Wheels for rail vehicles

A technology of rail vehicles and wheel discs, which is applied to wheels, wheels, and vehicle parts characterized by rail running parts, which can solve problems such as programming costs and complex structures, and achieve high-strength, simple calculations, and efficient design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

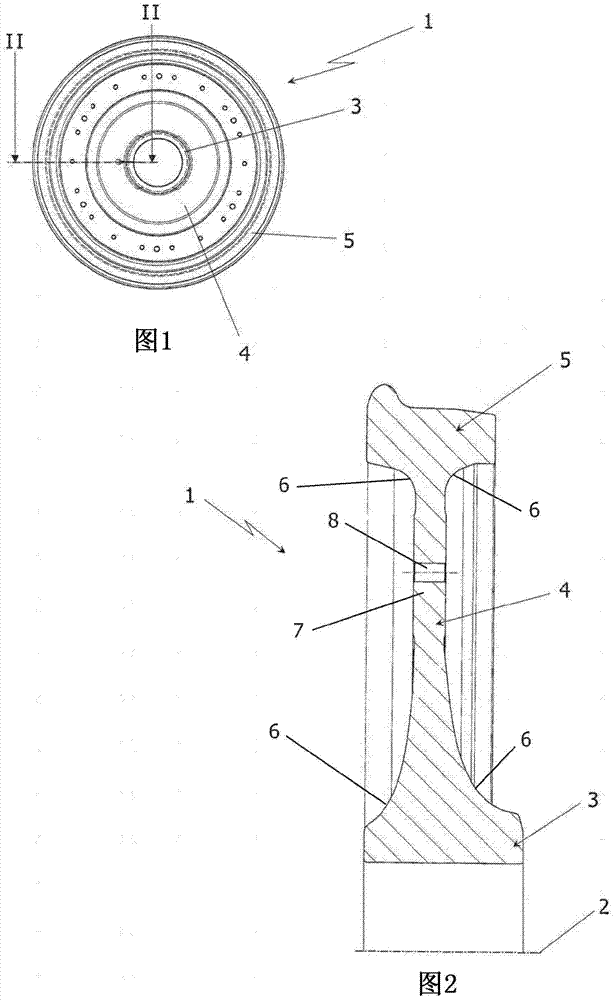

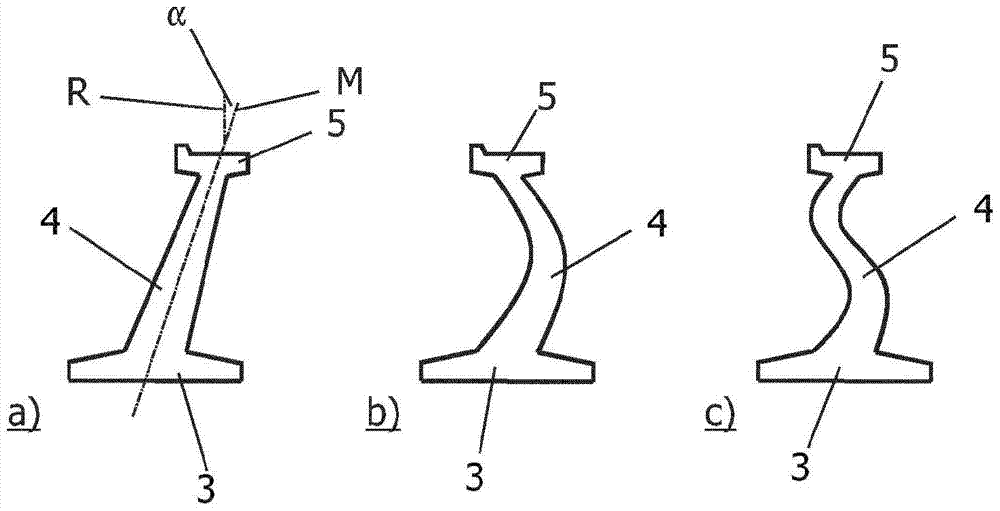

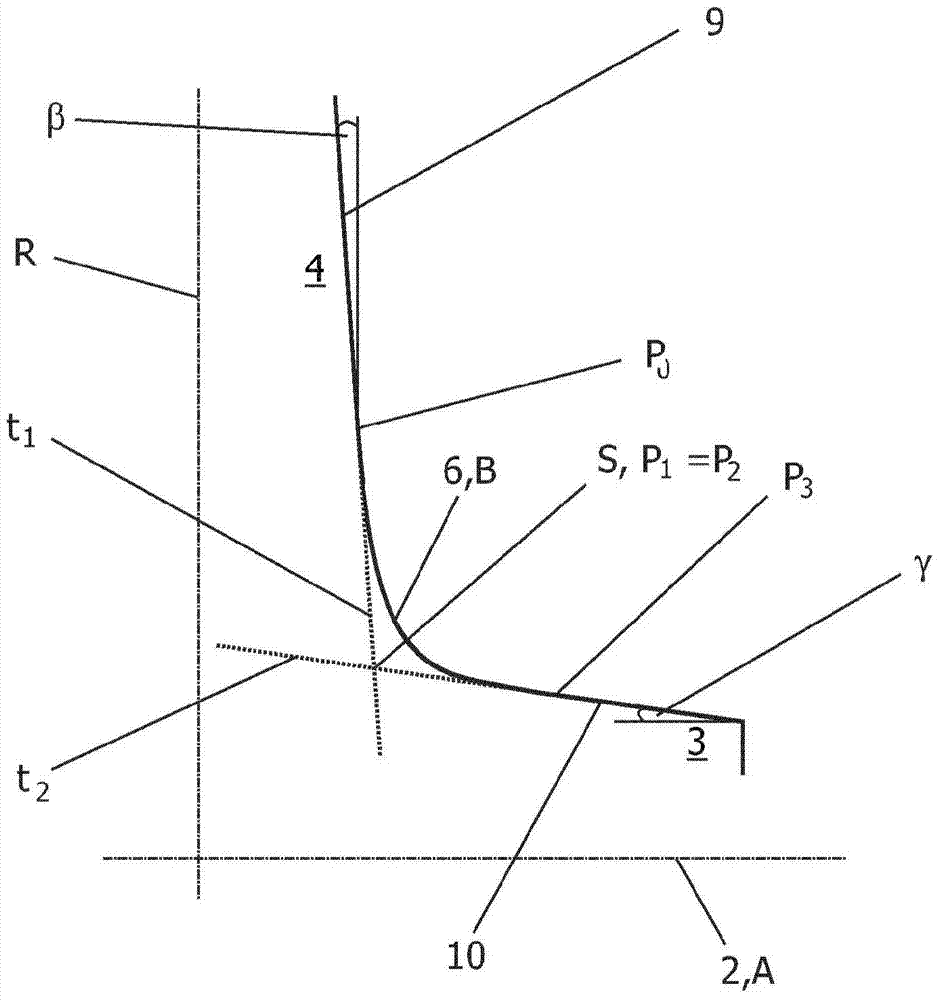

[0029] The side view of the wheel 1 can be seen purely by way of example in the illustration in FIG. 1. Such a wheel 1 is used as a wheel for rail vehicles. The structure is shown in detail by the section marked II-II in FIG. 1 which can be seen in FIG. 2. The structure shown in FIG. 2 can be used purely for illustrating the elements of the roulette here. The structure according to the present invention will later be used Figure 4 Will also elaborate. It can be seen in the radial section of FIG. 2 that the wheel disc 1 is composed of a hub 3 surrounding the axis of rotation 2. The hub 3 is connected via disc-shaped members called spokes 4 to a rim 5 that rolls on a track when the wheel 1 is used. This structure as it is shown in FIG. 2 is generally known and common. The illustration in FIG. 2 is a structure with so-called straight spokes 4 extending perpendicular to the axis of rotation 2 in the radial direction.

[0030] Instead of such straight spokes 4, other structures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com