High-efficiency electrolysis device

An electrolysis device and high-efficiency technology, applied in the direction of electrolysis process, electrolysis components, electrode shape/type, etc., can solve the problems of inconvenient cleaning and replacement of internal devices, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

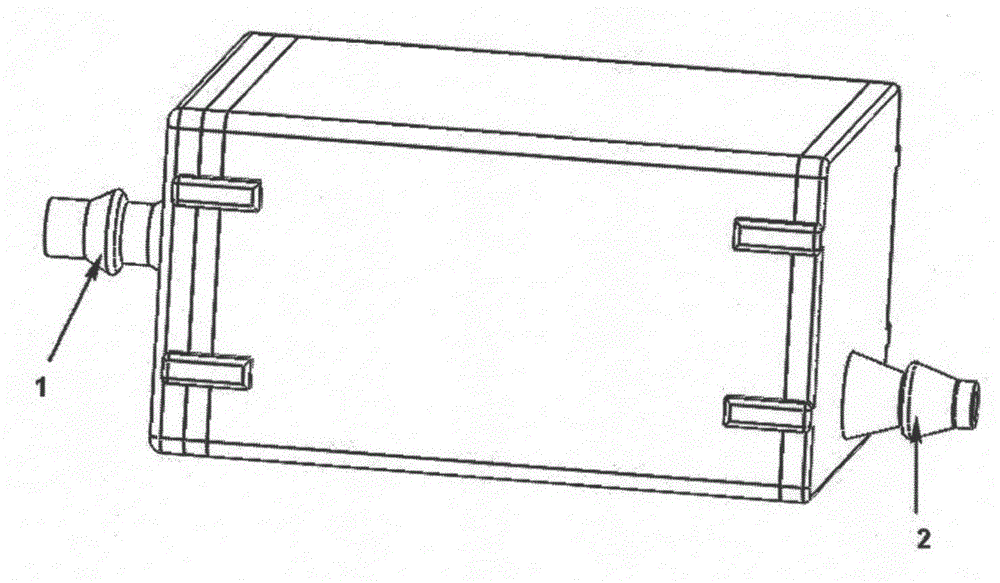

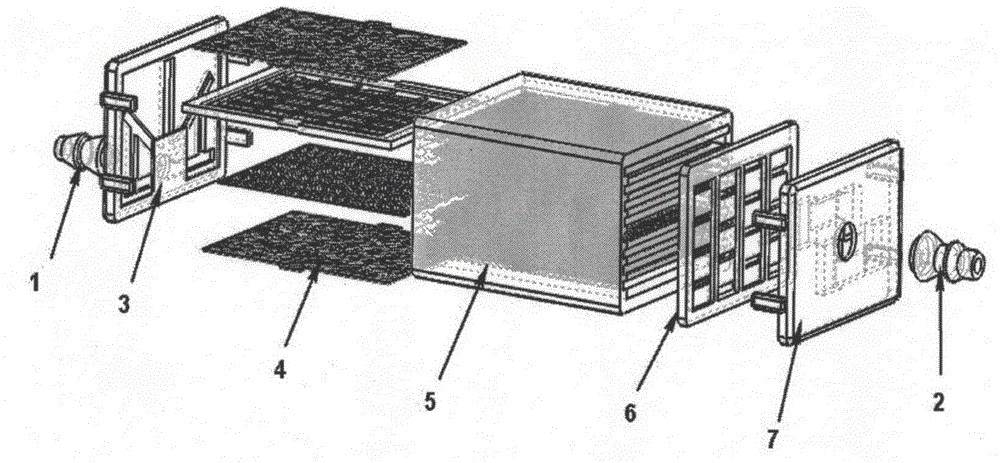

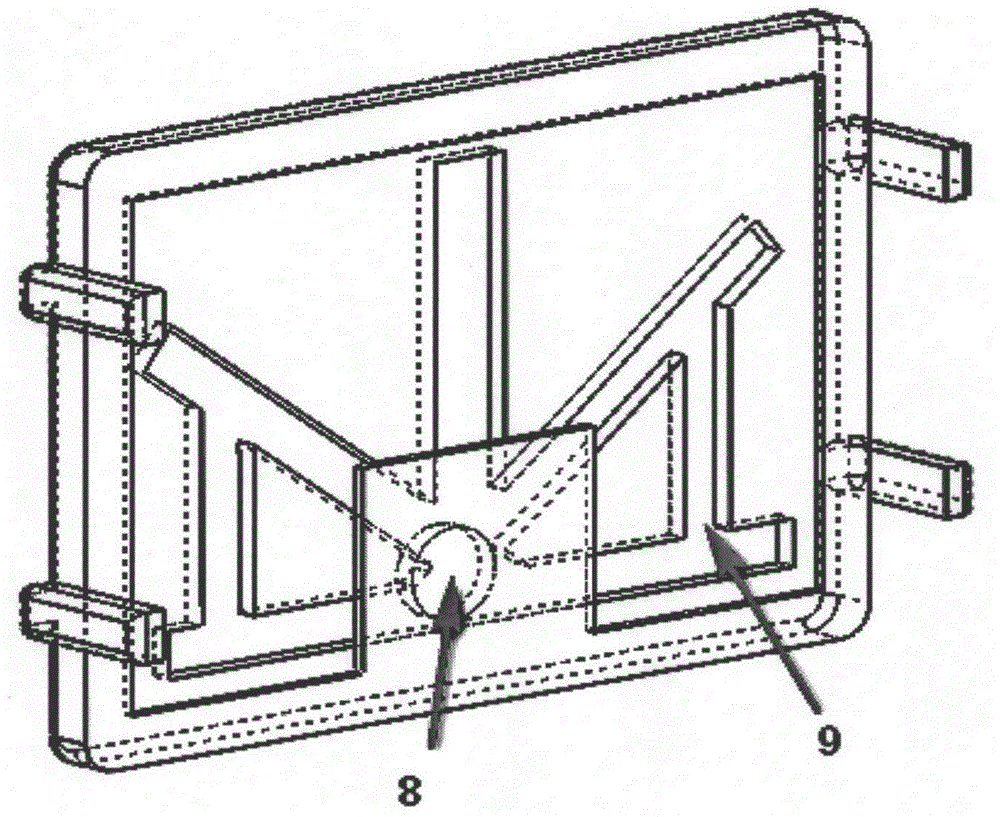

[0023] Such as figure 1 and figure 2 As shown, a high-efficiency electrolysis device provided by the present invention includes a housing 5, and an accommodation space is formed in the housing 5, and a plurality of electrode modules 4 are arranged in parallel in the accommodation space of the housing 5 from top to bottom. . combine Figure 7 , On the inner walls of both sides of the housing 5 there are slots 16 for snapping in the electrode modules, and the electrode modules are installed in the housing through the slots 16 . combine Figure 4 , 5 , 6 and 11, the electrode module 4 includes an electrode seat 13, the middle part of the electrode seat 13 is a mesh structure, and a power access groove 11 is opened at the edge of the electrode seat 13, a mesh positive electrode plate 12 and a mesh negative electrode plate 14 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com