Eutectic Structure Thermal Barrier Coating Material and Its Powder Manufacturing Method Used for Thermal Spraying

A thermal barrier coating and coating material technology, applied in the field of high temperature resistant ceramic materials, can solve the problems of micropore sintering shrinkage, phase change, grain growth, etc., achieve good high temperature phase and chemical composition stability, overcome the Effect of grain growth and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: preparation chemical composition is (La 0.5 Yb 0.5 ) 2 Zr 2 o 7 Thermal Barrier Coating Materials:

[0033] a The lanthanum oxide, ytterbium oxide and zirconium oxide with a purity greater than 99wt.% are classified according to their chemical composition (La 0.5 Yb 0.5 ) 2 Zr 2 o 7 The molar ratio was mixed, and a certain amount of absolute ethanol was added for ball milling for 4 hours, and then dried.

[0034] b After 20MPa dry pressing and 200MPa cold isostatic pressing, the blank is made.

[0035] c Place the crucible with the blank in the electric furnace, raise the temperature to 1600°C, and perform a high-temperature reaction at 1600°C in an air atmosphere for 10 hours, and then cool with the furnace.

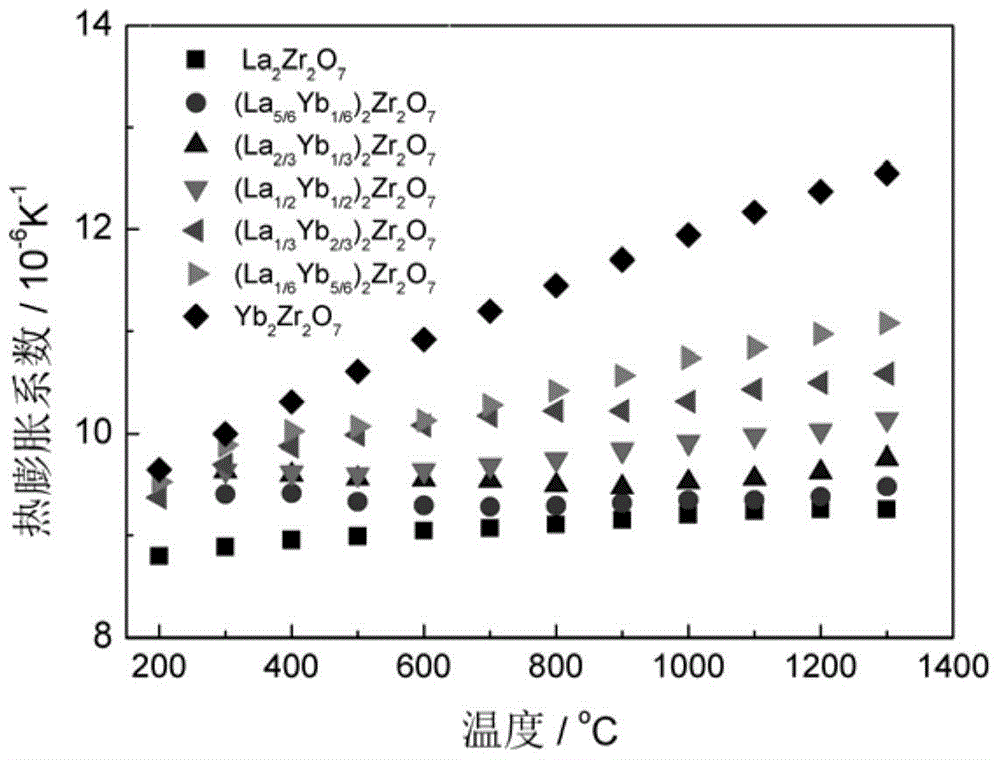

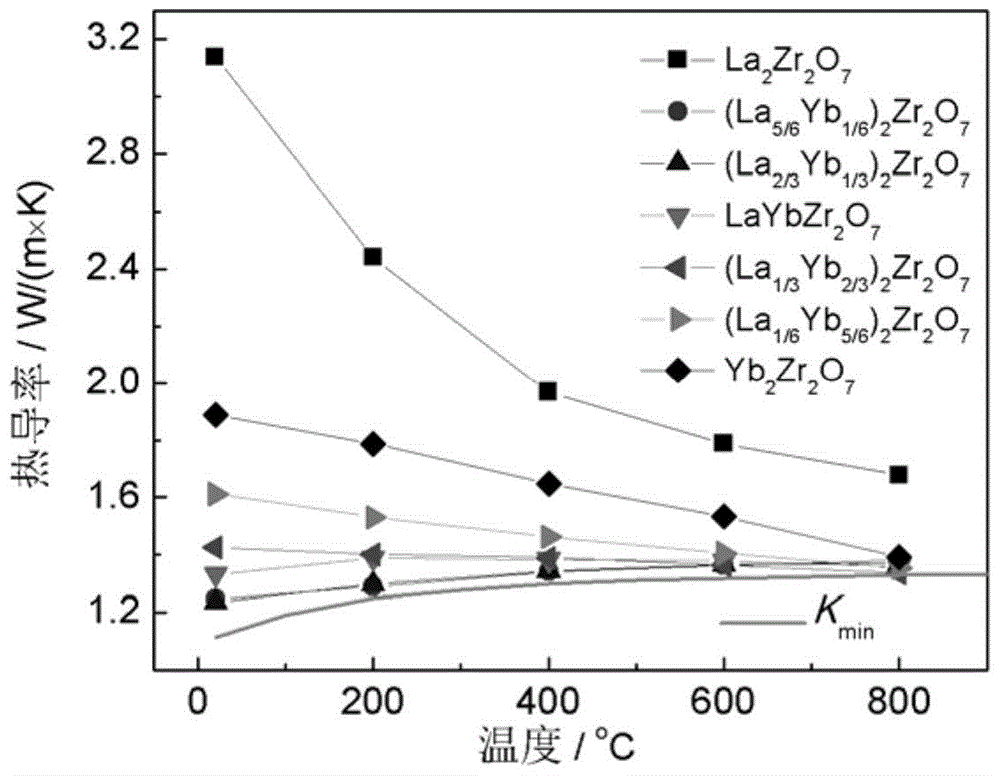

[0036] d obtains the chemical composition as (La 0.5 Yb 0.5 ) 2 Zr 2 o 7 Material, the thermal conductivity of the sample is 1.3W / m·K~1.5W / m·K, and the coefficient of thermal expansion is 11.0×10 -6 / K~11.5×10 -6 / K (700℃~1300℃), th...

Embodiment 2

[0038] Embodiment 2: preparation chemical composition is (Ce 0.5 Yb 0.5 ) 2 Zr 2 o 7 Thermal Barrier Coating Materials:

