a linear tower

A technology of straight towers and ground wires, applied in the field of straight towers, can solve problems such as long time for the power grid to return to normal work, long construction period for restoration and reconstruction of straight towers, and potential safety hazards, so as to avoid large-scale replacement of ground wires and conductors, and avoid Effect of tower collapse accident and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

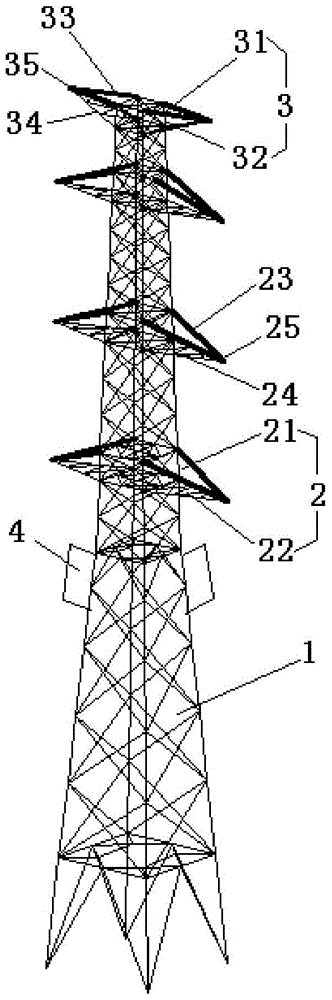

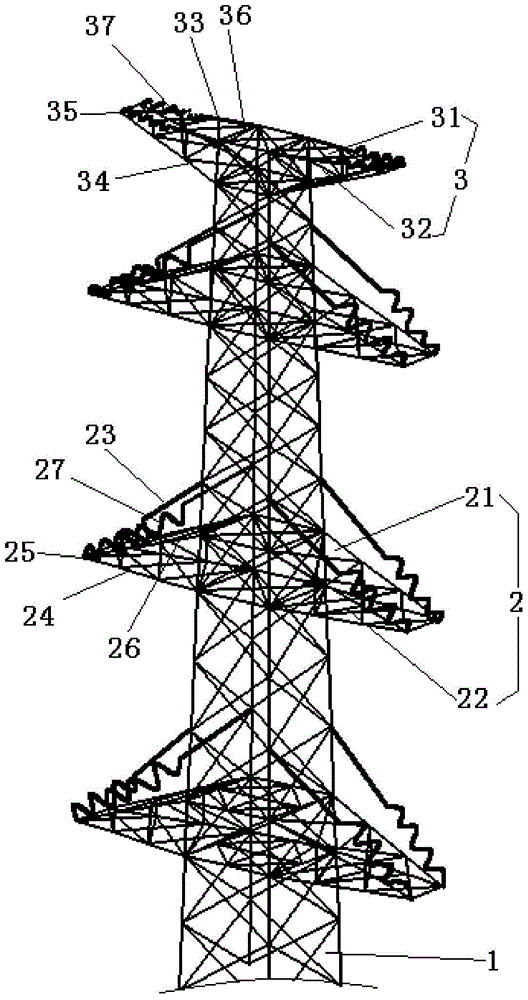

[0031] Such as figure 1 Shown, see also figure 2 , The embodiment of the present invention provides a linear tower, the linear tower includes: a tower body 1, a ground wire cross arm 3, a wire cross arm 2, a ground wire hanging point 35, a ground cable 33, a wire hanging point 25 and The wire cable 23, the ground wire cross arm 3 and the wire cross arm 2 are sequentially arranged on the tower body 1 from top to bottom,

[0032] The ground cross arm 3 includes at least a ground cross arm lower plane 32, the ground cross arm lower plane 32 includes at least a ground cross arm lower plane main material 34, and the ground wire cross arm lower plane main material 34 One end is fixedly connected to the tower body 1, and the other end of the ground wire cross arm lower plane main material 34 is provided with the ground wire hanging point 35, and the ground wire is erected through the ground wire hanging point 35. The safety level of the plane main material 34 under the ground cross ar...

Embodiment 2

[0053] Such as figure 1 As shown, this embodiment provides a linear tower for low-voltage power transmission lines, and the linear tower includes all the content in the first embodiment.

[0054] Such as figure 1 As shown, the ground cross arm 3 further includes a ground cross arm upper plane 31, the ground cross arm upper plane 31 is composed of the ground cable 33, and the ground wire cross arm lower plane main material 34 The safety level is lower than the safety level of the ground cable 33, the wire cross arm 2 also includes a wire cross arm upper plane 21, the wire cross arm upper plane 21 is composed of the wire cable 23, the The safety level of the plane main material 24 under the conductor cross arm is lower than the safety level of the conductor cable 23.

[0055] In this embodiment, since the length of the low-voltage line conductor cross arm 2 is relatively short, and the cross-sectional area of the ground wire and the conductor of the low-voltage line is smaller than...

Embodiment 3

[0060] Such as figure 2 As shown, this embodiment provides a linear tower for high-voltage power transmission lines, and the linear tower includes all the content in the first embodiment.

[0061] Such as figure 2 As shown, the ground cross arm 3 also includes a ground cross arm upper plane 31, the ground cross arm upper plane 31 includes at least a ground cross arm upper plane main material 36, the ground cross arm upper plane main One end of the material 36 is fixedly connected to the tower body 1, and the other end of the upper plane main material 36 of the ground wire cross arm is fixed at the place where the ground wire hanging point 35 is set on the lower plane main material 34 of the ground wire cross arm. The safety level of the upper plane main material 36 of the ground wire cross arm is equal to the safety level of the lower plane main material 34 of the ground wire cross arm. The wire cross arm 2 also includes the upper plane 21 of the wire cross arm. The upper pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com