A pulse-controlled micro-power position feedback bistable electric control valve

A pulse control, micro-power consumption technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of no position feedback, low power consumption, unstable state, etc., to achieve accurate and reliable drive control, The effect of simplifying drive requirements and reducing drive power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

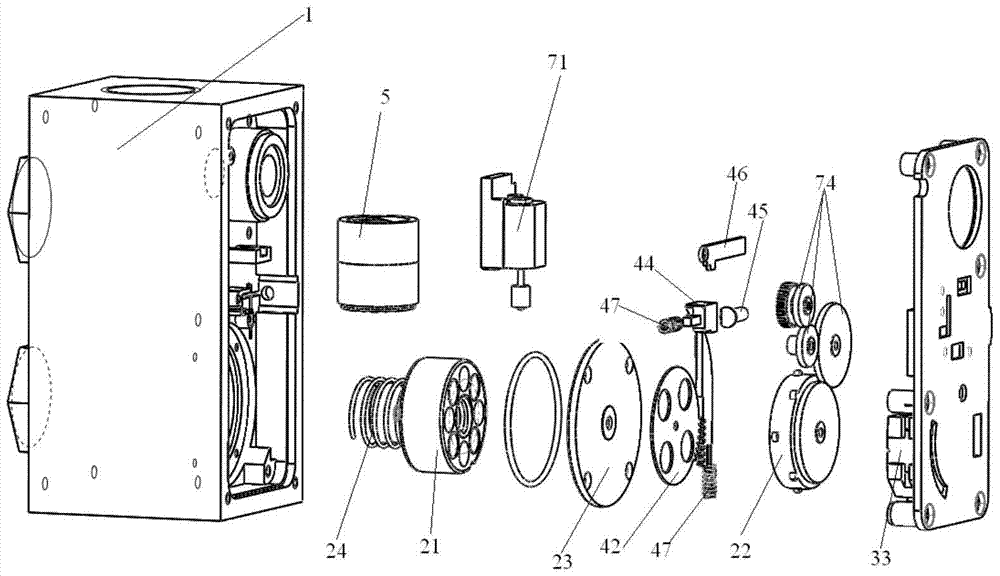

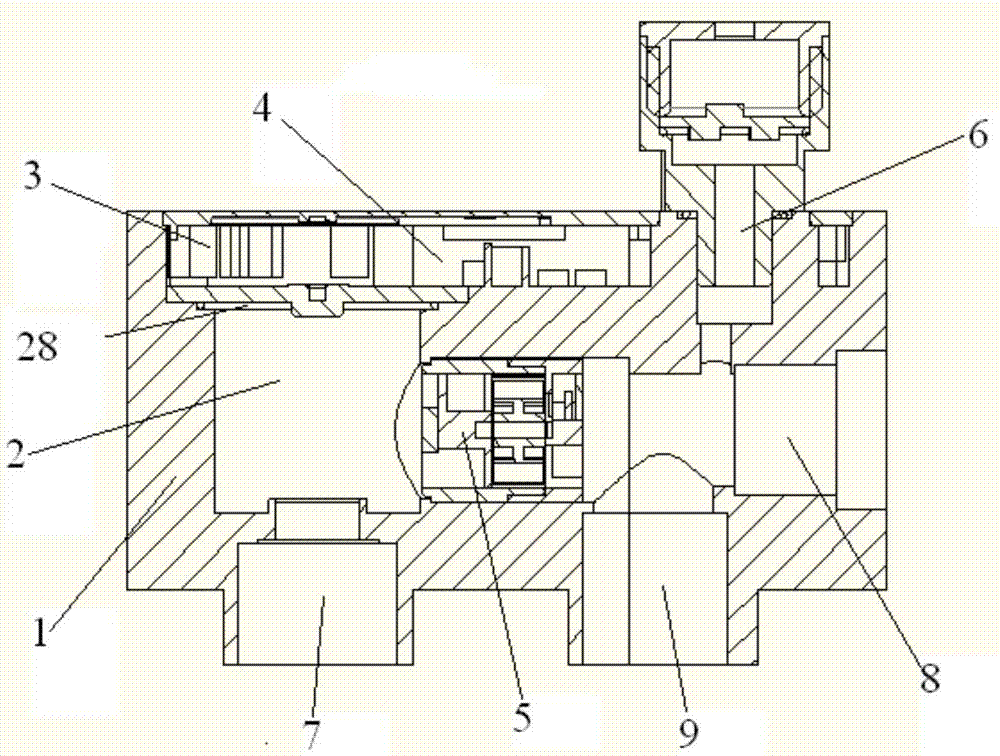

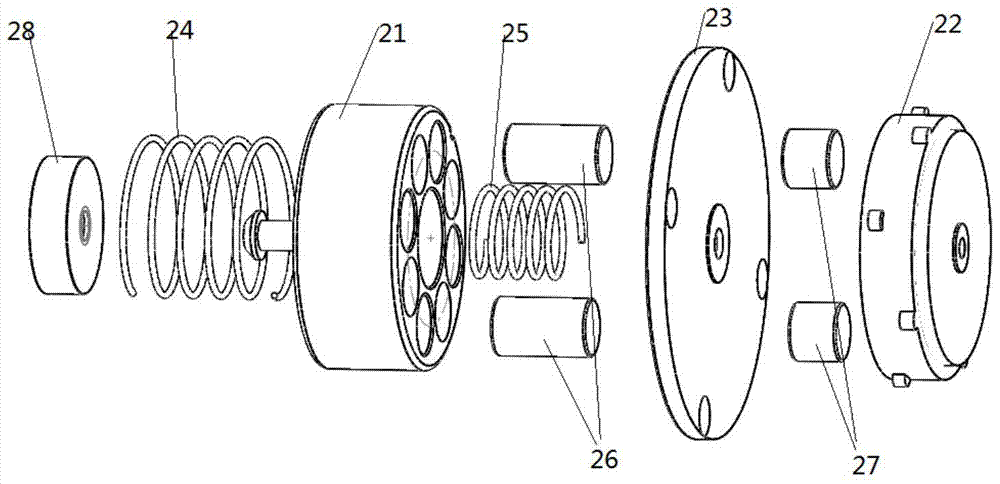

[0035] figure 1 with figure 2 Respectively, a schematic diagram and a cross-sectional view of the key components of a pulse-controlled micro-power position feedback bistable electric control valve of the present invention, including a valve body 1, a rotary magnetic switch structure 2, a position detection structure 3, and a magnetic clutch transmission structure 4. Flow sensor 5, pressure sensor 6, bottom inlet 7, side outlet 8, bottom outlet 9,

[0036] The interior of the valve body 1 is divided into two independently sealed chambers by the sealing ring and the moving core cover plate 23: the mechanism chamber and the entire fluid chamber; the fluid chamber is respectively composed of the bottom inlet 7, the action chamber, the flow sensor chamber, the pressure sensor installation port, The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com