rocker to statically locate at a position to be tested to test. The rocker overturning testing method for the jacket launching barge does not need counterweight iron and the like testing fixture, the testing fixture preparation before testing and the tail-in work after testing are greatly reduced, the testing period is shortened, the efficiency is improved, the testing process can be performed in the dock, the mooring testing period of the launching barge at the wharf is shortened, and the wharf resource and testing cost can be saved.

Description

technical field [0001] The invention relates to the technical field of ship device testing, in particular to a rocker turning test method for a jacket launching barge. Background technique [0002] The rocker arm of the launching barge is a key system on the launching barge. It is the main load-bearing system and force-bearing system of the jacket and other equipment during the launching process. , when the jacket slides along the launching barge track to the stern of the launching barge, the rocker arm will drag the jacket up and turn over together under the double action of the jacket pressure and the stern inclination of the launching barge to push the jacket into the water, and finally the jacket leaves the barge, The rocker arm stands at the stern of the launching barge. In the field of shipbuilding, after the production and installation of the rocker arm is completed, a series of overturning tests are required, and during the test, check the contact between the rocker...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B63B35/28

Inventor 冯仕清陈标烘练博强高永安

Owner CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap