Shear mode magnetorheological elastomer frequency conversion vibration isolator

A magnetorheological elastomer, vibration isolator technology, applied in the direction of shock absorbers, springs/shock absorbers, springs, etc., can solve problems such as hindering the work of springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

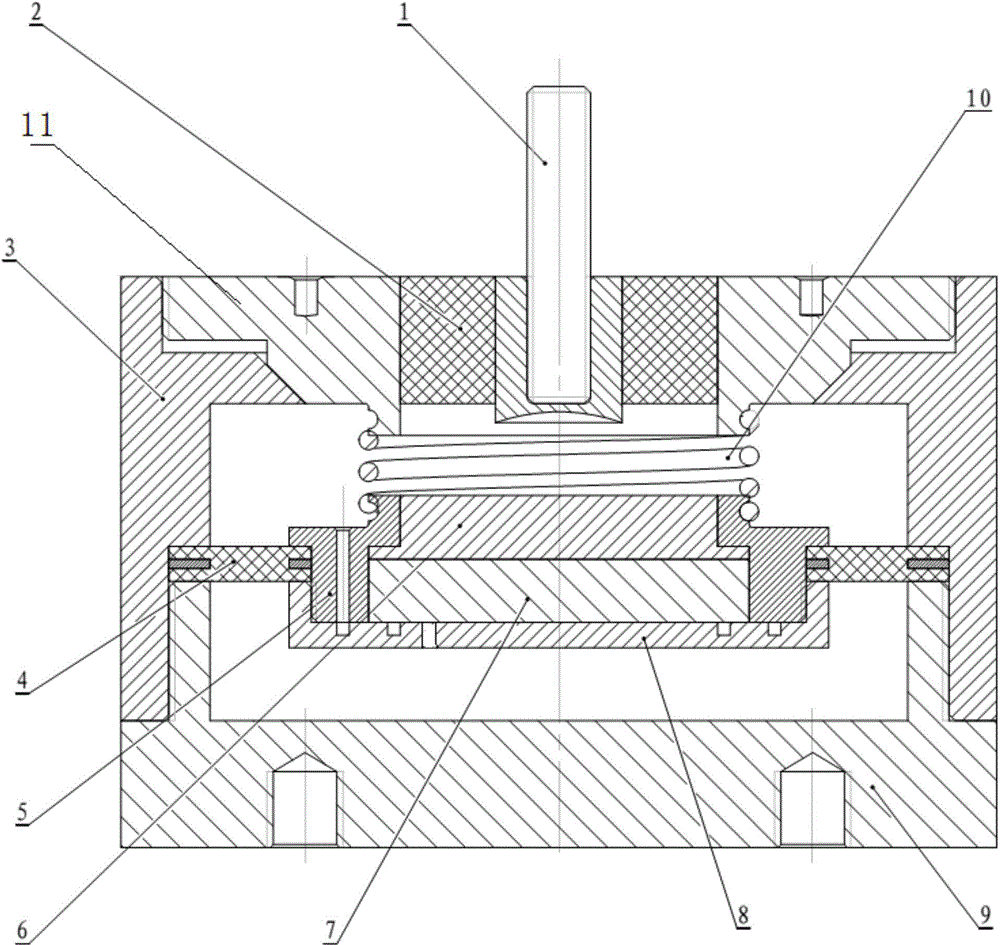

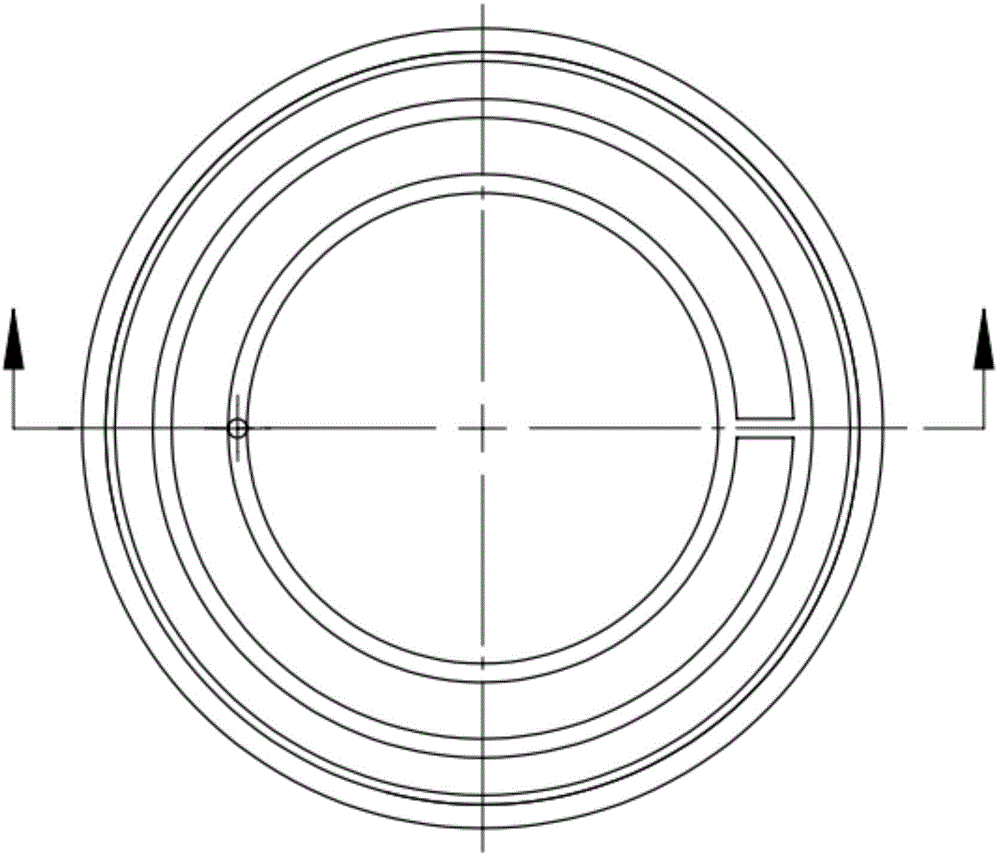

[0029] Such as figure 1 As shown, the shear mode magnetorheological elastomer frequency conversion vibration isolator includes a bolt 1, a magnetorheological elastomer 2, a housing 11, an upper cover plate 3, a lower cover plate 9, a sealing ring 4, a magnet block 6, Magnet 7, magnet cover 5, magnet cover plate 8, spring 10, described bolt 1 is fixed in the middle of magnetorheological elastomer 2 through the connection nut that aluminum alloy is made, and bolt material is brass, and described bolt 1 upper end installs power Assembly.

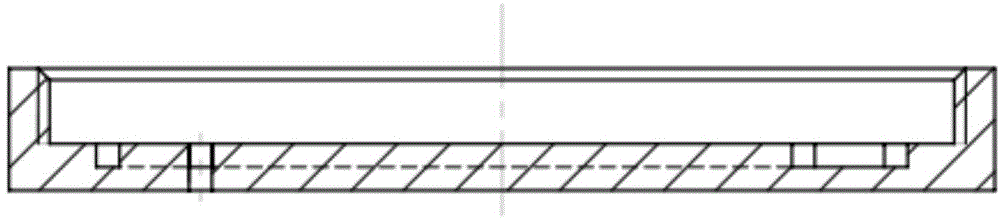

[0030] The magnetorheological elastomer 2 is vulcanized and bonded to the housing 11 to form a magnetorheological elastomer assembly. The two ends of the housing 11 are stepped, and the two ends of the housing 11 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com