Manual grouting layer method pile toe three-dimensional post-pressure grouting structure and pouring method

A technology of grouting layer and pile end, which is applied in the direction of foundation structure engineering, building, sheet pile wall, etc., can solve the problems of small amount of grouting, small number of grouting holes, and the grouting pipe is easily wrapped by concrete, etc., to achieve Good material availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

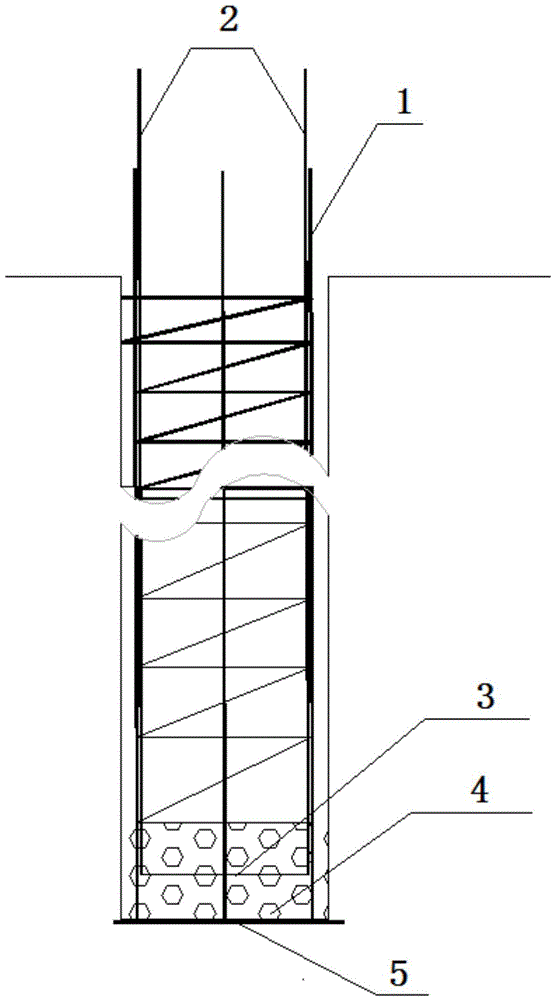

[0035] The present invention also includes a pouring method for the three-dimensional rear grouting structure at the pile end by the artificial grouting layer method, which includes the following methods,

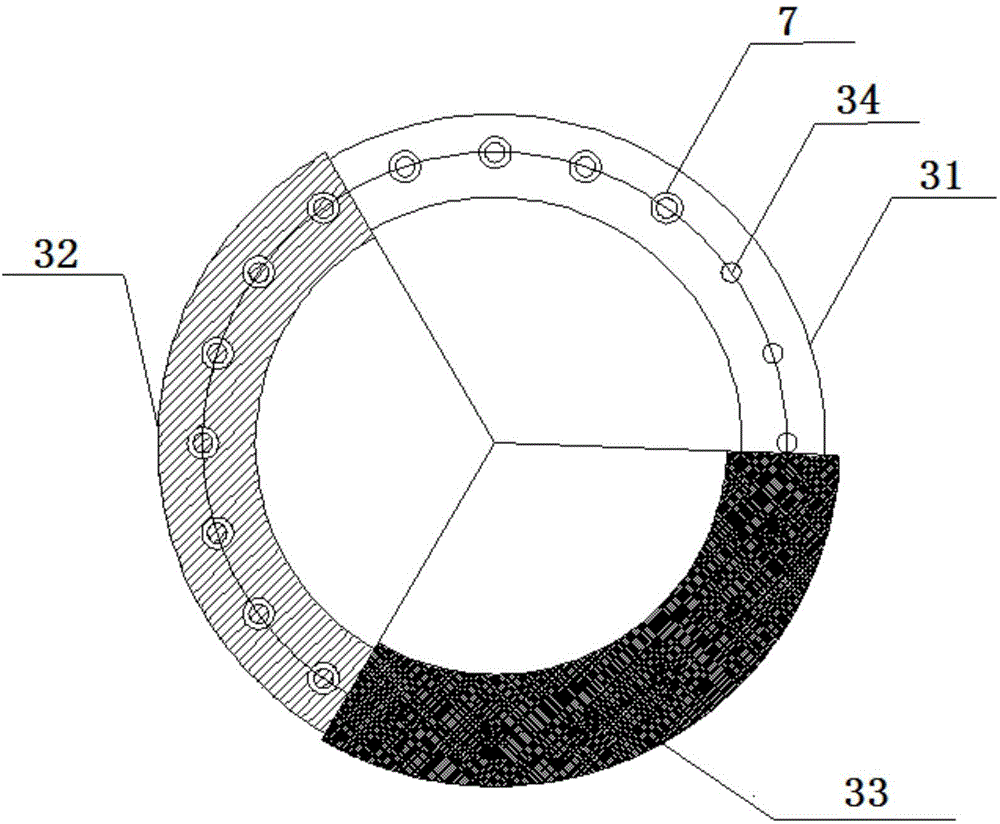

[0036]Prepare the annular grouting pipe, set a grout hole on the circular PVC steel wire pipe, press a thumbtack on the grout hole, wrap the car rubber inner tube outside, and wrap one or two layers of packing tape on the outside of the car rubber inner tube; The PVC steel wire pipe communicates with the grouting conduit through a communication valve. The rubber inner tube of the car is an ordinary bicycle inner tube.

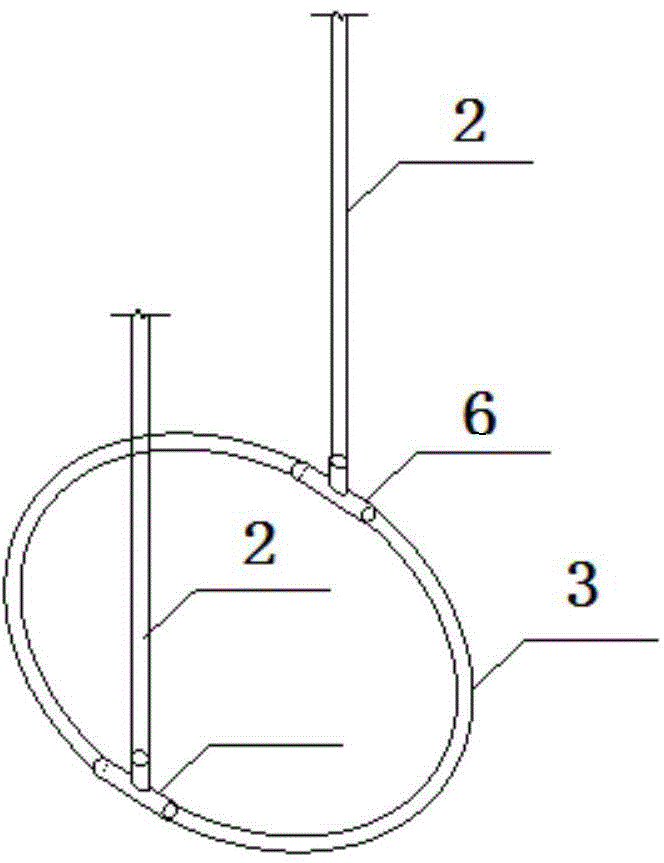

[0037] Bind the annular grouting pipe to the inner side of the main reinforcement of the reinforcement cage at a height of 20-30cm from the bottom of the cast-in-place pile;

[0038] After the annular grouting pipe is lowered to the design elevation along with the steel cage, first pour one or two trolleys of crushed stone or the amount of crushed stone tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com