[0039] a the mass percentage is 99wt% lanthanum oxide, ytterbium oxide and zirconium oxide with chemical composition (Ce 0.6 Yb 0.4 ) 2 Zr 2 o 7 The molar ratio was mixed, and a certain amount of absolute alcohol was added for ball milling for 4 hours, and then dried.

[0040] b After 20MPa dry pressing and 200MPa cold isostatic pressing, the blank is made.

[0041] c Place the zirconia crucible with the blank in the electric furnace, raise the temperature to 1650°C, and perform a high-temperature reaction at 1650°C in an air atmosphere for 8 hours, and then cool with the furnace.

[0042] d obtains the chemical composition as (Ce 0.5 Yb 0.5 )2 Zr 2 o 7 Material, the thermal conductivity of the sample is 0.9W / m·K~1.4W / m·K, and the coefficient of thermal expansion is 10.9×10 -6 / K~11.5×10 -6 / K (700℃~1300℃), the elastic modulus is 222~235GPa....

Embodiment 3

[0044] Embodiment 3: preparation chemical composition is (Pr 0.4 Y 0.6 ) 2 Zr 2 o 7 Thermal Barrier Coating Materials:

[0045] a The mass percent is 99wt% praseodymia, yttrium oxide and zirconium oxide with chemical composition (Pr 0.4 Y 0.6 ) 2 Zr 2 o 7 The molar ratio is mixed, and a certain amount of absolute alcohol is added to ball mill for 6 hours, and dried.

[0046] b After 20MPa dry pressing and 200MPa cold isostatic pressing, the blank is made.

[0047] c Place the zirconia crucible with the blank in the electric furnace, raise the temperature to 1550°C, and perform a high-temperature reaction at 1550°C in an air atmosphere for 14 hours, and then cool with the furnace.

[0048] d obtains the chemical composition as (Pr 0.4 Y 0.6 ) 2 Zr 2 o 7 Material, the thermal conductivity of the sample is 1.6W / m·K~1.9W / m·K, and the coefficient of thermal expansion is 9.9×10 -6 / K~10.5×10 -6 / K (700℃~1300℃), the elastic modulus is 222~235GPa. .

[0049] e The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com